It doesn’t matter if you’re carrying a few drums or multiple IBCs, if you have hazardous chemicals or dangerous goods at your site, you could be at risk of a HAZCHEM spill. And while secondary containment measures are a requirement of WHS Regulations and Australian Standards, it’s often difficult to determine your spill bunding needs. Whether you’re working on a remote site in the mining industry or you’re storing chemicals outside your manufacturing plant, portable collapsible bunding is a spill containment option that may be suitable for your operations. But what exactly is portable collapsible bunding — and why do you need it in your workplace?

In this post, we’ll be taking a deep dive into portable spill containment — explaining what you need to consider when assessing, selecting, installing and maintaining your secondary containment system.

So, What Is It?

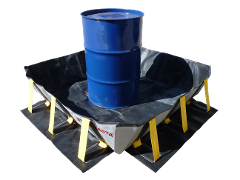

Otherwise known as a collapsible spill bund or spill berm, portable collapsible bunds are a flexible and cost-effective bunding option. This type of bund can be used for temporary or permanent spill containment in either an indoor or outdoor environment.

Portable collapsible bunding is suitable for both indoor and outdoor use.

Due to the maneuverable and lightweight design, portable bunds are commonly used in remote sites, as well as more permanent operations. They are particularly popular on mining, oil and gas, and industrial work sites.

REMEMBER: Your spill bunding system may be a mixture of both permanent and temporary bunds. We suggest you conduct an onsite risk assessment to thoroughly assess your hazardous chemical spill containment needs.

How Are They Manufactured?

Manufactured with heavy duty PVC or state-of-the-art XR-5 geomembrane, collapsible bunds offer a range of features including:

- UV resistant

- Suitable for extreme temperatures

- Resistant to tear and punctures

- Durable

- Capable of containing a wide range of substances

- Collapsible portable bunding can be used as drive over bunding

- Fast deployment

- Able to be folded up when not in use

- Low maintenance and easy cleaning

- Self-extinguishing, fire-retardant properties

Portable collapsible bunds offer fast deployment and easy cleaning.

They are able to be used in temperatures ranging from -20 to 70°C, which makes them suitable for use outdoors in Australia’s harsh climate.

REMEMBER: You can reuse your collapsible bunds as long as they are properly cleaned and stored after use. Always check for signs of damage before you use your bunds, looking for any small tears, punctures or abrasions in the PVC or XR-5 material.

What Can You Use Portable Collapsible Bunds For?

Almost any chemical container, including ISO tanks, IBCs and drums, can be protected from spillage with the deployment of a portable collapsible bund.

Vehicles and equipment, including heavy machinery, trucks and cars, can also be parked on the bunds. This allows staff to carry out washdowns, servicing, repairs, re-fueling and other necessary operations with spill protection .

By preventing spillage of diesel, petrol and oil, staff are avoiding the contamination of the natural environment. They are also minimising the risk of fire or explosion with these flammable liquids.

Without the deployment of collapsible bunding, it would be difficult to contain a leak or spill if it occurred in this type of environment.

Collapsible bunding are an ideal solution for containing leaks and spills from equipment, vehicles and machinery.

Common uses for this type of bunding include:

- Indoor or outdoor chemical spill containment

- Temporary bunded storage

- Wash down bays for vehicles

- Drive on and drive off fuel transfer areas

- Servicing and repair areas for heavy machinery

- Decanting stations

Portable bunds, just like all types of secondary spill containment, are available in a range of capacities to suit a variety of applications. As this type of bund can be used with equipment, vehicles as well as large chemical packages, the capacity of the portable bunding can be up to 1728 litres.

REMEMBER: A risk assessment of your onsite chemicals will be able to determine the capacity of the portable collapsible bund that you’ll need. Consult with a Dangerous Goods Specialist or refer to the Australian Standards for the spill containment requirements that relate to your onsite dangerous goods.

What Makes Them Unique?

If you’re familiar with spill containment systems, you’ll understand that portable collapsible bunding is a unique option.

Portable bunding is particularly useful in situations such as remote work site — or for use in vehicle, equipment and machinery re-fueling or maintenance areas. However, this type of bunding shouldn’t be used in static situations where bunded storage, IBC bunds, drums bunds or floor bunding is a preferable option. A range of chemical packages can be used with portable collapsible bunding including drums, pallets, IBCs and ISO tanks.

A range of chemical packages can be used with portable collapsible bunding including drums, pallets, IBCs and ISO tanks.

Portable collapsible bunds offer unique features including:

- Constructed with materials that can be folded and deployed quickly

- Bund stands made with marine-grade batten for strength of structure

- Suitable for drive in applications

IMPORTANT: If you’re unsure if you should be choosing permanent or temporary bunding for your application, get in touch with our Dangerous Goods Specialists who can help you determine your spill containment needs.

What Material Is Suitable?

Hydrocarbons, such as fuel and oil, chemical acids, and other harsh substances may be suitable for use with portable collapsible bunds. As there are two options for bunding materials — that is PVC and XR-5 — you should check the chemical compatibility of the bunding with your chemical products to ensure that it is suitable for use.

Generally speaking, the PVC bunds are more suitable for milder chemicals, whereas the XR-5 material is compatible with many harsher chemical products. Always consult the manufacturer or supplier if you’re unsure if your bunding is suitable for your onsite chemicals.

Are There Accessories Available?

Due to the wide range of applications that portable bunding lends itself to, there are also a range of accessories which can be used with the bund. These include:

- Carry bag for fast, easy deployment

- Repair kit to quickly fix small tears or punctures in the bund

- Ground mat for protection in harsher environments

- Liner for extra protection against harsh chemicals or punctures

If you want to increase the speed and efficiency of your spill clean-up, you can also fit drain ports to your collapsible spill bunds. This allows for pump out access of your bund.

REMEMBER: Just like any piece of dangerous goods storage or handling equipment, your portable bunding products must be free of hazardous chemical substances and residue after they have been used. If you’re using flammable, toxic or other harsh chemicals, make sure the bunding is properly washed down and decontaminated after it’s been used.

Understanding Portable Spill Containment

When it comes to containing and managing any hazardous spillage, it’s important to have a system in place that meets your compliance obligations. This may involve using a mixture of permanent bunding and temporary bunding for your worksite.

As we’ve highlighted, portable collapsible bunds offer a range of benefits for organisations who are working remotely or using machinery, equipment or vehicles. The capability for a drive in and drive out application makes this type of bund a particularly unique and useful solution for spill containment, however, portable bunding may need to be used in conjunction with other permanent bunding measures, such as bunded chemical storage.

To learn more about preventing chemical spills and meeting your compliance obligations, why not access our free eBook. How To Protect Your Business From Chemical Spills details the requirements for each class of dangerous goods and illustrates a range of bunding options that may suit your operations. Grab your copy of our guide for free now by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.