When a workplace carries hazardous chemicals, the hazards created can be complex. These hazards can also be difficult to understand and challenging to control. However, employers have an obligation to protect workers from harm, as well as ensuring any surrounding properties and the environment are shielded from these hazards. In this post, we’ll be discussing elimination as a risk control measure for your workplace. We’ll also be highlighting the importance of workplace monitoring to ensure that you’re effectively eliminating chemical hazards through your controls.

Identifying Risk When Using Hazardous Chemicals

By their very nature, all hazardous chemicals present some degree of a danger to human health and safety. Your job as an employer is to assess the potential dangers and do whatever you can to either eliminate the chemical hazard — or reduce the risk to such a degree that your employees and contractors can work with chemicals safely.

You can’t eliminate or control any hazard if you don’t know they exist. Therefore, you’ll need to carry out a thorough workplace inspection everywhere chemicals are used or stored.

Elimination is the first and most effective control measure.

Check the safety data sheet (SDS) for a list of hazards, but also use your eyes, ears, and nose as risk indicators. A weird smell, smoke, or dust on machinery might indicate a hazardous substance generated during a work process.

Many chemical hazards are created by the way a substance is used or stored, so each chemical may have more than one hazard — especially if the substance is:

- Flammable - can the chemical burn or sustain a fire?

- Toxic - is the chemical poisonous if inhaled, absorbed, ingested, or swallowed?

- Corrosive - could the chemical erode or destroy living tissue, packaging materials and safety cabinets.

- Unstable - can the chemical explode or react dangerously with other substances?

- Environmentally reactive - could the chemical harm the environment and aquatic life?

If the chemical has multiple hazards, you may need to introduce several control measures to sufficiently minimise the harm. However, eliminating the chemical is always the most effective approach to controlling chemical hazards in the workplace.

What are Elimination Controls?

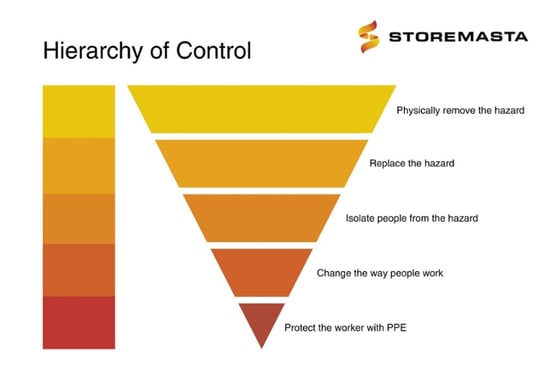

Elimination is a method of hazard control that forms the first step in the Hierarchy of Control.

The Hierarchy of Control is a recognised system that allows organisations to work through the step-by-step approach outlined in the control pyramid. As the first step in the Hierarchy of Control, elimination is considered as the highest level of protection, as well as the most effective form of control.

How to Use the Hierarchy of Control

If you’re wondering how to use the Hierarchy of Control in your own workplace, here is a brief overview:

Steps in the pyramid of the Hierarchy of Control are ordered from the most effective controls to the least effective:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- Personal Protective Equipment (PPE)

How to Eliminate Chemical Hazards

Using the Hierarchy of Control as your guide, you must start with aiming to eliminate all potential chemical hazards in your workplace.

If this is not possible for some chemical products, then you must move down the pyramid to the next control method, which is substitution. Substitution simply means substituting a hazardous chemical product for a less harmful option. The next steps in the Hierarchy of Control include the implementation of various controls. These include engineering controls (such as chemical storage cabinets or drum bunding) and administrative controls (including standard operating procedures for chemical handling or minimising chemical inventory onsite).

The final step in the Hierarchy of Control is the implementation of the correct personal protective equipment for your staff. This will be in line with the recommendations contained in each hazardous chemical’s safety data sheet, as well as information from the applicable Australian Standard for your chemical class.

The final step in the Hierarchy of Control is the implementation of the correct personal protective equipment for your staff. This will be in line with the recommendations contained in each hazardous chemical’s safety data sheet, as well as information from the applicable Australian Standard for your chemical class.

The control pyramid starts with elimination at the very top, as this is the ideal form of hazard control. After you’ve considered elimination in your operations, you can then systematically work your way down the pyramid towards personal protective equipment.

REMEMBER: While control measures reduce harm, the hazard still exists. Therefore, an elimination control will always be the most effective form of control as it completely removes the hazardous chemical from the workplace.

Example of Elimination Control

Consider a laboratory where operations depend on the use of sulphuric acid. This acid creates a chemical hazard as it could be spilled or inhaled by staff, which would result in harm.

Elimination of this chemical would only be possible if you removed the chemical from your inventory, as well as changing the existing work processes so that the hazardous chemical is no longer required.

To reduce the likelihood and impact of a chemical hazard, there are several controls that you could introduce to make the workplace safer.

A poly cabinet is considered an effective engineering control for safe storage of strong corrosives such as sulphuric acid.

For example, you could:

| CONTROL | EXAMPLE |

| Elimination | To eliminate the risk of chemical hazard, you could send the work tasks that involved sulphuric acid to an offsite facility. Alternatively, you could alter your onsite work practices, so that the acid is no longer required. |

| Substitution | If elimination is not deemed possible when controlling chemical hazards, you could substitute a less harmful chemical that provides a similar result as the sulphuric acid. |

|

Engineering Controls |

To control the chemical hazard posed by the sulphuric acid, you could use a dedicated acid cabinet made from high density polyethylene for storage. |

| Administrative Controls |

As part of your administrative controls, you may develop work procedures that ensure empty acid containers are never reused. This would reduce the likelihood of the acid harming staff due to the remaining residue or potential for chemical incompatibility. |

| Personal Protective Equipment |

For the protection and safety of your laboratory staff, you must ensure that you have the correct personal protective equipment available, such as chemical resistant gloves and goggles. You must also clean and maintain your PPE, so it remains in good working order. |

The Problem with Elimination Controls

Even though elimination is the most successful way of controlling chemical hazards, these elimination controls still need to be carefully monitored. Control measures may substitute or transfer the hazard to another area of your organisation.

All hazard control measures (particularly elimination controls) require regular monitoring and review. This can be in the form of safety audits and workplace inspections, but you also want to flag the area if exposure and spillage incidents are occurring or begin to increase.

Sometimes, when you tell staff that a hazard no longer exists and the area is now safe, they become less attentive to a work process and increasingly complacent. This change in attitude can actually lead to the creation of new hazards.

The best way to eliminate any hazard is to conduct a risk assessment during the design and planning stage of a project or development. According to the Risk Management Code of Practice released by Safe Work Australia:

“In these early phases, there is greater scope to design out hazards or incorporate risk control measures that are compatible with the original design and functional requirements.”

Basically, eliminating the hazard before it even reaches the workplace is always the most desirable method. This is the greatest way that you can improve the health and safety of your staff.

REMEMBER: Using a different (less harmful) chemical for the same work process is a substitution control. The hazard still exists even though the harm has been reduced.

Eliminate the Risk of Chemical Hazard

Now you have a better idea about how elimination controls work, why not download our free eBook? How to Manage the risk of Hazardous Chemicals in the Workplace is packed with practical information that will help you determine the best control measures for your own workplace. Download your eBook today and find out how to take decisive action to reduce chemical hazards at your workplace.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.