What are the spill kit regulations in Australia — and how does that apply to your workplace? In this blog, we answer your questions about the installation of spill kits in areas of your business that may be prone to chemical spills. By understanding the Work Health and Safety Regulations — and accessing other useful resources — you can better prepare for the clean-up and management of a hazardous chemical leak or spill.

Let’s begin by looking at the basic regulations that relate to chemical spillage in the workplace.

What Regulations Apply to Chemical Spills?

While the WHS Regulations offer broad guidance on your legal obligations for workplace health and safety matters (including hazardous chemical spills), there are also a range of resources to help you understand your spill kit obligations. We’ll go into detail about these Codes of Practice and Australian Standards a little later in the blog.

IMPORTANT: We strongly recommend conducting an onsite risk assessment to determine your chemical handling, storage and spillage management needs. If your staff are not able to perform a risk assessment themselves, enlist the assistance of a Dangerous Goods Specialist or Consultant who can accurately determine the hazards present.

In regard to the WHS Regulations, the national policy explains in Section 357 of Subdivision 2 Spills and damage your legal obligations in relation to hazardous chemical spills. We’ll look at these in detail below.

Understanding the regulations that apply to chemical spills will help you maintain compliance and safety.

Containing and Managing a Hazardous Chemical Spill

Under WHS Law, any person who is conducting a business or undertaking at a workplace must make provision for the containment and management of spills. As far as is reasonably practicable, provisions for containment and management must be present in every area where a hazardous chemical is used, handled, generated or stored.

Your duty of care includes the safe containment and management of hazardous chemical leaks and spills, as well as any resulting effluent.

Failure to provide these measures may result in a $6000 maximum penalty for an individual.

Ensuring There are No New Hazards Created During Containment

You are also obliged to ensure that the spill containment system does not result in additional chemical hazards due to the incompatibility of different hazardous chemicals.

Failure to follow this regulation can cost up to $6000 in a penalty.

Defining Compatible Substances, Items and Mixtures

The Regulations explains that ‘compatible’ refers to two or more substances, items or mixtures that do not react with each other to cause a chemical safety incident. Such incidents can include fire, explosion, a harmful reaction of the evolution of flammable, toxic or corrosive vapours.

Incompatible substances must not be brought together during the spill clean-up, as it could result in risks such as fire or explosion.

Clean-Up and Disposal System

Part 3 of this Section specifically applies to your spill kit clean-up procedures, as well as your hazardous chemical waste disposal system. The WHS Regulation explains that your containment system must provide for the successful clean-up and disposal of hazardous chemicals – as well as the resulting effluent.

Failure to do so can cost individuals up to $6000 for non-compliance.

Other Helpful Resources

While the WHS Regulations outline the obligation of individuals to ensure that hazardous chemical spills are contained and managed, there are additional resources that can assist with understanding your spill kit requirements.

Your Safety Data Sheets

If you’re a frequent reader of our blogs, you will understand how important it is to refer to (and have freely available to staff) your Safety Data Sheets (SDS). Your SDS will explain the precautions, PPE and emergency procedures required for the accidental release of your hazardous chemicals.

Your SDS should be located in a highly visible and easily accessible position, so staff can refer to it in the event of a chemical spill.

Understanding the hazards that your chemicals pose to people, property and the environment, will help you develop a compliant spill containment and management plan. Your SDS should also include specific instructions that relate to the clean-up of small and large chemical spills.

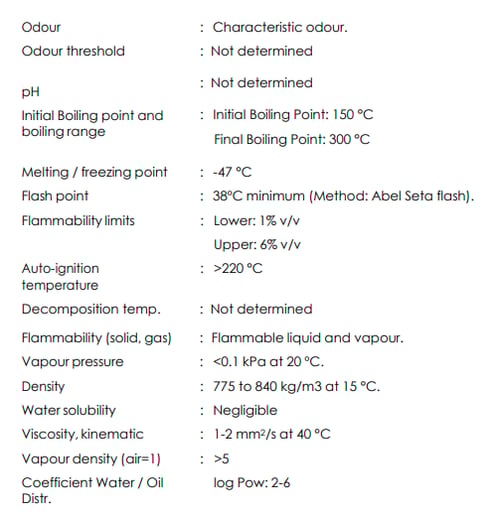

Some specific points of interest in your SDS may include:

- The provision for specific PPE (ie respiratory protective equipment, chemical resistant boots and protective suits)

- Risk control measures to take (ie the evacuation of surrounding areas, the isolation of ignition sources, the provision of adequate ventilation, the slipperiness of floors)

- The containment of spilt substances as well as runoff (so the chemical spill does not enter soil, drains, sewers or waterways)

- Using spark-proof tools and explosion-proof equipment (for flammable liquid spills)

- Choosing the correct absorbent materials suitable for the particular chemical (ie absorbent pads, sand, earth etc)

- The correct method of disposal (ie placing soiled materials in sealed containers and waste bags, as well as using disposal methods that adhere to local regulations)

REMEMBER: Use the detailed guidance in your individual SDS to form the basis of your Spill Response Plan. Your plan should also include relevant information about who is responsible for the clean-up of a chemical spill, as well as how to use the onsite spill kits.

The Relevant Australian Standards

When you’re using any type of dangerous goods in the workplace, you should always refer to the Australian Standards. These guides are particularly helpful when it comes to hazardous chemical spillage, offering a wealth of information regarding spillage control measures, as well as the spill clean-up and disposal process.

Hazardous chemical spills, regardless of the class of chemical that you’re using, must be contained and managed as soon as the incident occurs. For small leaks and spill, the clean-up process can usually be handled by your staff — as long as they are provided with the appropriate equipment, have received the correct hazardous chemical spill training, are following procedures, and have constant supervision during the clean-up process.

The relevant Australian Standard will provide you with information to both prevent and manage spillage in the workplace.

General requirements will include details on:

- Chemical hazard identification

- Safe handling procedures

- Correct PPE, as well as the method of use, care and maintenance

- Hazard control measures that are to be in place

- Location of fire protection equipment and emergency contacts

- Location of first aid equipment and first aid measures

- Emergency procedures to follow if there is spillage

IMPORTANT: Larger spills, that cannot be contained by your organisation, require the immediate notification of emergency services, the evacuation of premises and contact with the relevant regulatory authorities. You should refer to your Spill Response Plan and Emergency Plan to determine the correct actions that should be taken in the event of a major chemical spill.

Code of Practice

In Safe Work Australia’s Code of Practice, Managing Risks Of Hazardous Chemicals In The Workplace, we find useful information about the prevention and management of spillage.

While engineering controls are crucial for the prevention of chemical spills, it is also important to consider developing the correct administrative controls.

This Code of Practice also offers helpful advice on the administrative controls required for hazardous chemicals.

These controls include:

- Cleaning up hazardous chemical spill immediately

- The provision for PPE which is suitable in size and fit, applicable for the nature of work, and maintained, repaired or replaced so it continues to minimise chemical risk

- The provision of washing facilities so chemicals can be rinsed off the skin or eyes of workers

- Written policies and work procedures to reduce risk

- Safe work practices including the cleaning and housekeeping of hazardous chemical work areas

The Code of Practice goes on to explain that immediate and appropriate actions must be taken when a leak, spill or accidental release of hazardous chemicals occurs. The containment system must describe the containment, clean-up and disposal of the leak or spill, plus any resulting effluent.

You’re obliged to immediately clean-up a chemical spill or leak and dispose the chemicals and effluent in a safe manner.

The spill containment system should not bring together incompatible chemicals, as this will create further hazards during the clean-up and disposal process.

This Code of Practice also highlights the fact that open containers are one of the main causes of hazardous chemical spillage. Therefore, chemical containers must be kept tightly closed when not in use to reduce spillage risk. Procedures, training and supervision of staff should also be used to control the risk.

Considerations which can affect your choice of spill kits, as well as the spill containment system in general, may include:

- Quantity and nature of hazardous chemicals

- Size of largest container, or the largest foreseeable chemical spill

- The potential impact if chemicals escaped into the environment

- Materials used for absorption of the spillage, or used with the containment system, must be compatible with the hazardous chemical

- Maintenance of the spill containment system (including spill kits) must be ongoing

Understanding Your Spill Kit Obligations

As we’ve explained in this blog, there are a valuable range of resources that are available to help you develop and maintain an effective spill containment system. Choosing the right engineering controls and implementing strict administrative controls, are just two steps that are important when striving to prevent hazardous chemical spillage. When determining your spill kit requirements and spill response, make sure you’re creating a clean-up and disposal system that has the right equipment, training and procedures to properly protect your business.

If you’d like to learn more about controlling the risks associated with hazardous chemical leaks and spills, why not download our easy-to-read guide? How To Manage The Risk Of Hazardous Chemicals In The Workplace offers expert advice and detailed guidance on how you can quickly reduce incidents such as hazardous chemical spillage in your workplace. Access your free copy of our guide now by simply clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.