An important step in chemical safety is ensuring the isolation and segregation of hazardous chemicals. By using the Hierarchy of Control as your framework, you can assess and introduce control measures to eliminate or minimise workplace risks and hazards. As an accepted methodology for the systematic control of risks in the workplace, the Hierarchy of Control is a helpful tool to assist in achieving workplace compliance. In this post, we’ll be focusing on the isolation step by offering tips on how you can approach chemical hazard control in your own workplace.

What Is The Hierarchy of Control?

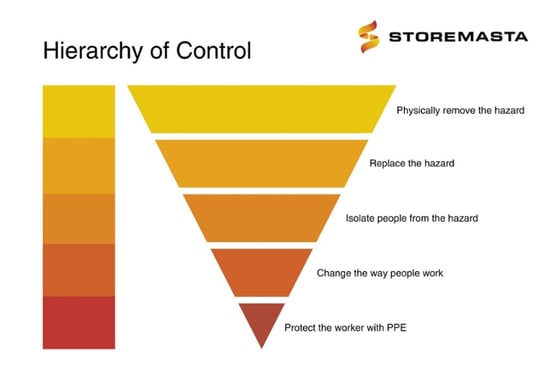

The Hierarchy of Control is simply a sequence of 5 or 6 control measures, ranked in order from most effective to least effective.

When you’re tasked with assessing a chemical hazard in your business, you can use the Hierarchy of Control to systematically work your way through the sequence.

This step-by-step methodology allows you to control chemical hazards through the elimination and substitution of hazardous substances, as well as the implementation of engineering controls, administrative controls and personal protective equipment.

IMPORTANT: When using this methodology, start at the top of the Hierarchy of Control and work your way towards the bottom. The top of the Hierarchy indicates the highest level of effectiveness when dealing with workplace risks.

Isolation Control

As a risk control measure, isolation focuses on physically separating chemicals from workers, as well as segregating chemicals from other incompatible substances.

Isolation is essential for the safe storage of hazardous substances.

Examples of isolation controls for hazardous chemicals include:

- Correctly segregating chemicals into compatible hazard classes

- Implementing the correct segregation distances between incompatible chemicals

- Storing chemicals in compliant safety cabinets or chemical stores

- Locating chemical stores away from potentially hazardous activities — like anything that could ignite or fuel a fire

- Minimising the number of workers who use or can physically access the chemicals

- Using physical barriers to keep people away from the chemicals

IMPORTANT: Separating and segregating certain hazardous chemicals and Dangerous Goods is a requirement of some Australian Safety Standards (eg, Flammable Liquids, Compressed Gases). You should also always check Section 16 of the chemical’s Safety Data Sheet for relevant legislation, codes or practice and safety standards.

Isolating Workers From Hazardous Chemicals

If your business can’t eliminate hazardous chemicals from daily operations, you can still reduce the risks associated with these chemicals.

Isolating your staff from the risks of hazardous chemicals can include restricting access to chemical handling and storage areas.

When it comes to the isolation of workers from hazardous substances, you can implement specific measures that limit the amount of contact workers (and other personnel) have with the chemicals.

Some effective examples of isolation controls include:

- Work with a fume hood or fume cabinet to extract harmful vapours

- Using closed or sealed systems for chemical dispensing and transfer

- Carrying out certain mixing and experimental works in a glove box or glove bag

- Restricting the amount of chemicals kept in work areas by storing them in safety cabinets or bulk stores constructed to Australian Safety Standards

- Performing certain tasks in enclosures fitted with exhaust extractors that remove air-borne contaminants while the operator is working

- Working from a positive pressure room which cannot be penetrated by air-borne contaminants

- Restricting access to chemical storage and work areas

Segregating and Separating Chemicals

Hazardous chemicals should always be physically separated from incompatible materials and substances, as well as those that can react dangerously.

Without such segregation controls, chemicals can create hazardous situations which may impact the health and safety of workers, as well as the surrounding environment and community.

You can achieve the successful segregation of hazardous chemicals by implementing physical barriers between incompatible classes and divisions, or chemicals that can react dangerously. However, it's vital to check your safety data sheets (SDS) as some chemicals may not be suitable for storage even within those of the same class or division.

By clearly identifying substances and how they should be stored, you can create safe working distances for staff to use and handle these dangerous goods.

Unsure about chemical segregation?

Isolating Chemical Stores

Where possible, chemical stores and handling areas should be strategically located away from key operations.

In many cases, isolating chemicals by distance only minimises the number of workers potentially exposed; there will still be people who actually handle the chemicals or transfer materials in and out of a chemical store.

There are specific requires that relate to the location of your chemical handling and storage areas.

Australian Safety Standards set specific separation distances for many chemicals, however, you can expect that your chemical stores should be located at least 3-5 metres away from:

- Site boundaries and protected places (residences, places of worship, schools etc)

- Combustibles, refuse, and vegetation

- Ignition sources and industrial heat

- Building openings (windows, doors, vents, ducting)

- Other chemical stores, decanting and transfer stations

You must locate your chemical stores away from site boundaries and protected places.

Segregating Chemicals and Dangerous Goods

Chemicals should always be sorted into hazard classes eg, flammable liquids, corrosive substances, toxic chemicals or compressed gases.

Some incompatible chemicals must be completely isolated, while others can be segregated within the chemical store.

IMPORTANT: Empty and full chemical containers are usually stored separately, with the empties clearly marked. Compressed gases, in particular, have specific requirements for their separation and storage.

Creating Physical Barriers

While it’s vital to ensure that your hazardous chemicals are stored a safe distance from significant locations, buildings and public places, you can store some hazardous substances in the same store — if a physical barrier is created.

This physical barrier may be a fully contained chemical cabinet (eg. a corrosive cabinet made from polyethylene, that has a segregated section for the storage of acids and bases). Alternatively, a physical barrier may be a screen wall erected inside the chemical store. The wall may need to be fire rated.

![]()

Polyethylene cabinets can be manufactured with a segregation barrier for acids and bases.

Screen walls must be constructed from non-combustible materials. They must also be impervious to the chemicals stored on either side.

If you check the Safety Standards for the relevant substance, you’ll find exact specifications that relate to these physical barriers.

Training Staff in Chemical Storage and Housekeeping

If your control measures aren’t implemented effectively by staff, supervisors and management, they can’t protect you from the hazards associated with your onsite chemicals. For example, if your workplace installs an under-bench acid cabinet, you must also train lab staff not to leave acids and corrosives lying around on bench tops.

Training is essential if you want your chemical controls to be used and maintained properly.

The implementation of chemical controls requires proper staff training sessions, regular reviews, and consistent supervision in order for the controls to effectively do their job.

EXAMPLE: Your workplace has purchased flammable liquids stores. To protect your people, you’ve introduced restricted access, so that only ‘Group A workers’ are able to access the areas. The stores have been installed in strategic locations, outside and away from manufacturing operations.

You’ll now want to ensure that:

- Site plans are updated with the locations of the new flammable liquids stores

- Operating procedures are developed and issued so all workers (especially Group A workers) understand the access restrictions

- Staff are advised in updated Site Inductions, job specific training, and remedial training

- Workers are supervised and provided with remedial training (or disciplinary action) if procedures aren’t followed.

Isolation Controls In Your Workplace

For a more detailed discussion of the Hierarchy of Control, or guidance on how to introduce a compliant risk management methodology to your workplace, why not download our free eBook? How To Manage The Risk Of Hazardous Chemicals In The Workplace offers detailed advice on how to identify and assess chemical risk, as well as how to implement controls. If you want to get your workplace 100% chemical safety compliant, download your copy today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.