Here at Storemasta, we’re serious about our role in helping workplaces reduce the risk of illness and injury to their workers (as well as comply with Australian WHS laws). And to do this we’ve developed a clear methodology for carrying out risk management on hazardous chemicals.

We know that a lot of our clients as well as other business owners and operators often feel overwhelmed by the term ‘Risk Management’. Especially when they have to relate it to every hazardous substance used at their workplace. This blog will introduce you to our clear methodology and walk you through the 4 essential steps in reducing the risk of someone being harmed by the chemicals on your worksite.

Step 1: Identify

The first (and in some ways the most critical) step in chemical management is to find out exactly what you are dealing with. So you’ll need to identify every single substance that’s being used or stored at your work-site, plus the hazards associated with using it.

You can do this by conducting a full site check and ideally a walk-around to physically identify each substance. At large, complex worksites this can be a challenging procedure and you will probably need the assistance of departmental managers, floor supervisors and line staff. A sitemap and floor plan will also be essential.

Your initial list might look something like this …

|

Chemical |

Location |

Notes |

|

Petrol |

Drums of petrol near the weighbridge. |

Truck drivers bringing raw materials smoking inside their vehicles. |

|

Toluene |

Waste processing area. |

Discarded rags soaked in toluene thrown into the general waste. |

Once you’ve identified all the substances obtain the Safety Data Sheet (SDS) for each of them, you should note the hazard class of every substance as well any environmental concerns. The hazard class identifies whether the substance is known to be:

- flammable

- explosive

- self-reactive

- corrosive

- toxic

- carcinogenic

REMEMBER: there are hazards associated with the disposal of chemicals; make sure your site inspection doesn’t overlook waste processing areas and individual work stations.

Step 2: Assess

Now you have your master list of chemicals and an SDS for each of them you can begin the risk assessment. Your risk assessment will look at the each of the hazards associated with the chemical, concerns about work practices, hazardous events that could occur, how often those events might occur, and the possible outcomes.

Your risk assessment might begin like this:

|

Substance |

Petrol |

|

Hazards |

|

|

Location |

|

|

Concerns |

|

|

Hazardous Events |

|

|

Possible Frequency |

|

|

Likely Outcomes |

|

Once you’ve identified the severity of the risk you can begin prioritising an action plan to control the risks associated with each and every chemical.

REMEMBER: Storemasta's Chemical Management Procedure provides a clear formula for assessing the risk associated with a hazardous substance. To learn more download our free eBook:

Step 3: Control

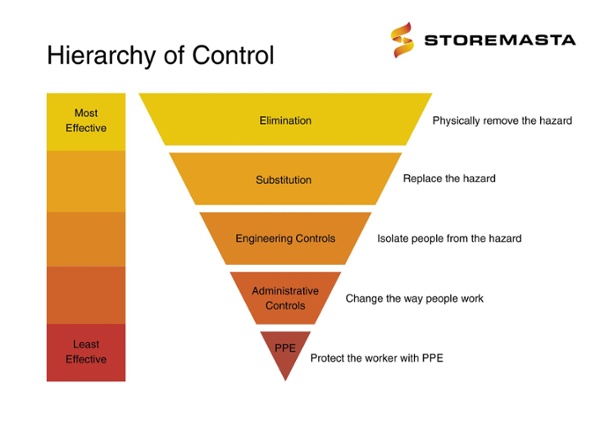

Now it’s time to take action to control the risks associated with each of the chemicals. There are 5 different approaches you must apply to each chemical and they are numbered in order below. This is also known as the Hierarchy of Control.

- Elimination (could you stop using the chemical?)

- Substitution (could you use another chemicals that is less harmful?)

- Engineering controls (could you design the workplace to reduce the amount of employees who are exposed to the chemical?)

- Administrative controls (can you implement safe work methods?)

- Personal Protective equipment (what protective equipment can be used to protect workers?)

Using the example of the petrol stored in drums near a fire hose and adjacent protected wetlands. An engineering control to move the drums to another area might eliminate the environmental damage to the wetlands and the chance a firefighter might use water on a petrol fire.

REMEMBER: Eliminating the hazard completely is always the best control measure. Always try to do this first before working your way through the Hierarchy of Control.

Step 4: Sustain

Now you’ve implemented the control measures (like moving those drums of petrol to another area or taking them offsite completely) you need to sustain your efforts by making sure that:

- no new hazards have been created through your control measures

- changes to the SDS or worksite are assessed

- new chemicals introduced to the workplace are controlled

The Storemasta Chemical Management Procedure helps you develop a system to regularly audit the WHS control measures and test your overall compliance to legislation. A half yearly or annual external assessment would be recommended to ensure that your storage systems and facilities comply with the dangerous goods standards and regulations.

Storemasta Chemical Risk Management

This blog has been an introduction to the Storemasta Chemical Management Procedure. We recommend that you now download and our FREE eBook How to manage the risk of Hazardous Chemicals in the workplace. The eBook walks you through our chemical management procedure and contains useful templates and actionable tools. If you are serious about chemical safety at work, download your free copy today to learn more.

Talarah has been working for Storemasta for many years, specialising in Marketing, Customer Service and Risk Management Solutions.