Toxic substances are everywhere in the workplace, from cleaning products to manufacturing chemicals. While we understand that toxic chemicals have the potential to damage human health, there are multiple factors that you need to consider if you’re working with these Division 6.1 substances.

What is a Toxic Substance?

A toxic substance is a chemical or mixture of chemicals that can cause damage to the health of humans and other living organisms. The definition for Division 6.1 Toxic Substances is outlined in the Australian Dangerous Goods (ADG) Code as: “substances liable either to cause death or serious injury or harm to human health if swallowed or inhaled or by skin contact.”

How Toxic Substances Can Harm

As highlighted in the Australian Dangerous Goods Code’s definition, there are three main ways in which toxic substances can enter the human body and cause harm.

These routes of exposure for toxic chemicals include:

- Skin absorption – when toxic substances are spilled or splashed onto the skin or into the eyes of staff.

- Ingestion – exposure through ingestion may occur if toxic substances are unknowingly consumed, usually through small amounts remaining on the hands or gloves after handling.

- Inhalation – toxic fumes can cause human harm, affecting the brain and body, and damaging the lungs and respiratory system of those who may breathe them in.

Of these three routes of exposure, inhalation is the most common form within a working environment. This form of toxic exposure occurs when airborne toxic particles enter the lungs when workers who are simply working in the contaminated area.

Ingestion of toxic substances mostly occurs from unhygienic practices such as eating and drink with hands that have not been washed after handling toxic material. Skin absorption is the least common form of exposure and occurs when toxic substances are absorbed through your skin.

IMPORTANT: Due to the serious health risks associated with toxic chemicals, personal protective equipment including chemically-resistant elbow-length gloves, protective clothing and self-contained breathing apparatus must be available at workplaces where toxic chemicals are stored or handled.

Toxic Substances in the Workplace

There are a number of toxic substances that are used in the workplace on a regular basis.

Some of these toxic substances include methylene chloride, isopropyl alcohol and hydrogen peroxide.

To protect the people in your workplace from the many risks associated with toxic substances, you must ensure that your toxic substances are stored in a safe and compliant storage facility.

The Australian Standard that relates to toxic chemicals is AS NZS 445.

AS NZS 4452 Storage Requirements

The storage and handling of toxic substances is the Australian Standard outlines the specific requirements for Division 6.1 chemicals. In this post, we’ll be focusing on the indoor storage of toxic chemicals in the workplace through the installation of Class 6.1 toxic storage cabinets.

Refer to the Australian Standard for storage requirements specific to toxic substances.

Construction Requirements for Toxic Storage Cabinets

Section 4.4.2.3 of AS NZS 4452 sets out the construction and design requirement for toxic substance indoor storage cabinets.

These toxic substance cabinet construction requirements include:

- The roof, floor, door and walls of the cabinet must have a double walled sheet steel construction.

- The sheet steel must be at least 0.75mm thick.

- There must be a space of at least 40mm between the walls of the cabinet. This space may be an airspace or filled with a non-combustible material.

- The doors of the cabinet shall be self-closing and close-fitting.

- The doors of toxic substance storage cabinets shall be lockable.

- The bottom of the cabinet shall form a liquid-tight spill containment sump. This sump must be at least 150mm deep and capable of containing at least 25% of the maximum storage capacity of the cabinet.

- Any shelves inside the cabinet shall be perforated to allow for free airflow within the cabinet.

- Any materials that form the structural integrity of the cabinet must not melt at temperatures of at least 850°C. Seals and gaskets are an exception to this requirement.

Storemasta safety cabinets for toxic substances feature a range of controls to minimise hazards and human harm.

Ventilation for Toxic Substance Cabinets

The Australian Standard does not make ventilation of toxic storage cabinets a mandatory requirement, but it gives you the provision to do so if required.

If the toxic substance being stored is listed in the workplace exposure standards, and the concentration of the airborne contaminants from the toxic substances exceeds the maximum limit outlined in the workplace exposure standards, ventilation will be required.

Inhalation is the most common form of exposure to toxic substance and it’s a good practice to ventilate indoor toxic substance storage cabinets to minimise the risk of exposure to people in the workplace.

If you carry out a dangerous goods risk assessment and you determine that ventilation is required for your toxic storage cabinets, it’s important to ensure that the ventilation system that you install on your cabinets meets the specific requirements outlined in AS NZS 4452.

The ventilation requirements for toxic cabinets include:

- Any vent opening on the cabinet shall be designed in such a way that it does not compromise the structural integrity of the cabinet.

- The ventilation system on the cabinet shall be capable of keeping the ambient concentration of airborne toxic substances in the breathing zone of any person using the cabinet at the lowest limit possible.

Where a toxic storage cabinet has the provision to be connected to an external ventilation system:

- The vent opening shall be provided with the means of permanent closure when venting is not required.

- The information supplied with the cabinet shall include instructions on how to install and operate the venting system.

- The cabinet vent shall be designed in such a way that the surrounding work areas are not contaminated by emissions.

- The ventilation system shall also be designed by an appropriately qualified engineer.

Find out how to ventilate DG cabinets

Maximum Storage Quantities

To reduce the risk of exposure, whether this be by inhalation, ingestion or skin contact, it’s important to keep the quantity of toxic substances stored indoors to the absolute minimum.

Th Australian Standard states that the maximum storage quantities for indoor toxic substance storage is:

- A single cabinet shall not exceed 250 L or Kg.

- Of this 250 L or Kg that is stored in a single cabinet, no more than 50 Kg or L shall be of packing group II and no more than 25 L or Kg shall be of packing group I.

Class 6.1 Cabinet Location

To ensure that toxic storage cabinets protect people, property and environment, it’s important to position your cabinet in a safe location.

The positioning requirements for toxic storage cabinets is outlined below:

- A cabinet storing toxic substances shall not be installed in a location that impedes the escape of people in the event of a fire or hazard.

- A toxic storage cabinet must always be located near a provision for the washing of hands.

- Irrespective of the occupancy of the building, no more than one toxic storage cabinet shall be located in each 100 square metres of floor space. Each toxic storage cabinet must be separated by at least 3 metres.

Cabinet Marking

To ensure that everyone in your workplace, including visitors and workers, are aware of the hazardous toxic substances that are stored in your workplace, each toxic storage cabinet must display the relevant safety signage.

The safety signage requirements for toxic storage cabinets are outlined in Work Safe Australia’s Guidance Note for Placarding Stores for Dangerous Goods and Specified Hazardous Substances [NOHSC: 3009(1990)].

The only exception is when the requirements of Work Safe’s guidance note conflicts with the requirements of the relevant regulatory authority for your State or Region. In this situation the requirements of the state regulatory authority will prevail.

In all instances, the safety signage and lettering shall be of contrasting colour to the colour of the toxic storage cabinet.

REMEMBER: You should develop an inspection schedule to ensure that your toxic storage cabinets are being used and maintained in a safe and compliant manner. This includes checking for vapours, spills, leaks, the visibility of dangerous goods signage and all other controls that are necessary for the risk management of your kept substances.

Segregation from Incompatible Substances

Toxic storage cabinets should only be used for the storage of toxic substances.

A toxic substance is incompatible with many other classes of dangerous goods. Therefore, they must be kept in separate, designated safety cabinets to avoid hazards. If they aren’t kept in separate cabinets made for their dangerous goods class, they must be separated at a distance from incompatible chemicals as per the segregation guidelines.

REMEMBER: When incompatible dangerous goods mix or come into close range of each other, they can potentially cause hazards or chemical reactions. Conduct a risk assessment to determine suitable separation distances for incompatible substances. Also consider any type of fire risk with other dangerous goods onsite, so the proper precautions are put in place for separation.

Toxic Storage Safety

As toxic substances can cause harm to the people, property and environment of your organisation, you must store Class 6.1 chemicals in a compliant toxic storage cabinet. For maximum safety, it’s also important that you do your research on the compatibility of toxic substances with other classes of dangerous goods, so that you can segregate them in a compliant manner.

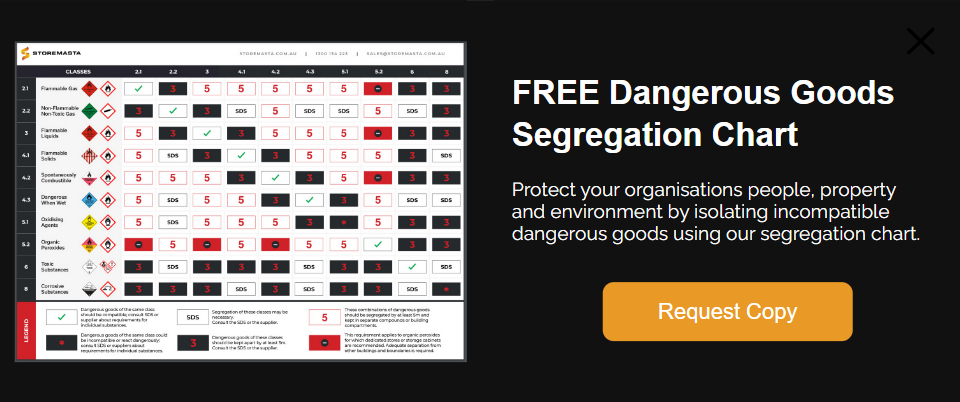

For more information on how to safely separate toxic substances from other incompatible classes of dangerous goods, download our free Dangerous Goods Segregation Chart. Our chart can help you identify incompatible substances and practice the safe segregate of chemicals at your own worksite.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.