Whatever industry you’re in, whether it’s mining, manufacturing, agriculture or defence, your operations likely depend on fuel to power equipment, machinery and vehicles. However, when you’re carrying stores of petrol and fuel you must also be aware of how to successfully contain and manage fuel spills in the workplace. Petrol and diesel, two commonly used hydrocarbon products, can create a range of hazards if they spill or leak into work areas. In this blog, we’ll be highlighting some key points for consideration when you’re preparing a Spill Response Plan for your business. We’ll also be offering advice on how to minimise the risk of ignition, human harm and environmental contamination during the spill containment and management process.

IMPORTANT: Your organisation should develop a Spill Response Plan after a risk assessment has been conducted at your site. It may be developed in conjunction with local emergency services. Your plan should also include the provision of staff training, chemical spill simulations and emergency evacuation drills.

What Are The Properties Of Fuel?

Petrol and diesel are fuel products which can be manufactured from petroleum (a mixture of crude oil and natural gases). They are known as ‘hydrocarbon fuels’ because they are a product that is derived from a hydrocarbon. As an organic compound that consists of hydrogen and carbon, hydrocarbons pose hazards to the organisations that use them due to their flammable or combustible nature.

Regardless of the fuel that you’re using in your workplace, the one thing that all petroleum-based fuels have in common is that they are recognised as Class 3 Flammable and Combustible Liquids for the purposes of storage.

DID YOU KNOW? While diesel is recognised as a Class 3 liquid for storage purposes, it’s not classed as a dangerous substance for transport by the Australian Dangerous Goods Code (ADGC). Most diesel fuels are recognised as C1 combustibles as their flash point is normally above 60 °C.

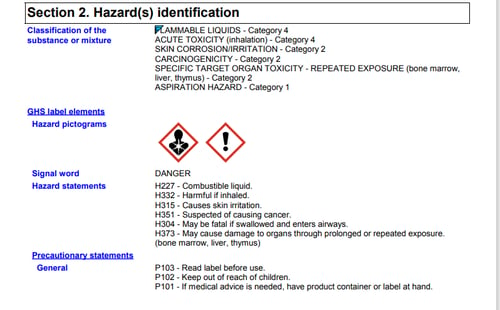

Your Safety Data Sheet will help you determine the risks associated with your fuel, as well as how to deal with an accidental release.

What Hazards Does Fuel Pose?

To understand how to properly manage a fuel spill or leak in the workplace, we must first understand the specific risks associated with fuel products such as petrol and diesel. We’ll go into detail about some of these key risks below:

Ignition

For petrol and diesel, the flash point of the chemical is the determining property which defines if the chemical is flammable or combustible.

REMEMBER: Flash points are used to determine the flammability or combustibility of a substance. The flash point is defined as the minimum temperature that a liquid emits sufficient flammable vapours to ignite in the presence of an ignition source.

Generally, petrol has a lower flash point than most types of diesel – which means petrol has the ability to cause a fire or explosion in relatively low temperatures (below 60 °C). Therefore, petrol is regarded as a flammable liquid.

Many types of diesel, on the other hand, have a higher flash point. This means that they are classed as combustible liquids; requiring slightly warmer conditions in which to produce enough hazardous vapours to ignite in the presence of a workplace ignition source. Combustible liquids may not be as volatile as flammable liquids, but they still require careful handling and storage (even during the spill clean-up process) to reduce the risk of ignition.

Controlling ignition sources within the work area is critical to maintaining safety during an accidental release of petrol or diesel.

While many diesel products are classed as combustible substances, others may have a lower flash point and be regarded as flammable. Therefore, you must refer to the individual SDS of the fuel product that you’re storing to see the exact flash point of your substance to determine the risks associated with your product.

Human Harm

The physical and chemical properties of fuel also add further complications to the spill containment and management process.

Fuel poses a range of health hazards for workers who are exposed to the liquid — and the resulting vapours.

If fuel is splashed onto the skin or into the eyes of staff, it will cause skin irritations and eye damage. Fuel also produces hazardous vapours which must not be inhaled by workers. Inhalation can result in dizziness and respiratory problems, as well as posing an asphyxiation risk.

Repeated exposure to many types of fuel can also result in chronic health issues, such as cancer. Your SDS will inform you if the fuel is a carcinogenic — and the steps to take to reduce the likelihood and impact of repeated exposure to your workers.

Due to the viscous and oily nature of fuel, it can also cause a slip hazard for the workers that are cleaning up the leak or spill. Therefore, only trained and authorised personnel — dressed in the correct protective equipment and footwear — should be allowed to enter the spill site and manage the clean-up process.

Environmental Damage

The accidental release of fuel must be managed in such a way that prevents contamination of the natural environment. Organisations must have spill containment plan that effectively stops the leak or spill from spreading throughout the workplace, well as prohibiting the substance from entering soil, waterways, drains or sewers.

Fuel must be prohibited from entering the natural environment through any drainage and sewage systems.

Due to the oily, viscous properties of fuel, spills can quickly travel through work areas and threaten the safety of workers. However, fuel can also quickly spill into the outdoors or enter drainage or sewer systems. This can lead to the contamination of soil and water, as well as the poisoning of farm animals, aquatic animals or wildlife.

Reducing Risks Associated With Fuel Spills

To reduce these risks, great care must be taken when dealing with a fuel spill in the workplace to avoid:

- Ignition sources – isolate/shut down all types of ignition sources, such as electrical devices, open flames, hot surfaces and heat.

- Exposure – workers must be dressed in PPE to avoid any contact with the skin and eyes.

- Inhalation – in the event of a chemical spill, you must provide as much natural or mechanical ventilation as possible to dissipate flammable and hazardous vapours. Workers tending to the spill must wear the appropriate breathing apparatus.

- Environmental contamination – accidental releases of fuel must not contaminate waterways or soil as fuel poses hazards to both animal and aquatic life, as well as the natural environment itself.

IMPORTANT: When dealing with a fuel spill in your workplace, you need to have a Spill Response Plan in place that specifically reduces the risks associated with the product. If a new chemical or fuel is brought onsite, then a further risk assessment must be conducted to ensure that all hazards (and chemical incompatibilities) are accurately addressed and managed.

Step 1: Containment

Whether you’re dealing with a jerry can being knocked over in a workshop or a toppled fuel drum in a storeroom, it’s vital that spillage is contained in the most effective and timely manner possible. When dealing with a chemical spill, the first step is to ensure that the right people are notified of the spill (management, trained personnel responsible for the spill clean-up, and emergency services, if required). The next step is to ensure that the area is securely cordoned off so that staff and contractors can’t enter the site.

If you have secondary containment measures in your work area, such as floor bunding, bunded drum dollies or bunded storage cabinets, the spill may not be able to spread so easily throughout your workplace. You may be able to quickly contain your fuel spillage by simply laying down a single mini boom around the spill.

However, if the spill is greater in quantity — or there is no secondary containment system in place — you should immediately place down multiple booms to prohibit the spread of the flammable or combustible substance through the work area.

Make sure that any open drains are plugged to prevent the fuel from entering waterways and sewers. If the substance can reach other work areas, or the outdoors, immediately place booms or containment systems to stop the liquid from reaching these areas.

Step 2: Clean-Up

When dealing with an accidental release of petrol or diesel, you must have the right clean-up equipment. Oil and fuel spill kits, otherwise known as hydrocarbon spill kits, are specifically designed for use with fuel leaks and spills. They are also suitable for the clean-up of other substances including plant and seed oils, petroleum-based solvents and petrochemicals.

These type of spill kits offer compatible materials which won’t create further risks during the spill containment and clean-up process. Due to the risk of ignition, you must ensure that the absorbent materials that you use don’t create static electricity. Static can cause flammable vapours to spark and cause a fire or explosion.

The hydrocarbon kit is also specifically designed to deal with the oily nature of the chemical. Absorbent pads can repel water and float, which is ideal for cleaning up petrol or diesel spills.

Your spill kit may also include a floor sweep which can be laid over the spill for fast and accurate absorbency. Floor sweeps can generally absorb up to three time their own weight in liquid chemicals.

Your absorbent materials, such as absorbent pads and floor sweeps, should be compatible with the substances that you’re cleaning up.

Step 3: Disposal

Once the fuel spill has been mopped up by your team, it’s time to decontaminate the site and dispose of the chemical waste.

Place all spilled chemicals in containers with lids and place in the waste disposal bags. Gather up all soiled booms, absorbents, floor sweep and other materials used for the clean-up and place these in additional waste bags.

Ensure that staff safey remove a ll PPE and follow the correct procedures for the equipment’s disposal or cleaning. Never placed used clothing or equipment back in a PPE storage cabinet as the chemical residue will still be present on the items. PPE must be laundered or disposed of to reduce the risk of human harm and ignition.

As flammable and combustible liquids can still pose an ignition risk during the disposal process, you must ensure that compliant waste disposal procedures are followed in the event of a chemical spill.

Step 4: Reporting

After the spill has been cleaned-up, with the chemicals and waste carefully removed, it’s time to report the spillage incident.

Reporting allows your business to keep accurate records of workplace health and safety incidents. It also allows your team to review the situation that caused the spill and implement measures to reduce the risk of the incident happening again.

Safely Managing Fuel Spills

Through the development of a Spill Response Plan, the training of staff and the acquisition of the correct spill containment and clean-up equipment, you can safely manage fuel spills and leaks in the workplace. However, the best way to minimise risk in your organisation is to ensure that flammable and combustible liquids, such as fuel, are handled and stored in a way that reduces the likelihood and impact of chemical spills.

To find out more about improving the safety of your operations, why not download our helpful guide? Essential Considerations When Storing Flammable Liquids Indoors will help you protect your organisation from incidents such as fuel spills and leaks. Access your copy of our free guide today to learn more about the containment of Class 3 liquid spills.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.