When you identify a chemical hazard at your job site, you should ideally aim to eliminate the hazard completely. However, in many cases, eliminate just isn’t possible. This is because the hazardous chemical is usually fundamental to the way you do business or is required for the production of goods. Therefore, many businesses must consider the benefits of eliminating vs substituting chemical hazards.

In this post, we’ll be walking you through the Hierarchy of Control to help you better understand this process. We’ll also be focusing on the steps to take when eliminating or substituting a chemical hazard in your workplace.

DEFINITION: ’Elimination’ means removing a hazard or hazardous work practice from the workplace. This is the most effective control measure and must always be considered before other control measures. - SAFE WORK AUSTRALIA

Understanding the Hierarchy of Control For Chemical Hazards

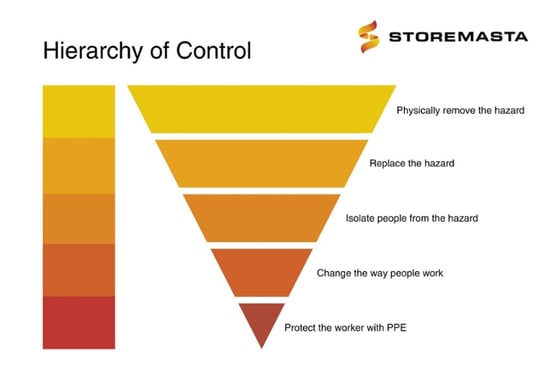

The Hierarchy of Control is an important method for deciding the best way to eliminate or minimise the risks surrounding hazardous chemicals in the workplace.

The Hierarchy of Control categorises different types of hazard control measures into groups — and then ranks them based on how effective they are.

Elimination is considered the most effective chemical hazard control within the Hierarchy of Control.

The control measures that are the most reliable and effective are given the highest ranking. The Hierarchy of Controls details the steps to hazard control as follows:

- Elimination – The first step in the Hierarchy of Control is the most effective control measure. The process of hazard elimination is about completely removing the chemical hazard from your workplace. To achieve this, you must eliminate the need for a specific chemical or eliminate the hazardous job task itself.

- Substitution – Hazard substitution involves finding another less hazardous chemical to use in your business. You may also substitute the chemical hazard by developing a safer way to complete the job task.

- Engineering – Engineering controls may include the installation of a mechanical device or machine that can isolate people from the chemical. The engineering control may make the job task safer, thereby decreasing the risk posed by the chemical hazard.

- Administration – Workplaces can improve chemical safety onsite by implementing administrative controls. These administrative controls may include the development of safe work methods and improved operating procedures.

- Personal Protective Equipment (PPE) - Have workers and contractors wear and use PPE. However, understand that personal protective equipment is the least effective control and must only be used as a final protective measure when dealing with chemical hazards.

You should apply the Hierarchy of Control to every chemical hazard you identify at your workplace. It’s advisable to then only look at the measures ranked 3-5 if there is no possible way of eliminating the hazard or finding a safer alternative.

In the next section, we’ll look at the steps you can take to start controlling chemical hazards by using the Hierarchy of Control.

The Hierarchy of Control should be applied to your work areas that carry any type of dangerous goods or hazardous substance.

Eliminating Chemical Hazards

‘Elimination’ as a hazard control measure means completely removing a chemical hazard. It can be achieved in a number of ways including:

| Hazard | Proposed elimination | Solution |

|---|---|---|

| Using a flammable adhesive to secure racking and shelves to the wall. | Stop using the chemical. | Use nails. |

| Constructing fibreglass surfboards and selling them. | Eliminating a manufacturing procedure. | Buying wholesale boards already constructed. |

| Mixing chemicals in the lab | Outsourcing a job task. | Buying pre-mixed chemicals. |

| Manufacturing plastic containers using chemical BPA (bisphenol-A). | Changing a manufacturing procedure. | Manufacturing only BPA free containers. |

NOTE: The above examples are for demonstration purposes and are not intended as practical solutions for your specific workplace situation.

It’s important to remember that eliminating a hazard is not about finding a safer way of doing the same job — it’s about never doing that job again.

And once you do eliminate a chemical hazard, you should always conduct another risk assessment on the affected work areas and job tasks to ensure that the hazard has indeed been completely eliminated.

REMEMBER: Sometimes eliminating a chemical hazard in one work area might create new hazards in others. Therefore, a follow up risk assessment is required to ensure that the elimination control has been successful and not created a further safety issue in your organisation.

Conducting a Risk Assessment After Eliminating a Chemical Hazard

To ensure that there are no new chemical hazards created in your workplace, you must conduct a further risk assessment after you’ve eliminated the hazard.

See the below table to understand the issues that can occur after a particular chemical hazard has been eliminated.

| Hazard | Solution | New problems/Hazard still present |

|---|---|---|

| Using a flammable adhesive to secure racking and shelves to the wall. | Use nails. | Nailing into an asbestos filled wall. |

| Constructing fibreglass surfboards and selling them. | Buying wholesale boards already constructed. | Having to trim down boards and modify them for clients. |

| Mixing chemicals in the lab | Buying pre-mixed chemicals. | Buying insufficient quantities and discovering staff are still mixing chemicals themselves. |

| Manufacturing plastic containers using chemical BPA (bisphenol-A). | Manufacturing only BPA free containers. | Hazardous manufacturing process still exists, there is just one less chemical. |

Substitution as a Chemical Control Measure

Substitution is about transitioning your worksite to safer ways of doing business by regularly assessing and reviewing the chemicals you use, handle and store.

And when you can’t eliminate a chemical hazard, your next best approach is to try and find something less harmful.

Here are a few examples:

-

Using a chemical that is less toxic, flammable, or corrosive (eg, changing from a flammable liquid to a combustible liquid)

-

Diluting chemicals so they are less concentrated (eg, using diluted cleaning products when dangerous goods are being used, stored or handled in the workplace)

-

Using the same chemical but in a different form (eg, in paste form rather than a powder which produces dust)

-

Introducing chemicals that don’t have multiple hazard classes (eg, switching to water based paints)

Substitution may involve selecting a safer chemical product to replace your current chemical.

Conducting a Risk Assessment After Substituting a Chemical Hazard

Once you’ve found a chemical that is less hazardous — or you’ve found a better way to carry out a job task — you’ll need to conduct a further risk assessment.

New hazards may be introduced to your workplace when a substitute chemical is less effective. Following your substitution of the hazard, you should be assessing whether:

-

The substitute chemical is actually getting the job done

-

If working conditions have changed

-

Whether staff have been properly trained in the new job procedures or are refusing to use the new chemicals

-

If there have been any other unforeseen effects

Finding an Effective Control Measure

Proactive workplaces do more than comply with legislation, they are constantly reviewing work methods, analysing their supply chain, and seeking chemical alternatives that are not only safer, but more cost effective too.

Eliminating or substituting hazards are the control measures that should be given the highest priority. For a more detailed explanation of the Hierarchy of Controls and how to eliminate or minimise chemical hazards, download our free eBook.

How to manage the risk of Hazardous Chemicals in the workplace offers practical instructions for getting your job site compliant. Our guide will introduce you for our 4-step risk management methodology, which can be easily applied to any workplace. Download our eBook and read it today by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.