Agricultural and veterinary chemicals, also known as AgVet chemicals, consist of a variety of products designed to fulfil the following functions:

- Protect crops, livestock and domestic animals from pests and disease;

- Minimise damage to the environment by invasive pests and weeds; and

- Satisfy consumer demand for products including household insecticides, and pool and spa chemicals.

AgVet chemicals contribute long-term benefits to the Australian agricultural sector by reducing the damage done by weeds, pests and disease to our agricultural and forestry production.

The protection these chemicals provide has enabled producers to:

- Increase their productivity;

- Grow higher-quality produce;

- Reduce their environmental impact; and

- Remain competitive with imported products

This post provides a complete guide to the safe storage and handling of agricultural and veterinary chemicals in Australia by retailers and end users, including farms and rural industries.

A storage cabinet suitable for storing AgVet chemicals

Agricultural and Veterinary Chemicals in the Workplace

A wide variety of agricultural and veterinary chemicals are stored and handled in workplaces across Australia.

Common examples of agricultural chemicals in Australian workplaces include:

- Herbicides

- Fungicides

- Insecticides

- Animal Pest Baits

Common examples of veterinary medicines in Australian workplaces include:

- Parasiticides

- Vaccines

- Endocrine-related products

- Nervous, dermatological and related products

- Orals and injectables

- Anticoccidial anti-inflammatory

- Anaesthetics, analgesics and antibiotics

Some workplaces may also store and use household consumer products such as insecticides, or companion animal products such as flea and tick treatments, but in accordance with Australian WHS policy, “if an AgVet product is packaged in the same quantity as a consumer product and is likely to be used in the same manner and frequency as in a home or domestic setting then workplace labelling requirements do not apply. If the packaged quantity and concentration is not consistent with consumer use then workplace labelling requirements apply.”

How are AgVet Chemicals Regulated in Australia?

In Australia, AgVet chemical legislation, along with international and domestic policy on AgVet chemicals, is the responsibility of the Department of Agriculture and Water Resources, with support from state and territory governments and other Australian Government Departments.

The regulation of AgVet chemicals in Australia is the role of the Australian Pesticides and Veterinary Medicines Authority (APVMA), with support from other Australian Government Agencies such as the OGTR and FSANZ. The APVMA is also the independent statutory authority responsible for assessing and registering pesticides and veterinary medicines proposed for supply in Australia.

Australian Standard for the Storage and Handling of Agricultural and Veterinary Chemicals

Standards Australia developed and maintain a Standard that sets out the requirements and recommendations for the storage and handling of agricultural and veterinary chemicals, which can be classified as dangerous goods under the current Australian Dangerous Goods (ADG) Code or as scheduled poisons by the Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP or Poisons Standard).

This Standard, AS 2507:1998 The storage and handling of agricultural and veterinary chemicals, provides retailers and end user industries (including farms and rural industries) with the information required to safely store and handle packaged agricultural and veterinary chemicals, comprising:

- Dangerous goods of:

- Minor storage quantities of:

● Class 2 Aerosols (UN1950)

- Non-dangerous goods including scheduled poisons

An example of an under-bench storage cabinet for toxic substances

Industries of AgVet chemicals include:

● Pest control

● Horticulture

● Floriculture

● Recreation (including parks and gardens maintenance)

● National parks

The Standard encompasses the storage of packages, including IBCs (intermediate bulk containers) with a capacity of not more 1.6 square metres.

NOTE: This Standard does not cover the manufacture, package filling lines, transport, usage or bulk storage of AgVet chemicals. Nor does it cover the storage and handling of Class 5.1 dangerous goods (such as chlorate defoliants and ammonium nitrate fertilisers) which are covered by AS 4326.

The Standard provides advice and guidelines for:

- Minor storage of of AgVet chemicals

- Design and construction of storage areas and installations

- Operational and personnel safety

- Emergency Management

- Fire protection

- Waste disposal and decontamination

- Personnel safety

- Emergency procedures

The hazards presented by AgVet chemicals and guidelines for emergency procedures (including first aid) are covered in the Standard’s appendices.

How Agricultural and Veterinary Chemicals are Classified

Across Australia, agricultural and veterinary chemicals can be classified and identified according to two independent legislative systems:

- Medicines (or Drugs) and Poisons Schedule Classification - taking into account various attributes of the substance, including toxicity, concentration, intended use, potential for abuse, safety in use and the need for that particular substance, as outlined in the Poisons Standard (SUSMP)

- Dangerous Goods Classification - taking into account the predominant type of risk involved during land transport of that substance, as outlined under the current ADG Code

Medicines and Poisons Schedule Classification

Most agricultural and veterinary chemicals fall under Schedules 4, 5, 6 or 7 of the SUSMP (with a few that are exempt from scheduling).

When classifying pesticides, the schedule is determined according to the toxicology of their active constituent, the concentration of that constituent in the formulation and how the pesticide will be used

The type of product formulation is also considered - such as an emulsifiable concentrate, powder, granule, etc. - along with any other ingredients, especially solvents that are used during the manufacturing process.

Dangerous Goods Classification

The ADG Code assigns all transportable substances and articles to one of nine classes according to the main hazard they present. Some classes are subdivided into distinct divisions.

AgVet chemicals may be assigned to one or more classes, depending on how many hazards the substance presents.

| Example AgVet Chemicals Dangerous Goods Classification | |||||

|---|---|---|---|---|---|

| EXAMPLE A | EXAMPLE B | ||||

An AgVet liquid chemical that presents flammability and toxicity would be classified under both:

|

An AgVet solid chemical that presents toxicity and flammability (i.e., emits a flammable gas when it comes into contact with water) would be classified under:

|

||||

|

|

||||

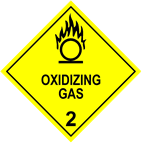

Purpose-built cabinets for storing hazardous chemicals should also display the relevant dangerous goods signage so anyone can instantly identify the hazards associated with the AgVet chemicals stored within the cabinet.

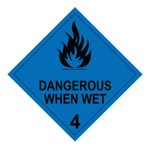

Dangerous when wet storage cabinet

What are AgVet Chemicals Labelling Requirements?

Any package containing AgVet chemicals must be labelled in accordance with the marking requirements of:

- The APVMA labelling codes

a. Including the Globally Harmonized System of Classification and Labelling (GHS)

- The ADG Code

- The SUSMP (Poisons Standard)

- Relevant State or Territory legislation

NOTE: In addition to the package labelling, dangerous goods signage and placarding should also be installed on storage facilities, unit loads and freight containers.

| AgVet Chemicals: Dangerous Goods Class Labels and Hazard Signage | |||

|---|---|---|---|

| DANGEROUS GOODS CLASS LABELS | |||

| CLASS 2: GASES (AEROSOL PRODUCTS) | |||

|

|

|

|

| CLASS 3: FLAMMABLE LIQUIDS | |||

|

|||

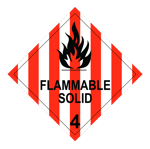

| CLASS 4.1: FLAMMABLE SOLIDS; Substances which in contact with water emit flammable gases | |||

|

.png?width=150&name=Compliant%20DG%20Signs_4%20Spontaneously%20Combustible%20(1).png) |

|

|

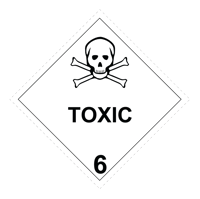

| CLASS 6.1: TOXIC SUBSTANCES | |||

|

|||

| CLASS 8: CORROSIVE SUBSTANCES | |||

|

|||

| CLASS 9: MISCELLANEOUS DANGEROUS GOODS | |||

|

|||

| HAZARD PLACARDING AND SIGNAGE | |||

|

|

|

|

|

|

|

|

What are the GHS Requirements for AgVet Chemicals?

Since January 2017, labelling AgVet chemicals has to be done in accordance with the Globally Harmonized System of Classification and Labelling (GHS).

GHS is a single, internationally agreed method of classifying chemicals and hazard communication through labelling and safety data sheets (SDS).

Hazard communication through labels and safety data sheets is one of the most effective methods for reducing the incidence of workplace accidents and minimising the potential for serious health risks caused by the improper storage and handling of AgVet chemicals.

GHS labelling and SDS combine to provide AgVet chemical product users with an immediately identifiable visual summary of the hazard (package labelling) supported by more detailed information (SDS).

This practical and easily absorbed knowledge helps people to make more informed decisions about how to handle dangerous goods and take steps to protect the health and safety of themselves, others and the environment.

NOTE: It is important that an SDS is stored securely close to the the AgVet chemicals in a purpose-built Hazmat box.

Safety Data Sheets (SDSs) should be stored securely in a Hazmat box or cabinet

What Does the Transition to GHS 7 Mean for AgVet Chemicals?

As of January 2021, Australia has entered a two-year transition to the 7th revised edition of the GHS (GHS 7).

The two-year transition period to GHS 7 will:

- Enable manufacturers and importers to develop new classifications, labels and SDSs for hazardous chemicals, including AgVet products

- Ensure Australia aligns with its key chemical trading partners, who are also adopting GHS 7

- Ensure all AgVet classifications, labelling and SDSs reflect the current system of classification and hazard communication

During the transition period, suppliers and users of hazardous AgVet chemicals can still supply and use chemicals classified and labelled under the previous edition of GHS (GHS 3). But they can’t supply or receive stock manufactured or imported after the end of 2022 if the product doesn’t have labelling or SDSs compliant with GHS 7.

Watch the Transition to GHS 7 webinar to learn about GHS 7 and its implications for chemical classification, labelling and safety data sheets.

Risks and Hazards Associated With AgVet Chemicals

Poisonous agricultural and veterinary products can enter the body through various modes of poisoning, including:

- Skin or eye contact - the most common mode of poisoning since many AgVet chemicals, such as organic pesticides, easily penetrate intact skin into the body

- Inhalation - when you inhale dust or vapour, poisoning can occur very quickly because the contaminants you breathe in enter the bloodstream through the lungs

- Ingestion - generally the least common mode of poisoning and usually caused by someone eating, drinking or smoking without washing their hands beforehand

Since the locations where AgVet chemicals are stored and used are often a long way from medical services, the severity of the hazards they present can vary depending on how quickly medical help can be administered - whether by trained professionals such as doctors and paramedics or by people on site trained in first aid. Access to antidotes and first aid kits or eyewash stations can also reduce the hazard’s severity.

Install a safety shower and eyewash station where AgVet chemicals are used

This brief video demonstrates a floor-mounted safety shower and eyewash station in action.

The symptoms of poisoning by AgVet chemicals can also vary a lot, depending on the product involved and its constituents. Maintaining appropriate and easily accessible Safety Data Sheets to facilitate users’ awareness of the hazards associated with the AgVet product being used is key to minimising the danger presented by the hazard.

How to Safely Store AgVet Chemicals

The Australian Standard for the storage and handling of agricultural and veterinary chemicals (AS 2507) outlines the criteria for minor storage of AgVet chemicals and the requirements for such storage.

To classify as minor storage, the quantities of AgVet chemicals must not exceed those outlined in the following table.

| Maximum Quantities of AgVet Chemicals Allowed as Minor Storage | |||||

|---|---|---|---|---|---|

| Location | Packing Group (PG) | Maximum Quantity | |||

| Liquids L | Solids Kg | Class 4.3 Kg* | |||

| Areas or buildings not normally associated with DG (e.g., offices, workshops, club houses), or where compliance with requirements for larger quantities is not achievable |

PG I PG II PG III & non-DG combined |

0 5 50 |

0 5 50 |

0 0 0 |

|

| Areas where packages are opened by trained personnel only (e.g., decanting, diluting, usage) |

PG I PG II PG III in packages not exceeding 210 L |

1 250 1,000 |

1 250 1,000 |

1 5 10 |

|

| Areas where packages are always kept closed and trained staff are present during operational hours (e.g., warehouses, retail premises) |

PG I PG II PG III in packages not exceeding 210 L Non-DG |

5 250 1,000 1,000 |

5 250 1,000 1,000 |

5 250 100 N/A |

|

* Indoor minor storage only

NOTES:

- All quantities are cumulative (i.e., combining maximum allowable quantities is permitted).

- While AS 2507 doesn’t cover Class 4.3 DG (dangerous when wet) above minor quantities, their presence is a factor when determining maximum quantities.

- Aerosols (UN 1950) in this instance are classified as PG III.

- Regarding Packing Groups (PG) - some dangerous goods are assigned to one of the three UN Packing Groups in accordance with the degree of danger they present:

- PG I: Substances presenting high danger

- PG II: Substances presenting medium danger

- PG III: Substances presenting low danger

Minor Storage Requirements for AgVet Chemicals

The Standard outlines the requirements for minor storage of AgVet chemicals, including:

- Construction of the minor storage area, including:

- Flooring, layout (incuding segregation from other chemicals), spillage containment (such as portable bunding), security, lighting, ventilation, and safety showers and eyewash facilities

- Separation of the minor storage area, including:

- Required distances between minor storage area and other work or storage areas (such as gas cylinders, fuel, etc.), watercourses, drains, sewers, etc.

- Requirements for fire-proof partitions

- Housekeeping, including:

- Maintaining emergency escape routes and waste management

- Handling precautions, including:

- Container management, storage, signage and labelling

- Training and hazard awareness

- Special requirements for Class 4.3 AgVet chemicals, including:

- Outdoor minor storage, including:

- Maximum quantities, area management, spill containment (such as bunding), and separation dimensions

| Maximum Quantities of AgVet Chemicals Allowed as Outdoor Minor Storage | ||

|---|---|---|

| Maximum Quantity, Kg or L | ||

| PG I | PG II | PG III |

| 10 | 500 | 3,500 |

NOTE: Class 4.3 DG (Dangerous When Wet) should not be stored outdoors.

Bunding can transform an IBC filled with AgVet chemicals into a safe and stable decanting station

Emergency Management of AgVet Chemicals

AS 2507 also sets the requirements and recommendations on planning for emergencies, the maintenance of manifests, placarding, and the management of AgVet chemical spills and leaks.

Refer to the following articles for more detailed information about emergency planning, manifests and registers of hazardous chemicals, and chemical spill management:

- Developing a chemical spill response plan

- Does your workplace need a manifest of hazardous chemicals?

- What is the difference between a Register and a Manifest of hazardous chemicals?

- How to Manage Chemical Spills: A Complete Guide

Placarding Requirements for AgVet Chemicals

In addition to the labelling and placarding requirements of the APVMA, GHS, ADG Code, Poisons Standard and relevant State or Territory legislation, the Standard stipulates that stores in which AgVet chemicals are kept must display the following:

- Appropriate dangerous goods class labels, with sides measuring at least 250mm

- A warning sign to restrict unauthorised entry

- Where applicable, a warning sign that prohibits smoking and other ignition sources, e.g., DANGER: NO SMOKING, NO IGNITION SOURCES

- Other notices or warnings required by relevant regulatory authorities - using lettering that is clearly legible from any access point and not less than 50 mm in height

NOTE: The Standard permits the use of pictograms or pictographs.

Refer to the following articles for more detailed information about placarding and labelling for AgVet chemicals:

- Mandatory signs for hazardous chemicals stored at your workplace

- GHS labelling of hazardous goods in Australia

Next Steps

Get in touch with AgVet chemical management specialists STOREMASTA to discuss:

- Conducting a risk assessment;

- Developing chemical management procedures; and

- Developing a chemical spill response plan tailored specifically to your workplace.

You can also download our FREE eBook - How to manage the risk of Hazardous Chemicals in the workplace - covering the risk assessment process, chemical hazard assessment and the implemention of control measures to eliminate or minimise the risks associated with hazardous products such as AgVet chemicals.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.