The Hierarchy of Control is a method for deciding on effective control measures to implement at a workplace. It’s also a key requirement of Safe Work Australia’s Code of Practice: Managing risks of hazardous chemicals in the workplace. This post will help you understand how to approach hazard control measures by explaining how each control is ranked within the hierarchy. We’ll also show you how the Hierarchy of Control fits into a compliant risk management methodology.

Identifying and Assessing Chemical Hazards

Before you even begin thinking about implementing chemical risk control measures, you need to identify each of the substances kept at the worksite and assess how they could cause harm to your workers (or damage buildings, property, environment). Identifying chemical hazards and assessing their level of risk are the first two steps in a 4-step risk management methodology.

The 4 essential steps are:

- STEP 1: IDENTIFY all chemicals and the types of hazards they present (eg, health hazard/cancer, physical hazard/fire).

- STEP 2: ASSESS each of the chemical hazards and the severity of any dangerous events, injuries, or illnesses they could cause. You’ll finish this assessment step with a prioritised action plan based on the likelihood of each event.

- STEP 3: CONTROL use the Hierarchy of Control to determine the most effective ways to eliminate or minimise the risk. Then implement the controls.

- STEP 4: SUSTAIN compliance by implementing systematic reviews, safety auditing and scheduled maintenance.

IMPORTANT: Working through a risk management methodology ensures that each chemical hazard is correctly identified, with the level of danger fully assessed. The Hierarchy of Control is an essential step in the methodology and should not be used on its own.

What is the Hierarchy of Control?

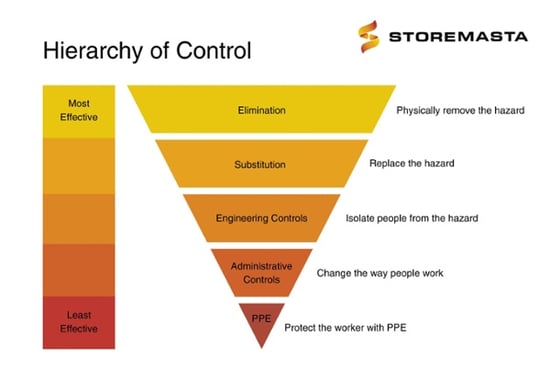

The Hierarchy of Control is a way of ranking risk control measures — from the most reliable and effective level of protection — to the least.

When controlling chemical hazards, the first step is always elimination.

Eliminating the chemical completely is always the most desirable approach. However, if this is not practicable, you should assess other control methods and work your way down the Hierarchy of Control in a systematic manner.

The Hierarchy of Control lists the following control measures:

- Elimination — elimination controls are the first step in the hierarchy. This elimination process is when a workplace stops using a hazardous chemical and completely eliminates that work process.

- Substitution — substitution controls are when another less harmful chemical or substance is used instead of the current hazardous chemical.

- Isolation — isolation controls include separating the chemicals from workers.

- Engineering — engineering controls include the use mechanical devices (such as chemical storage or handling equipment) or processes to minimise exposure to the chemicals.

- Administration — administrative controls include the implementation of safe work methods and operating procedures.

- Personal Protective Equipment — ensure that staff wear personal protective equipment while handling, transferring or using the chemical.

IMPORTANT: Administrative controls and personal protective equipment are the least effective as they rely on human behaviour. People forget, make mistakes, or sometimes just refuse to follow instructions. If possible, these control measures should accompany and reinforce other controls.

How to Use the Hierarchy of Control

When identifying and assessing control measures you should consider all 6 ranks in the Hierarchy of Control. If the chemical hazard can’t be eliminated, you will have to implement more than one control measure.

The best way to illustrate how to use the Hierarchy of Control to minimise chemical hazards in the workplace is to provide an example that you may find in a real world situation. In the next section of our post, we’ll lead you through this example and show you how to control the hazards in a methodical step-by-step manner.

HAZCHEM Controls: Workplace Example

A manufacturing plant uses a highly toxic and corrosive chemical in their manufacturing processes. The chemicals are kept in large vats with lids. The chemical vats are located in an open work area that’s accessible to staff and contractors.

Recently, a worker stood on one of the lids while doing some repairs. The lid subsequently collapsed under the weight of the staff member — and they fell in.

Using the Hierarchy of Control, let’s consider the effectiveness (and practicalities) of possible control measures.

PLEASE NOTE: This is a hypothetical example, although it resembles an actual incident that took place in the USA. The purpose of the example is to demonstrate how to approach the HOC rather than offer practical control methods.

- Elimination — the best method would be to stop using the hazardous chemical completely. In simpler examples sometimes this can be achieved by outsourcing or following a different line of business. But if your enterprise requires a specific chemical for manufacturing your core products, elimination will not be impossible (unless you shut down your operations). This hazard is a combination of the presence of a chemical and workers standing on top of the vat, so you should also look at ways of eliminating the need to stand on the vat.

- Substitution — the next level of protection is to consider alternative chemicals or materials that could be used in the manufacturing process. When substituting chemicals, you need to determine if the new substance could introduce additional hazards to the job site. For example, the new chemical may be less toxic, but it may be more reactive to heat or it may have a pungent smell.

- Isolation — consider if you could isolate the chemical from workers? Could you place the chemical vats in rooms operated remotely by robots or mechanical devices? Perhaps you could restrict access to the manufacturing floor and reduce the amount of personnel exposed to the chemicals. A chemical hazard would still exist but there now might only be 5 workers exposed to the chemical vats instead of 75.

- Engineering — engineering controls are an important part of the hazard control process. Consider what type of mechanical devices or machinery could minimise exposure to the chemicals? Could you devise a way to fully contain the chemicals in the vats then drain the individual vats before maintenance is carried out? Could you manufacture another platform over the lids, so that workers never stand directly on the vat? Similar to ‘substitution’ control measures, you’ll also need to assess if new hazards have been introduced by the engineering controls. For example, could someone accidentally open the lid to a vat that had not yet been emptied?

- Administration — administrative controls, like safe work methods and operating procedures, support other control measures. However, administrative controls should never be used in isolation. For example: an operational procedure may restrict access to the vats, but you may also have to provide security measures, such as fencing or gates with keypad entry, to provide the necessary physical barriers to deter unauthorised entry.

- Personal Protective Equipment — even if you had staff wearing full protection suits, workers could still fall into that vat of chemicals. Personal protective equipment is vulnerable if it doesn’t fit; gets lost, forgotten, stolen; or if it is damaged or torn while being worn. Personal protective equipment must never be used as a single control measure.

IMPORTANT: Once you decide on your control measures and implement them the operations of your workplace, make sure you conduct another risk assessment to ensure the effectiveness of the control measure.

Understanding Control Measures

This blog has introduced you to the Hierarchy of Control and given you an understanding of how each effective control measure is ranked in order of reliability and protection. To help you further control hazards in your own organisation, we suggest reading our eBook How To Manage The Risk Of Hazardous Chemicals In The Workplace. This free online resource will help you maintain compliance with Australian WHS legislation and Safety Standards by teaching you how to include these hazard control measures into your site’s risk management plan. Access your copy for free now to learn how to effectively lower your HAZCHEM risks.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.