From pesticides to cleaners, toxic substances are an unavoidable chemical in many homes and workplaces. The definition of a toxic substance is a chemical that can harm human health or, at worst, cause death or serious injury through routes of exposure — such as dermal absorption, oral ingestion or inhalation into the lungs.

When managing chemical toxicity in the workplace, it’s vital that diligent handling and storage practices are implemented and maintained. However, before these processes are put in place, you must first understand the toxic chemical/s that you’re working with —and be able to clearly identify the hazards that require control.

REMEMBER: Chemical toxicity is the degree of harm caused to a living organism due to exposure to a chemical substance. The toxicity level of your substances will affect how you handle and store the chemicals at your site.

Examples of Toxic Substances

So, how are toxic substances used in workplaces? There are a range of applications for toxic substances, across a broad range of sectors.

In the next section of our post, we’ve created a toxic chemicals list to help you understand some of the chemicals that pose harm to your staff. You’ll see that we’ve included some of the most common examples of DG Class 6 substances — and their various uses in a work environment.

| Toxic Substance | Chemical Formula | Industrial Application |

| Isopropyl alcohol | C3H80 |

|

| Hydrogen peroxide | H202 |

|

| Hydrogen sulfide | H2S |

|

| Methylene chloride (Dichloromethane) | CH2C12 |

|

| Sodium cyanide | NaCN |

|

| Chlorine | C1 |

|

| Mercuric chloride | HgC12 |

|

Effects of Toxic Chemicals

If there is an incident of toxic chemical exposure in a workplace, immediate action must be taken. Health effects caused by toxic chemicals may include short-term and long-term issues.

Short-term health effects may include:

- Nausea

- Headaches

- Rashes

- Chemical burns

- Poisoning

Long-term health effects may include:

- Weakening of the immune system

- Damage to organs

- Cancer

- Reproductive issues and birth defects

- Nervous system disorders

- Mental, physical or intellectual impairment

Toxic chemicals are known to cause both immediate and long-term health issues in those who suffer exposure to these dangerous goods.

What is the Classification for Toxic Substances?

With the danger they pose due to their acute lethal effect, many toxic substances are classified by the Australian Dangerous Goods (ADG) Code as Class 6.1 Dangerous Goods.

Toxic substances can cause long-lasting or chronic health issues such as cancer and liver disease, even if low-level exposure occurs over a long period of time.

Subsidiary Risks for Class 6 Dangerous Goods

Almost one-third of the dangerous goods classified as toxic substances in the ADG Code also have a subsidiary risk of another class (specifically Classes 3, 4, 5 or 8).

NOTE: Other toxic substances can be dangerous goods of Classes 1, 3, 4, 5 and 8 with a subsidiary risk of Class 6.1. This means that you must understand and control the hazards associated with each of the classes.

H2 Packing Groups and the Degree of Danger

Some dangerous goods are assigned to one of the three UN Packing Groups in accordance with the degree of danger they present.

- Packing Group I: Substances and preparations presenting a very severe toxicity risk

- Packing Group II: Substances and preparations presenting a serious toxicity risk

- Packing Group III: Substances and preparations presenting a relatively low toxicity risk

Class 6.1 Toxic substances are assigned to either Packing Group I, II or III, depending on their toxicity risk.

For example, lead nitrate is a Class 5.1 Oxidising agent with a subsidiary risk of Class 6.1. It is assigned to Packing Group II as it presents a serious toxicity risk during storage, handling and transport.

Safety Data Sheet: Hazards for Poisonous Chemicals

In order to control the hazards associated with these poisonous chemicals, you must first be able to correctly identify the substance – along with its hazards. To determine if your chemicals are DG Class 6 – or another class of dangerous goods altogether – refer to the current safety data sheet for each chemical product that you have onsite.

Toxic substances have a range of hazards, which can be found in the current safety data sheet for each product.

Your safety data sheets should be easily accessible and less than 5 years old in order for the information in your sheets to be current and relevant. Don’t use another product’s safety data sheet to determine the handling and storage precautions for your toxic chemicals, as every product is different. You can always request an updated safety data sheet from your supplier or chemical manufacturer.

Section 2 of a safety data sheet, titled Hazards Identification, will include information about the chemical hazards. This includes the substance’s classification, as well as the signal word/s, labelling, GHS pictograms, hazard statements, precautionary statements, and poisons schedule (SUSMP).

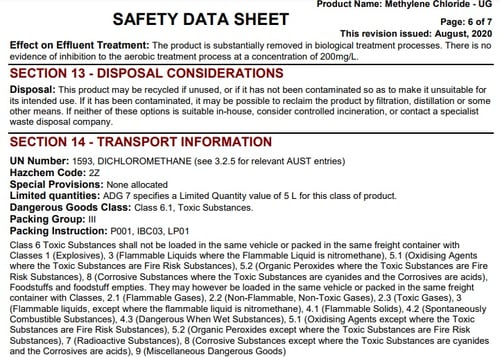

Section 14 of an SDS, titled Transport Information, contains information relevant to the transportation of the toxic substance by road, rail, marine or air. The section identifies the substance as a dangerous good in accordance with the ADG Code, and lists its transport hazards class, subsidiary risk class, compatibility with other goods, packing group, proper shipping name, and Hazchem code. This is particularly useful when determining the class of your dangerous goods for handling and storage purposes.

See Section 14 to determine the dangerous goods class of your chemical.

What is Toxicity of a Substance?

Toxicity is determined using toxicology, which is the study of the toxic effect of a particular chemical on the body. Toxicologists conduct experiments using test animals to work out how toxic a substance is, including its acute toxicity.

The information these researchers gather is used in various ways, including in the development of safety data sheets and transport regulations, such as the ADG Code.

NOTE: Information on the criteria, test methods and procedures used for the classification of dangerous goods can be found in the UN Manual of Tests and Criteria.

What Does LD50 Mean?

When referring to acute toxicity, or short-term poisoning potential, LD is short for Lethal Dose

The number after LD, or LD value, in this case 50, refers to the proportion (as a percentage) of test animals that die when given a certain amount of toxic material all at once.

So LD50 refers to the amount of material that needs to be administered to a group of test animals to cause the death of 50% or one half of that group.

What Does LC50 Mean?

LC is short for Lethal Concentration. The LC value generally refers to the concentration of a toxic material in the air, but it can also apply to the concentration of the material in water if the toxicologists were conducting an environmental study.

The OECD Guidelines for the Testing of Chemicals recommend that a traditional experiment testing acute toxicity should involve groups of test animals that are exposed to a concentration (or series of concentrations) for a set period of time, commonly four hours. However, other durations of exposure are also used, depending on the specific laws that apply to that material or research activity.

The test animals are then clinically observed for as many as fourteen days. The LC value is determined by establishing the concentration of toxic material in the air required to kill 50% of the test subjects during the observation period.

How to Interpret Toxicological Information

Acute toxicity LD values are usually expressed as the amount of toxic chemical administered to the test subject, such as milligrams per 100 grams for smaller animals, or per kilogram of body weight for bigger test subjects. Toxicologists most commonly choose rats and mice as test animals.

The route of administration or entry into the test subject’s body is generally dermal (via application to the skin) and oral (via the mouth).

Acute toxicity LC values are typically determined using the third route of entry into the body, inhalation (breathed in via the respiratory tract).

For example, the acute toxicity for methylene chloride (or dichloromethane) would be expressed as:

- Oral LD50 (rat): >2,000 mg/kg

- Dermal LD50 (rat): >2,000 mg/kg

- Inhalation LC50 (mice): 56,230 mg/m3/8hr

Based on this information about the acute toxicity of methylene chloride, an oral dose of more than 2,000 mg per kg of body weight would be acutely toxic. Skin exposure of more than 2,000 mg or breathing in more than 56,230 mg per cubic metre over an 8-hour period would also be acutely toxic.

The average male lab rat only weighs up to half a kilogram, while the average human adult male weighs considerably more (around 85 kg for the average Australian male), but the ratios remain the same for calculating what constitutes an acute effect of a toxic substance on the body.

What Other Toxicity Dose Terms are Used?

LD50 and LC50 are the two most used toxicity dose terms you will find in safety data sheets, but there are other terms used that can help provide a more thorough and accurate picture of a toxic chemical’s immediate or acute toxicity.

These toxicity dose terms include:

- LD01 - The Lethal Dose for 1% of the test subject population

- LD100 - The Lethal Dose for 100% of the test subject population

- LDLO - The lowest dose causing lethality

- TDLO - The lowest dose causing a toxic effect

Routes of Exposure

Due to the level of harm that these chemicals pose, exposure to chemical toxicity must be prevented or limited in the working environment.

Incidents such as vapour emissions from open containers, toxic chemical leaks or spills, or workplace fires involving toxic chemicals can all create hazardous conditions where serious exposure can occur.

When carrying any type of dangerous goods or hazardous chemical, a risk assessment of your site must be performed. After the completion of the risk assessment and a detailed analysis of all hazards, you can then work towards implementing a range of systems to control toxic chemical hazards in your business.

Some common control measures may include:

- Limiting or substituting the amount of toxic substances onsite

- Compliant storage practices to ensure safety

- Segregation of incompatible substances to avoid further hazards

- Separation of outdoor toxic substances stores from protected and public places

- Spill bunding to prevent uncontrolled spillage

- Handling equipment to ensure containers and packages are moved without spill incidents

- Adequate ventilation in all handling and storage areas

- Availability of up-to-date safety data sheets (SDS) at every dangerous goods store

- Creation of procedures and protocols to ensure compliant handling and storage

- Staff training and re-training to reduce likelihood of hazardous incident

- Personal protective equipment, suitable for the product, to be provided for staff – ensuring it’s fit for purpose and in good condition

- Inclusion of toxic substances and the relevant hazards within the development of emergency and evacuation procedures

- Correct dangerous goods diamond/s and hazard signage visible at all times

Compliant Class 6.1 storage is necessary to contain spills and vapours.

Controlling Even the Most Toxic Chemicals at Work

One of the most important aspects of toxic substance handling and storage, is ensuring that there is adequate ventilation for your staff. If ventilation is insufficient, your workplace may exceed the legal limits as detailed in the workplace exposure standards. This not only puts your business at risk of non-compliance, but it can harm the health of your staff, customers and other visitors to your site.

To learn more about managing the risks associated with storing and handling toxic substances, you can access our free eBook. This guide was developed to assist businesses storing toxic chemicals indoors and provides essential information on the ventilation requirements. Grab a copy of your eBook today to learn more about the requirements of the Australian Standards, limits set by the workplace exposure standards, and the installation of compliant ventilation systems in your toxic cabinets.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.