Class 6 dangerous goods are classified as toxic substances. According to the ADG Code, toxic substances can be defined as:

Substances that are liable to either cause death, serious injury or harm to human health from skin contact, ingestion or inhalation.

Aside from the immediate harm to human health, Class 6 chemicals can also cause chronic health effects through long-term exposure to lower concentrations of toxic substances. These health issues may include cancer or liver disease, which may result after months or years of exposure. In this post, we’ll be looking at the importance of Class 6 dangerous goods storage for the health and safety of your people — as well as your community and the natural environment.

Class 6 Dangerous Goods Examples

Toxic substances are used across a broad range of industries and can be found in a variety of items such as cleaning solutions, cosmetics and packaging products.

Some common toxic substance examples that you may find in the workplace are:

- Pesticide chemicals

- Lead

- Mercury

- Asbestos

- Lead

- Sodium Azide

- Hydrogen Peroxide

- Methylene Chloride

Importance of Class 6 Dangerous Goods Storage

When you’re carrying any type of dangerous goods in your organisation, it’s vital that the substances are stored in the correct way.

Failure to store (and handle) toxic substances in a safe and compliant manner can have other negative implications — aside from causing harm to human health.

If toxic chemicals were released into the environment — through accidental leaks or spills — they could have a major impact on living systems, which would have a cumulative effect on the food chain.

Also, if toxic substances are not stored and managed according to the Australian Standards, there is a risk that your organisation will be financially liable due to non-compliance.

Toxic substances can impact on human and animal health, as well as the environment.

As Class 6 dangerous goods can harm human health, pollute the environment and create financial liability of your organisation, it’s crucial that you understand how to store and manage them in a safe, compliant manner to reduce the risk of incidents.

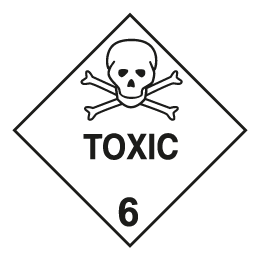

Toxic 6.1 Sign Meaning

The dangerous goods diamond that represents toxic substances must be displayed in any area that stores Class 6.1 substances, including on any indoor storage cabinets or outdoor toxic substance storage containers.

Just like other dangerous goods diamonds, the toxic 6.1 sign is a physical representation of the chemical class that is stored at your premises.

An example of the toxic substances sign is shown below:

The illustration of the skull, with the word TOXIC and number 6, is an easily recognisable sign that should alert all staff and personnel to the danger associated with the toxic chemicals at your site.

Your Class 6.1 sign is required by WHS Law and Regulations to be clearly displayed and maintained on all toxic substance storage areas.

Requirements of AS NZS 4452:1997

The Australian Standard that outlines the requirements for the storage and handling of toxic substances is AS NZS 4452:1997 - The storage and handling of toxic substances.

Whether you’re storing these chemicals indoors in a toxic storage cabinet or you’re housing toxic substances outdoors in a chemical or DG storage container, Class 6 substances must be contained so they don’t cause harm to people, animals and the environment.

We’ll now outline the key requirements for the indoor and outdoor storage and handling of toxic substances in the workplace.

Indoor Storage of Toxic Substances

If your organisation only uses smaller quantities of toxic substances, AS NZS 4452 gives you the provision to store these substances indoors.

Toxic substances that are stored indoors must be kept in a compliant safety cabinet that has been manufactured in full conformance to AS NZS 4452.

The maximum quantities of toxic substances that can be kept in an indoor storage cabinet is 250L.

Toxic storage cabinets offer a range of controls to reduce the risks associated with Class 6 dangerous goods.

The design and construction requirements of indoor toxic storage cabinets are outlined below:

- The walls, floor, door and roof of the cabinet must be of a double walled sheet steel construction have a thickness of at least .75mm. The air gap between the walls must be at least 40mm.

- The cabinet must have self-closing, close-fitting doors.

- Any shelves within the cabinet must be perforated to allow for free air-movement.

- The cabinet must be lockable to prevent unauthorised access.

The bottom of the cabinet must form a liquid-tight sump that is at least 150 mm deep and capable of containing at least 25% of the aggregate storage capacity of the cabinet.

If a mechanical ventilation system is required, it must be designed by an appropriately qualified engineer.

Considering mechanical ventilation for your toxic cabinets?

Outdoor Storage of Toxic Substances

There are a number of facilities that can be used for the storage of toxic substances. However, due to cost-effectiveness and convenience, most organisations like to use relocatable chemical storage containers that have been designed and manufactured in full conformance with AS NZS 4452.

These toxic storage containers are the safest and most efficient method for storing toxic substances in the outdoor environment.

Outdoor toxic substance storage containers must be designed and constructed with a range of features, as per the requirements of the Australian Standards. We’ll explain these requirements in detail below.

Store Class 6 chemicals outdoors in a compliant toxic storage container that meets all the requirements of the Australian Standards.

Construction

Outdoor toxic substance storage containers must be constructed with certain specifications to reduce the risk of incidents.

These requirements include:

- If a store has a floor area exceeding 25m2, it must have at least 2 means of access in and out of the store.

- Toxic substance stores must have walls and a roof and the main structural members must be non-combustible and resistant to attack from the harsh chemicals stored within the store.

- The floor of the container shall be designed in a way that allows it to be washed down with water.

- All areas within the store that are used for decanting shall have a floor that is capable of containing spills.

- The store shall be secured to prevent unauthorised entry.

- Racks and shelves within the container must be designed and constructed in such a manner that prevents the accumulation or pooling of toxic liquid.

- Any racking inside the container shall be designed in a way that provides a clear path of escape for emergencies.

Spillage Containment

To prevent toxic substances from leaking into the environment, toxic substance storage containers must have the means to contain any spills that may occur within the store.

The required spill containment capacities are outlined in section 4.4.1 of AS NZS 4452.

The net capacity of any spill containment compound shall be:

- For packing group 1; 100% of the aggregate volume of liquids kept

- For packing group 2; 25% of the aggregate volume of liquids

In all instances, the net capacity of the spill containment sump shall be at least the capacity of the largest container kept within the store.

Ventilation

Of the three different routes of exposure, inhalation is the most common form of exposure. To reduce the risk of intoxication from inhalation, outdoor chemical storage containers must be provided with adequate natural ventilation to keep the concentration of toxic vapours as low as practical.

If the toxic substances within the store are listed in the workplace exposure standards, the airborne concentration of the toxic substances within the store must be kept below the maximum limits outlined in the workplace exposure standards.

Provision of Safety Showers and Eyewash Stations

To reduce the likelihood and impact of intoxication from toxic chemical exposure, an eyewash station and safety shower must be installed next to all Class 6 storage containers.

The eyewash station and safety shower must be provided within 7 metres, but no closer than 2 metres of the toxic substance store, so it can be accessed quickly by staff.

Class 6 Storage

As toxic substances can have severe effects upon human health, the environment and the financial liability of your organisation, they must be stored and managed in a way that reduces chemical risk.

Toxic chemicals can be safely stored by following the guidelines in this article and adhering to the requirements outlined in AS NZS 4452. If you’d like more information on the properties of Class 6 Toxic Substances and other classes of dangerous goods, why not access our free eBook today? Our guide will help you better understand your onsite dangerous goods, so you can create a more compliant workplace.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.