Do you fully understand all the chemical hazards that may be present in your workplace? As Dangerous Goods Storage Specialists, one of our primary goals is to help our customers better understand what hazards they’re facing — before they set up their flammable liquids store. Safety cabinets, closed lube stations, bunding and subsidiary storage equipment are all engineering and isolation controls. They are specifically designed to keep hazardous chemicals stable and reduce human contact with Dangerous Goods. If your business is focused on providing a greater level of protection for your workers, read on to find out what engineering and isolation controls can support the safety of your flammable liquids store.

What Are Hazard Controls?

So, you’re ready to set up your flammable liquids store with a safety cabinet? Want to install a lube station on your worksite? That’s great news. But let’s backtrack for a second, as you may have missed a couple of crucial steps in chemical compliance.

It’s important to identify all chemical hazards through a risk assessment before you install your safety cabinet.

It’s important to identify all chemical hazards through a risk assessment before you install your safety cabinet.

While your safety equipment can undoubtedly save lives (as well as thousands of dollars due to waste reduction), you must first complete a risk assessment of your workplace.

But why? Well, if you’re going to implement the most effective risk control measures, you must first identify all the chemical hazards that are present in your workplace.

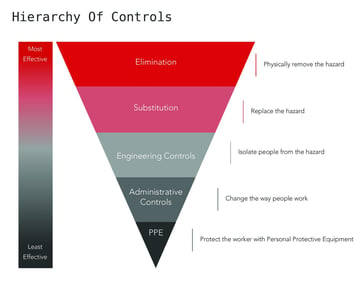

The Hierarchy of Controls, which is referred to in WHS Regulations and the HAZCHEM Code of Practice, recommends eliminating chemical hazards as the first step in the risk control process.

The first step in the Hierarchy of Controls is to determine if you can eliminate the chemical risk in your workplace.

If elimination of hazardous chemicals is not possible for your organisation, then you can take further steps to minimise the chemical’s potential for harm.

Here’s all the hazard control steps in the Hierarchy of Controls:

- Elimination - changing work processes and production outputs so you can stop using a chemical completely.

- Substitution - switching to chemicals that are less harmful (eg, higher flashpoint/autoignition temperature, less toxic, or non-corrosive).

- Isolation — placing distances or physical barriers between the chemicals, people, ignition sources and incompatible substances.

- Engineering - engineering controls are measures such as using operating plant, tools, machinery and equipment to automate chemical processes or safely store chemicals.

- Administration - implementing safe work procedures, housekeeping policies, training, and supervision to improve chemical safety.

- PPE - having workers wear chemical resistant goggles, masks, gloves, and boots to minimise chemical exposure.

Single hazard controls are rarely effective without the support of additional measures.

So, if your business regularly uses Class 3 Flammable Liquids, you should first determine if elimination is indeed a valid option. The next step in the Hierarchy of Controls is to then consider safer chemical alternatives, where possible.

For example, you could stop using your flammable liquids and substitute them with a chemical that has a:

- Higher flash point (ie less flammable chemical)

- Weaker concentration

- Less toxic properties

By choosing to eliminate a chemical hazard by finding an alternative, you could make a significant difference to the overall safety of your job site.  Your flammable liquids cabinet may require additional engineering and isolation controls to ensure safety and compliance.

Your flammable liquids cabinet may require additional engineering and isolation controls to ensure safety and compliance.

Isolation Controls For Flammable Liquids

An isolation control is a way of separating hazardous chemicals from people, other chemicals, Dangerous Goods and ignition sources.

Isolation controls are most effective during the design stage: when you’re designing a new warehouse, chemical store or construction site.

During the design phase, consider isolation controls for your flammable liquids store, such as excluding ignition sources from the area.

During the design phase, consider isolation controls for your flammable liquids store, such as excluding ignition sources from the area.

A simple isolation control to support your flammable liquids store and lube station is to stop workers from bringing any ignition sources into the area. This includes prohibiting hot work and tools (that produce sparks) within a 3 to 5 metre radius of your flammable liquids storage installation.

But there are many other isolation controls that you can use:

- Restricting access to chemical intake, storage, handling, decanting and waste holding areas. This can be achieved through a combination of administrative systems, and physical restraints (gates, fences, barrier walls).

- Placing oxidisers and other incompatible substances in their own, fully enclosed safety cabinets — or keeping them at least 3-5 metres from flammable liquids.

- Installing fire resistant screen walls to act as a vapour barrier between working quantities of flammable liquids.

- Using enclosed lubrication and decanting systems that fully contain the chemical containers and provide reliable spill protection.

An effective isolation control measure is to provide a lube station for the safe and compliant transferring of flammable liquids.

Engineering Controls For Flammable Liquids

Engineering controls utilise machinery, tools, and equipment to minimise exposure to hazardous chemicals.

Flammable liquids cabinets themselves are classed as engineering controls because they fully contain the liquids and flammable vapours within the safety cabinet.

Your flammable liquids cabinet is an engineering control that contains hazardous liquids and vapours.

Your flammable liquids cabinet is an engineering control that contains hazardous liquids and vapours.

However, you can also use additional engineering controls to improve safety and efficiency in chemical storage areas.

There are many ways that you can do this, such as reducing the distances that the chemical has to travel to be transferred or decanted, using mechanical lifting and carrying aids, and implementing spill bunding for safe chemical containment.

These additional engineering controls can reduce chemical spill waste and minimise the possibility and impact of chemical exposure. These controls also provide the additional benefits of encouraging increased productivity and workplace efficiency through their innovative design.

Engineering controls such as mechanical ventilation can assist in lowering chemical concentration levels.

Engineering controls such as mechanical ventilation can assist in lowering chemical concentration levels.

You might consider introducing the following engineering controls in your workplace:

- Installing a mechanical ventilation system that includes LEV (local exhaust ventilation) to reduce chemical concentration levels and carry away flammable vapours.

- Using equipment, machinery, and manufacturing processes that lower the temperature of chemicals (and work areas).

- Installing safe electrical fittings, circuits and equipment to reduce electrical discharge and ignition hazards.

- Using sensors, alarms and automated controls that regulate pressure and heat to minimise the likelihood of chemical overflow and the formation of hazardous atmospheres.

- Installing approved lighting in chemical handling and storage areas so chemicals can be easily identified and handled without error.

- Having spill kits located onsite that include absorbent materials, clean-up equipment and PPE.

- Installing fire detection and control systems.

- Using spill trays, under-pallet bunding, drum dollies, caddies and trolleys to contains leaks and spills from chemical drums, IBCs and smaller containers.

.png?width=312&name=Untitled%20design%20(21).png)

Using additional control measures such as bunding and drum trolleys can improve both safety and efficiency in your workplace.

What Engineering or Isolation Controls Does Your Workplace Require?

Now that we’ve explained how engineering and isolation controls can help improve your chemical compliance, we’d like to share our helpful eBook, Essential Considerations When Storing Flammable Liquids Indoors. This simple and straightforward guide offers practical advice for carrying out a risk assessment — so you can confidently identify every chemical hazard that you have onsite. Our free eBook also details what you should consider when you’re choosing a cabinet, so you can create a safe, efficient and 100% compliant flammable liquids store. Learn more about the safe storage of flammable liquids by accessing our eBook today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.