How is your business handling its HAZCHEM storage requirements? While countless workplaces carry a range of flammable liquids, corrosives and toxic chemicals, it’s important to remember that these commonly found chemicals do require safe and compliant storage. Failure to do so can result in serious incidences such as fires, explosions and chemical reactions. In this blog, we’re taking a deeper dive into HAZCHEM storage by highlighting the key requirements for storing each of these hazard classes safely — and in accordance with Australian Standards.

Understanding Chemical Types

To store hazardous chemicals legally and safely, it’s critically important to understand the chemical properties of each substance — as well as their physical and health hazards. We recommend carrying out a risk assessment that refers to the Safety Data Sheets (SDS) and industry guidelines. Your risk assessment will help you accurately identify risks at your worksite, so you can implement the right control measures to protect your staff, property, community and environment.

To help you determine the risks that you may face due to your stores of hazardous chemicals, we’ll now explain the dangerous properties of flammable liquids, corrosives and toxic chemicals.

REMEMBER: The first step in safe HAZCHEM storage is to carry out a risk assessment based on information from the SDS of each chemical, as well as the requirements of the Australian Standards.

Flammable and Combustible Liquids

Flammable and combustible liquids are some of the most common substances found on worksites.

Class 3 Dangerous Goods includes a broad range of every day products including:

- petrol

- diesel fuel

- ethanol

- methanol

- toluene

- methyl benzine

- degreasers

- kerosene

- turpentine

- fuel oils

- lubricants

- adhesives

- resins

- enamel paints

- pesticides

- insecticides

Flammable liquids are found in many workplaces and include common products including enamel paint, resins, fuel and lubricants.

Flammable liquids can be harmful to human health if inhaled, swallowed, ingested, or splashed onto the skin and eyes. Depending on the properties of the individual chemicals, they can cause nausea, vomiting, dizziness, impairment, respiratory complications, asthma and dermatitis.

Some flammable liquids are also carcinogenic. This means that these flammable liquids can cause chronic disease and cancer with repeated, long-term exposure.

Because flammable liquids are so common and widely used, workers may tend to downgrade their safety risks and hazards. However, don’t be fooled: These chemicals pose the risk of fire, explosion and human harm. Flammable liquids must be isolated from ignition sources, as they can easily ignite at room temperature. These chemicals can also auto-ignite or explode at a higher temperature.

Make sure your stores of flammable liquids are isolated from ignition sources such as power points, naked flames and hot surfaces.

You must also be careful to store your flammable liquids apart from incompatible substances, as a chemical reaction can occur. Flammable liquids must be segregated from incompatible substances by either 3 metres or 5 metres — depending on the Dangerous Goods class of the chemical.

Corrosives

Corrosives are also a common sight in workplaces, with this class of Dangerous Goods often used as a cleaning agent or degreaser.

Some different types of Class 8 Corrosives include:

- sulphuric acid

- hydrochloric acid

- acetic acid

- nitric acid

- hydrofluoric acid

- bromine

- caustic soda (sodium hydroxide)

- ammonium hydroxide

- potassium hydroxide

- hydrogen peroxide

Corrosives are recognised for their ability to rapidly deteriorate a range of surfaces — including human skin. If corrosives are not diligently stored and handled in a manner that reduces risk, they can seriously harm the people, property and environment of your organisation.

Corrosives can attack living tissue and some metals, and can cause harm to staff, vehicles, property and the natural environment.

The class of Dangerous Goods can chemically attack and destroy living tissue — and therefore must be handled with extreme care.

If corrosive chemicals are inhaled by workers, it can result in burns to the respiratory tract which can cause pulmonary edema — and even death. When corrosives are splashed onto the eyes or skin, the chemical will immediately cause damage to the tissue. This can result in workers suffering from blisters, burns, eye damage or blindness. If Class 8 chemicals are accidently swallowed, they will burn the throat and digestive system, causing serious human harm or fatalities.

In addition to these substantial risks, corrosives can also cause harm to the natural environment. If the chemical enters the waterways, it can pollute the water — causing death or harm to wildlife and aquatic life.

Corrosives also present a unique storage hazard. As this hazardous chemical can destroy some metals, they must be isolated from incompatible containers and storage materials. For this reason, corrosives are usually kept inside containers and chemical storage cabinets that are made from polyethylene.

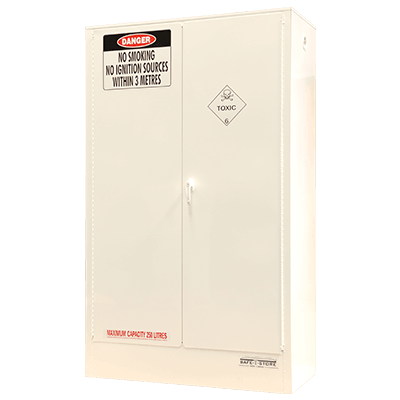

Your stores of corrosives must be kept in corrosion resistant storage containers and cabinets that are not susceptible to chemical attack, such as this poly cabinet.

Toxic Chemicals

Toxic chemicals are the poisons and substances that are harmful to humans and living things.

Class 6.1 Toxic Substances include a range of products such as:

- pesticides

- herbicides

- cyanide

- formaldehyde

- acrylonitrile

- hydrogen sulfide

- mercury

- lead arsenic

- strychnine

Toxic chemicals can cause both acute and chronic poisoning — which develops with repeated exposure to the chemical. The severity of the poisoning depends on several factors including the:

- Toxicity of the chemical

- Route of exposure (swallowing, inhalation, ingestion, absorption)

- Chemical concentration

- Overall health factors of the person

You must ensure that toxic chemicals are segregated from incompatible chemicals, as they can release toxic gases and fumes.

Due to the serious risks that they pose to both human health and the environment, toxic chemicals must be stored in a careful and compliant manner. Toxic substances will react in the presence of other chemicals, as well as heat and fire. There is the potential that the chemical will create deadly fumes and toxic gases if they’re not handled and stored in the right way. When carrying toxic chemicals in your workplace, you must pay attention to individual compatibility hazards.

What Are The Compatibility Hazards?

When storing hazardous chemical or dangerous goods it’s very important to be aware of the chemical’s compatibility hazards. Check the Safety Data Sheet (SDS) for specific storage recommendations. Section 7: Handling and storage and Section 10: stability and reactivity are the sections within the SDS that contain the required information.

Flammable liquids, corrosives and toxic chemicals are all different classes of Dangerous Goods and are therefore subject to the segregation requirements of Australian Standard AS3833:2007 — The storage and handling of mixed classes of dangerous goods, in packages and intermediate bulk containers.

These hazardous substances must be segregated from each other as follows:

- Class 3 Flammable Liquids - must be segregated by a distance of at least 3 metres from Class 6 Toxic Substances and/or Class 8 Corrosive Substances.

- Class 6 Toxic Substances – must be segregated by a distance of at least 3 metres from Class 3 Flammable Liquids. Check the individual SDS of your toxic substances to determine the segregation distance when storing near Class 8 Corrosive Substances.

- Class 8 Corrosive Substances – must be segregated by a distance of at least 3 metres from Class 3 Flammable Liquids. Check the individual SDS of your toxic substances to determine the segregation distance when storing near Class 6 Toxic Substances. You must also consult the SDS when storing Class 8 Dangerous Goods of the same class as they may react with each other or be incompatible.

If you are storing further classes of Dangerous Goods in your workplace, you must refer to the DG segregation chart to ensure that all chemicals in your workplace are isolated from incompatible chemicals. Consult the SDS for each chemical that you’re carrying to determine the exact segregation requirements.

REMEMBER: Using compliant indoor safety cabinets for each hazard class may negate the need for separation distances between cabinets. This is particularly useful is smaller workplaces or areas where it’s not practical to maintain the chemical segregation distances.

Reducing HAZCHEM Risk With Indoor Safety Cabinets

One of the best ways to minimise your HAZCHEM risk is to store drums, bottles and containers of flammable liquids, corrosives and toxic chemicals inside dedicated indoor safety cabinets.

The key benefits of using an indoor safety cabinet for your flammable liquids, corrosives and toxic chemicals is because they:

- Offer liquid-tight spill protection for the chemicals

- Safely contain vapours and fumes

- Reduce segregation distance requirements

Because the chemicals are fully contained within the cabinets, the segregation distances we outlined in the last section can be reduced (provided the cabinets are loaded and used correctly).

Storing Flammable Liquids

Safety cabinets for storing flammable and combustible liquids have the following requirements:

- Constructed from double-walled sheet steel.

- Construction materials and componentry must be able to withstand temperatures of up to 850 °C.

- Have self-closing doors, self-latching doors that latch at least two points.

- If the cabinet doors use mechanisms to keep them open, these must automatically release if temperature exceeds a nominal 80°C.

ESSENTIAL REFERENCE: AS 1940 - The storage and handling of flammable and combustible liquids

Storing Corrosives

Safety cabinets for storing corrosive substances are constructed to meet the following requirements:

- Constructed from materials that are resistant to corrosion or have a corrosion resistant protective coating.

- Cabinet doors must be self-closing and create a seal that contains corrosive vapours.

- Cabinet doors must not open inwards.

- Cabinet doors must be able to be opened from inside the cabinet.

- Cabinets must be located near hand washing facilities.

ESSENTIAL REFERENCE: AS 3780 — The storage and handling of corrosive substances

Storing Toxic Substances

Toxic substance safety cabinets have the following requirements to reduce risk:

- Double-walled sheet steel construction that can withstand temperatures of at least 850 °C.

- Close fitting doors that close automatically.

- Cabinets must be lockable.

- If fumes cannot be fully contained within the cabinet, a mechanical ventilation must be fitted to the cabinet.

Store toxic substances in a cabinet that’s been designed and manufactured in full conformance with AS 4452:1997

ESSENTIAL REFERENCE: AS 4452 — The storage and handling of toxic substances

How Safe Is Your HAZCHEM Storage?

Thanks for taking the time to read our blog about HAZCHEM storage for flammable liquids, corrosives and toxic chemicals. As we’ve discussed, there are a range of risks associated with storing each class of Dangerous Goods — with the risk increasing when there are multiple DG classes stored onsite. By following the requirements of the Australian Standards, you’ll be taking the right steps towards reducing chemical risk. If you’d like to learn more about HAZCHEM safety, why not download our helpful guide? Essential Considerations When Storing Flammable Liquids Indoors will help you assess your chemical compliance risk and ensure your flammable liquids storage cabinet meets all the requirements of AS1940:2017 – The storage and handling of flammable and combustible liquids. Download our free guide and read it today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.