When you hear the word ‘toxic chemical’, you may think of a polluted river, or plumes of toxins being expelled from a factory. However, toxic substances are everywhere – especially in the workplace. And how these substances are handled is crucial for the health and safety of staff, as well as others in the work environment.

In this post, we’ll be looking at how to handle toxic substances safely, with some key considerations that will help you reduce the risk of human harm.

But first, let’s look at toxic substances – and what they can do to the human body.

How Do Toxic Substances Harm Human Health?

Toxic substances pose a wide range of risks to human health, which can vary based on:

- The type of substance

- The level and duration of exposure

- The individual's health and genetics

Here are some key risks associated with exposure to toxic substances:

Acute Health Effects

Toxic substances can cause immediate health effects such as nausea, vomiting, dizziness, headaches, and respiratory distress. Many toxic substances can cause irritation, burns, or damage to the skin and eyes upon contact.

Ingesting or inhaling certain toxic substances can lead to poisoning, which may require immediate medical attention and can be fatal.

Chronic Health Effects

Prolonged exposure to toxic substances can cause damage to vital organs, including the liver, kidneys, heart, and lungs. Some toxic substances, such as asbestos, benzene, and certain pesticides, are known carcinogens and can increase the risk of developing cancer.

Exposure to toxic substances during pregnancy can lead to birth defects, developmental delays, and reproductive issues — in both men and women.

Toxic chemicals may create acute and/chronic health effects in humans or other living organisms.

In addition to the immediate health effects or long-term health effects of toxic chemical exposure, there are also a range of health issues that may be toxic substances.

These health effects include:

Neurological

Certain substances, such as lead, mercury, and some pesticides, can damage the nervous system, leading to cognitive impairments, memory loss, and behavioral changes.

Long-term exposure to neurotoxic substances may contribute to the development of neurological diseases like Parkinson's and Alzheimer's.

Cardiovascular

Exposure to certain toxic substances, such as air pollutants and chemicals in tobacco smoke, can increase the risk of cardiovascular diseases, including heart attacks and strokes. Some toxic substances can also affect blood pressure and contribute to hypertension.

Respiratory

Inhalation of toxic substances can cause respiratory issues such as asthma, chronic bronchitis, and other lung diseases. Some toxic substances can trigger allergic reactions and exacerbate conditions like asthma and allergies.

Due to the risk of respiratory illness, toxic exposure must be controlled with ventilation and breathing apparatus used during handling, if required.

Immune System

Certain toxic substances can weaken the immune system, making individuals more susceptible to infections and diseases. Long-term exposure to some chemicals may be linked to the development of autoimmune disorders.

REMEMBER: Toxic chemicals can be identified by referring to your chemical’s safety data sheet. Section 2 of your safety data sheets will outline the hazards of the substance, while Section 14 will give you the division or class of the dangerous goods. Toxic Substances are recognised as Divison 6.1 dangerous goods.

Handling Toxic Chemicals

Regardless of the dangerous goods that you’re carrying at your site, there are basic measures that must be applied to ensure that your staff aren’t harmed through the routes of exposure with your hazardous chemicals.

The routes of exposure are:

- Absorption – chemicals that make direct contact with the skin or eyes of staff can result in blindness, poisoning and chemical burns. Emergency decontamination equipment, such as safety showers and eye wash stations must be in place to reduce the likelihood of exposure.

- Inhalation – toxic vapours, fumes or dusts may be inhaled by staff who are working with them or in the work area. Ensuring that toxic chemicals are properly stored and handled, and that the correct PPE is worn, will assist with maintaining a safe air quality.

- Ingestion – the accidental ingestion of toxic substances may be fatal. Clearly marked containers and safe work practices, hygiene and handling protocols must be in place to prevent exposure and accidents.

To control toxic chemical exposure through these 3 routes of exposure — as well as prevent environmental harm if the chemical leaks or spills — there are a range of considerations to make to minimise risk.

Using the hierarchy of control, toxic chemicals must be controlled through a process of:

- Elimination of toxic substances from processes

- Substitution with a less harmful chemical

- The control of inventory of toxic chemicals onsite

- Storage, handling and ventilation to reduce risk

- Administration controls that restrict access to toxic chemicals and control exposure

- Personal protective equipment must be used when the hazard can’t be eliminated, and in addition to other control measures in the hierarchy.

Tips for the Safe Handling of Toxic Substances

To ensure the safe handling of toxic chemicals in the workplace, there are a wide range of controls that need to be put in place. These controls must be specific to the chemicals that you’re carrying – and the risks present in your workplace.

However, some general advice on toxic chemical handling includes:

Use the Correct Personal Protective Equipment

Toxic chemicals, by their very nature, are some of the most harmful dangerous goods. PPE – otherwise known as personal protective equipment – must be worn when working with toxic chemicals.

Always refer to the individual safety data sheet of each toxic chemical product to determine the most appropriate PPE for that substance, as these requirements may vary.

Types of compliant personal protective equipment that may be useful for toxic substances include:

- Eye protection

- Self-contained breathing apparatus

- Respirators

- Elbow-length gloves

- PVC or rubber boots

- Protective clothing

PPE should also be properly maintained, so that contamination does not occur when staff are re-using equipment. PPE Cabinets are a useful tool to keep personal protective equipment safe, in a designated location and readily available to staff.

Use a dedicated PPE Cabinet to store laundered toxic chemical personal protective equipment to ensure safety and efficiency.

REMEMBER: PVC is generally suitable for personal protective equipment for toxic substances, although it should be inspected and maintained to ensure safety. Refer to your chemical’s SDS for the appropriate PPE measures.

Conduct Air Monitoring & Maintain Good Ventilation

If your toxic chemicals are listed in the Safe Work Australia workplace exposure standards for airborne contaminants, you have a legal obligation to ensure your air quality remains within the limits.

To make sure that your workplace is a health and safe environment, you may need to conduct air monitoring to test the level of contaminants in the air. This can be done in consultation with specialist personnel, such as a qualified occupational hygienist. By regularly conducting air monitoring, you may be able to detect any hazards that will affect workers through inhalation.

In addition to monitoring, it’s also important to have good ventilation in your toxic chemical storage and handling areas. This may mean the provision for ventilation in storage areas – either natural ventilation in the outdoor environment or mechanical ventilation in indoor toxic cabinets.

Choosing storage to control vapour and spill risk, in addition to providing adequate ventilation, can assist with risk management with toxic substances.

The Australian Standard for toxic substances AS NZS 4452 explains that ventilation is dependant on the nature of the toxic substance as well as the circumstances of its use in the workplace. We recommend conducting a risk assessment to determine suitable ventilation for your stores and workplace.

IMPORTANT: Are you concerned about airborne contaminants within your indoor storage cabinets? Read our blog to learn more about the ventilation requirements for toxic storage cabinets.

Controlling Leak and Spill Risk

Managing toxic substance leaks and spills is vital for the health and safety of staff – as the chemical can attack the routes of exposure if it’s accidentally released.

Refer to your safety data sheet for specific instructions on accidental release control measures, but keep in mind that using the correct PPE, opening any windows or allowing for maximum ventilation, and securing the area from other staff or pedestrians is vital when working with spilled class 6.1 substances.

Toxic chemicals can spill any time they are being transported, handled, used or stored. To reduce these spill risks, we recommend:

- Using compliant toxic substance storage with spill containment

- Encouraging the use of handling equipment for containers and drums when they’re moving around the workplace

- Providing spill bunds when drums or IBCs are not in storage

- Installing floor bunding on any warehouse or factory floors to prevent chemicals from spreading outdoors

- Implementing good housekeeping practices for handling and storage areas, to reduce chemical residue and leaks

- Develop regular inspections to ensure packages are secure, stores are clean and staff are handling and storing the toxic chemicals in the right way

IMPORTANT: Storage is an important part in controlling leaks, spills and other hazards of toxic substances. Read our popular blog to learn more about Class 6.1 storage requirements.

Regular Training for Staff and Contractors

From site inductions through to follow-up training sessions, making sure that your team are aware of the dangers associated with toxic substance handling is essential for the safety of your workplace.

Educating staff about toxic handling practices may include information such as:

- How to identify a toxic substance via GHS labels and safety data sheets

- The hazards they may cause to health and environment

- If the toxic chemical is incompatible with other dangerous goods, requiring segregation

- Acceptable storage and handling procedures

- How to use toxic storage equipment and handling equipment to reduce risk

- Emergency and evacuation procedures relating to toxic substances and other dangerous goods onsite

- Emergency decontamination procedures and first aid

- The correct PPE and how to use it, maintain it and store the equipment

- How to ensure personal hygiene when working with toxic chemicals

REMEMBER: Toxic chemicals must never be present in a lunchroom or area where food is kept, eaten or prepared due to the risk of exposure. Always wash hands before eating and drinking, going to the bathroom, and leaving the workplace.

Handling Toxic Substances Safely

Due to the harm caused by Class 6.1 Toxic Substances, developing the correct handling procedures is a key part of your risk management strategy. Storage is also an important aspect of chemical safety, as well as the separation of toxic chemicals from incompatible chemicals.

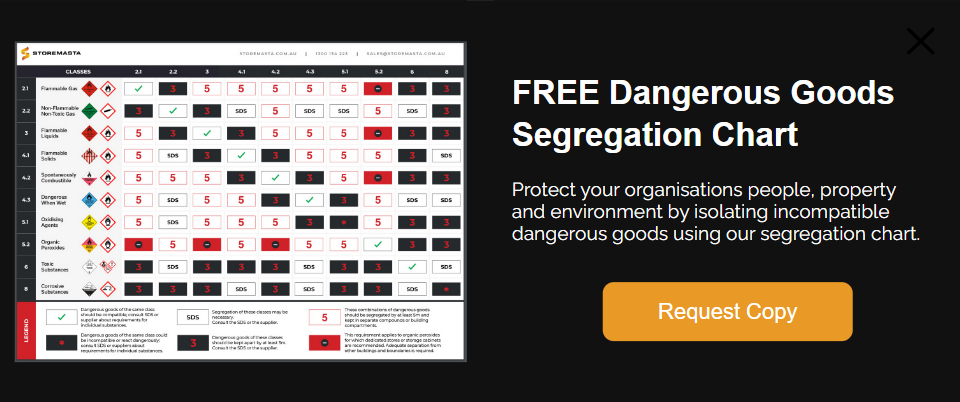

If you'd like more information on chemical segregation, you can access our free Dangerous Goods Segregation Chart. This chart will help you identify incompatible substances and practice the safe segregate of toxic substances and other dangerous goods at your own site.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.

%20(1)-1.jpg?width=650&height=433&name=SPP2%20Action%20photos%20edited%20(15%20of%2015)%20(1)-1.jpg)