Hazardous chemical spills in the workplace have the potential to harm people, property and the environment. This guide outlines how to:

- Plan for the prevention of chemical spills, including implementing practical controls to ensure chemicals are appropriately stored and handled.

- Respond to spills when they occur, including risk assessment, spill containment, clean-up of spilled chemical, and reporting of the spill incident.

REMEMBER: Under the WHS Act, a major uncontrolled chemical spill or leakage is classed as a dangerous and notifiable incident. The regulator in your state or territory must be notified in writing as soon as possible following a chemical spill.

Who Should Use This Guide to Chemical Spill Management?

This guide applies to any workplace that stores or handles hazardous chemicals onsite. These can include flammable, corrosive or toxic liquids or compressed (pressurised) gases.

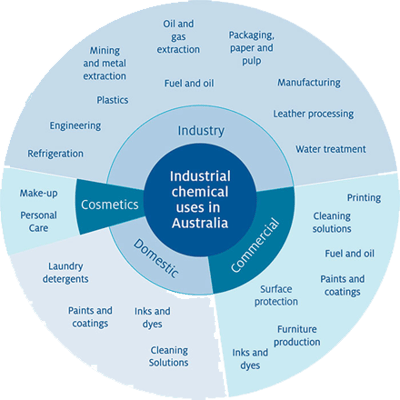

Industrial chemicals in Australia - Source: environment.gov.au

Our complete spill management guide is for people who work in industries such as:

- Chemical manufacturers storing and handling industrial chemicals

- Office buildings storing heavy-duty cleaning products

- Automotive businesses storing motor oils and fuel

- Farming businesses using and storing fuel and agricultural chemicals

- Fuel service stations storing petrol, diesel, oil and gas

- Food and beverage manufacturers producing milk products, fruit juices, etc.

- Fast food restaurants and outlets using and storing cooking oil

- Research laboratories storing and handling hazardous chemicals

REMEMBER: Personnel responsible for workplace health and safety or site management can use this resource to better understand chemical management procedures and develop a suitable chemical spill response plan.

When Do Chemical Spills Occur?

Accidents happen. But some chemical spills in the workplace are just accidents waiting to happen.

Prevention is one of the most important parts of your workplace’s chemical management program. However, even in the most well-prepared workplace environments, chemical spills and leaks can happen. This is why a tailored chemical spill response plan involving appropriate spill containment, spill kits and spill control materials is also essential for safety and compliance.

A chemical spill kit is a vital component of a chemical spill response plan

What are Contributing Factors to Chemical Spills in the Workplace?

Developing and promoting an understanding among all workplace personnel of why chemical spills happen — and what causes spill accidents to occur — is a logical way to approach chemical management.

Consider the following workplace scenarios where an avoidable minor chemical spill could occur due to various possible contributing factors.

| SPILL SCENARIO | POSSIBLE CONTRIBUTING FACTORS |

|---|---|

| A container of hazardous chemicals stacked on top of several other identical containers falls to the ground and ruptures, spilling an uncontrolled quantity of dangerous chemical that presents a significant threat to the health and safety of personnel and harm to the environment. |

|

| An uncontrolled quantity of a hazardous chemical is spilled on the workplace floor during a decanting process transferring the chemical from one container to another, endangering the health and safety of the personnel involved and potentially harming the environment. |

|

What is Bad Practice Chemical Storage and Handling?

The following images demonstrate unsafe scenarios where chemicals are being handled or stored with a high spill risk.

![]()

Source: EPA Victoria

Don’t: Keep chemical drums, IBCs and other containers on the ground, in uneven stacks or without the appropriate compliant chemical storage. To avoid leaks and spills that may affect people, property and the environment, any chemical spill risk must be managed through bunded handling or storage equipment

What is Good Practice Chemical Storage and Handling?

The following images demonstrate best practice examples of how to store and handle hazardous substances so that any leaks and chemical spills are avoided.

Source: EPA Victoria

Do: Make sure you store chemicals in bunded storage so spills and leaks can be contained. These spill containment bunds should be inspected daily, so that they may be cleaned out and kept compliant. When moving hazardous substances around the worksite, choose bunded handling equipment such as dollies or trolleys. Decanting equipment should also be utilised to reduce spill risk.

Assessing the Spill

A chemical spill is either classified as a minor or major spill, depending on various factors such as the volume spilt, the location of the spill, and how hazardous the substance is.

What is a Minor Chemical Spill?

A minor chemical spill is classified as a spill that can be effectively cleaned up by an individual person or work crew. For example, a few millilitres of cleaning chemicals are spilt when decanting into portable containers. Although the risk from industrial strength cleaning chemicals can be high, if the volume is small enough to be easily neutralised and removed, then it is considered a minor spill.

What is a Major Chemical Spill?

A major chemical spill is far more serious and generally necessitates the immediate evacuation of the area concerned, if not the entire premises. For example, the uncontrolled release of flammable liquid fuel from a container in an unventilated, enclosed area. If the volume of escaping fuel and subsequent fumes becomes large enough, the risk of ignition and harm to people and property becomes high.

Consider an incident as a major spill if the following criteria can be applied:

QUANTITY: The spill involves more than

- a) 100 millilitres or 10 grams of a highly hazardous chemical (such as a carcinogen); or

- b) 1 litre or 100 grams of a volatile or flammable solvent, reactive or corrosive (acid or base) liquid or solid.

HAZARD: The hazardous chemical

- a) presents an immediate threat to human health and safety or the environment;

- b) is unknown; or

- c) is an immediate fire hazard, such as an uncontrolled gas leak.

LOCATION: The chemical is:

- a) Outside the premises or the area where the substance is generally handled; and/or

- b) There are no suitably trained personnel available to clean up the spill

NOTE: Some especially dangerous substances, such as mercury or highly corrosive acids, are considered as major spills at volumes less than 100 millilitres.

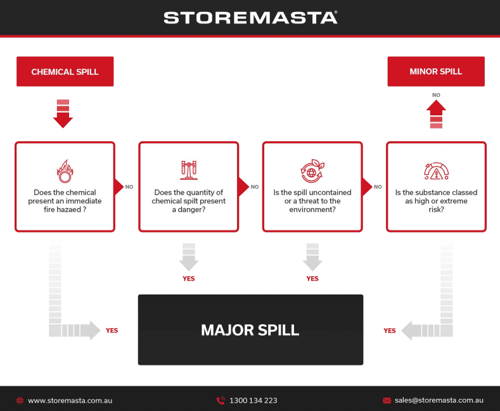

Use a Decision Tree Flowchart

The chemical spill decision tree flowchart can assist workplaces to work through the process of determining if a spill should be classed as a minor or major spill.

Through a series of questions, you can quickly navigate through the flowchart to decide whether your spill may require an in-house spill response or management from emergency services.

By determining the level of risk with your spill, you can then work towards safely and effectively containing and cleaning up the accidental release.

Spill Response

How to clean up chemical spills in the workplace is a vital question to be asked when you’re creating a spill response. While your preventative measures may be in place, it’s just as important to prepare for a potential leak or spill so you can quickly minimise risk.

Your spill response equipment, including spill kits, spill control materials (booms, pads or other chemical spill barriers) and absorbent material (wipes, pillows and floor sweep) must be suitable and compatible for the type of chemical spill that you’re dealing with.

Why a Prompt Spill Response is Essential

Responding to liquid chemical spills quickly and effectively is crucial if you are to minimise potential harm to people and the environment. Once you have determined whether the incident is a minor or major spill, you can move forward with your incident management and spill response plan.

A major spill may constitute an emergency and require urgent response and even the need for emergency services to attend the scene. A small-scale minor spill can generally be dealt with by onsite personnel. Whatever the severity of the incident, appropriate and adequate incident response is vital to ensure harm to people and the environment is minimised.

Poor incident management could, for example, lead to untrained personnel flushing spilt materials down stormwater drains, jeopardising the health of both people and the environment.

Regulators, such as the state government EPAs, recommend your incident management plan follows a response process. We’ll discuss this in detail in the next section of our post.

“Each site is different, and the issues and responses required will vary accordingly. The degree of incident planning that you need to undertake at your site will depend on the types of liquids that you store and the quantities.” EPA Victoria, Liquid storage and handling guidelines (2018)

Steps to Managing a Chemical Spill

| Contain the Spill | ||||||||

|---|---|---|---|---|---|---|---|---|

| Step 1 |

|

|||||||

| Step 2 |

|

|||||||

| Stop the Spill | ||||||||

| Step 3 |

|

|||||||

| Step 4 |

|

|||||||

| Clean-Up the Spill | ||||||||

| Step 5 |

|

|||||||

| Step 6 |

|

|||||||

| Step 7 |

|

|||||||

| Report the Spill | ||||||||

| Step 8 |

|

|||||||

Chemical Spills in the Workplace

By conducting a risk assessment, developing chemical management procedures, and creating a chemical spill response plan specifically tailored to your workplace, you can reduce the likelihood and impact of chemical spills.

To learn more about chemical spill management and prevent, why not access our eBook? How to manage the risk of Hazardous Chemicals in the workplace highlights the risk assessment process — explaining how to assess each chemical hazard you encounter at work and how to decide on suitable control measures to eliminate or minimise the risk. Grab your copy for free today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.