When you’re working with hazardous liquids on a jobsite, spill containment needs to be a top priority. And while you may be using a range of containment measures – from drip trays to bunded storage containers and handling equipment – there are many operations that also require a temporary containment solution. Collapsible spill bunds are used across a broad range of industries and are recognised for their simple, lightweight and durable design. But how do you choose the correct bunding for your operations and how easy is it to setup? In this post, we’ll be giving you all the essential details on portable collapsible spill containment so you can protect people, property and environment from hazardous leaks and spills.

Selecting The Right Bund

If you’re looking for temporary bunding, there are a few different options available. But first, you’ll have to consider the following questions:

- What chemical products are you looking to contain?

- How much liquid could be accidentally released?

- What kind of environment will the bund be placed in?

Answering these questions will help you determine your portable collapsible bunding requirements, so you have the correct material, adequate capacity and suitable accessories for your containment system.

Consider the type and quantity of chemicals that will need containment, as well as the environment in which you’re using the temporary spill bund.

Chemical Compatibility

From flammable liquids to toxic substances, temporary bunding may be used with a vast range of hazardous chemicals.

The compatibility of your bunding with your chemical products is a key safety issue that you must consider before you purchase and deploy your containment system.

Portable collapsible bunding is made for specific situations where permanent bunding is not suitable. These applications can include drive in wash bays, temporary bunded storage for chemical packages, decanting applications and vehicle re-fueling areas.

Temporary bunding is particularly useful when re-fueling, washing down, servicing or repairing equipment and vehicles.

As the bunding is designed to withstand chemical attack — and not create further chemical hazards in the event of a leak or spill — you must make sure that your chemicals are suitable for the bunding that you choose.

Our collapsible bunding is made with two types of materials: heavy duty PVC or XR-5® geomembrane. While these materials offer flexibility, strength and durability, you must select the material that is chemically compatible with the substances that you’re wanting to contain.

IMPORTANT: XR-5® Geomembrane is an innovative material which is suitable for many harsher chemicals. This synthetic woven geomembrane is compatible with a wide range of harsh substances including highly flammable or corrosive chemicals.

While confirmation about the suitability of the chemical for the bund material should be sought upon purchase, there are some general guidelines which may assist in your selection of bund material.

Heavy Duty PVC may be suitable for milder chemical substances such as:

- Carbon Dioxyde

- Citrique Acid

- Diethyl Ether

- Oleic Acid

- Peanut Oil

- Phosphoric Acid

- Potassium Chrloride solution

- Raw Linseed Oil

- Sodium Bicarbonate

XR-5® Geomembrane may be suitable for some harsher chemical substances such as:

- Petrol

- Diesel

- Ethanol

- Fuel Oil

- Sodium Hydroxide

- Sulphuric Acid

- Transformer Oil

- Turpentine

Some harsher substances are suitable for use with a XR-5® Geomembrane temporary bund, but you should always check with your chemical supplier, and the manufacturer’s recommendations, before purchasing the bund.

How Do You Choose The Right Size Of Bund?

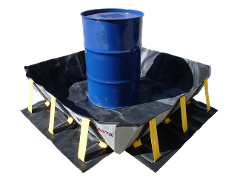

Collapsible spill bunds, just like all types of secondary spill containment, are designed to suit a wide range of applications.

As this type of bund can be used with tanks, IBCs, equipment and vehicles, you’ll need to carefully assess your spill containment requirements before purchasing a suitable bund.

The capacity of your portable bunding varies with the specific bund models, with options ranging from smaller applications that have the capacity for several hundred litres of chemicals to large portable spill containment systems that can hold over 1000 litres of chemicals.

Select the bunding that suits not only the capacity of your chemicals, but the size of the equipment, chemical packages or vehicles that will be used with the temporary spill containment system. Make sure the bund you’re selecting is large enough and has enough capacity to comfortably accommodate the chemicals, as well as any transfer equipment such as cranes or forklifts.

Make sure the bund you’re selecting is large enough and has enough capacity to comfortably accommodate the chemicals, as well as any transfer equipment such as cranes or forklifts.

The footprint of the bund will be 1 metre wider and longer than the internal measurement, so make sure that you’re allowing enough space for the bund (and the ground mat that is placed underneath it).

You’ll also have to be aware of gaining access to the site, for both staff, vehicles and any forklifts or cranes which are loading into the bund.

If you are pumping out from the temporary bunding, you must also make sure it’s large enough for your operations and the pumping equipment.

STOREMASTA’s range of collapsible bunds include:

- 1200 W x 1200 D with 432 litre capacity

- 1800 W x 1800 D with 972 litre capacity

- 2400 W x 2400 D with 1728 litre capacity

How To Deploy The Portable Spill Bund

Deploying the portable bunding should only take a matter of minutes. If you have a larger collapsible bund, you may require extra staff for assistance with the setup and pulldown of the equipment.

However, smaller bunds can be easily erected by a single staff member, in a short period of time.

Consider these steps for setup of the portable bund:

- Choose the site and clear the ground for debris

- Lay out the ground mat to protect the bund from tears, abrasions and damage

- Fold out the temporary portable bunding into the centre of the ground mat

It's now time to erect the temporary bunding:

- Deploy each of the bund legs, so the wall can be erected

- Extend the leg joint away from the bund and secure it by pushing it down into the seam. The seam is where the wall meets the base of the bund

- Your bund should now be taking the shape of a walled enclosure

- If you choose to use a liner, unfold it and place this within the enclosure

Do you require a drive-in bund or portable wash bay?

- Simply collapse a single bund wall for the vehicle to drive into

- Cover the collapsed wall with a liner if your bund requires extra protection from the tyres

- After the vehicle or equipment is in place, erect the collapsed wall to maintain the spill enclosure

REMEMBER: Accessories including a ground mat, liner and carry bag are available as an optional extra upon purchase of your collapsible bunding product.

How To Fold Up The Portable Bund

After your work tasks have been completed, you can then clean, decontaminate, dry and fold up the bund — and liner, if applicable.

REMEMBER: Hazardous chemicals can pose risk if there is a substance or residue left on the bund. Make sure that your staff are following the necessary procedures to clean up and decontaminate the bunding after it’s been used.

Follow these steps to fold up the portable containment bund:

- Collapse the legs of the bund by pulling up the bottom part of the leg (which was pushed into the bund seam)

- You can remove the liner, if you have one, or leave it in the bund

- Continue to collapse each leg of the bund but don’t yet fold down the wall

- Once all the legs have been collapsed, you can fold down one wall of the bund

- Then go to the opposite wall and fold that down

- Continue to fold down the other two walls in sequence

- You can then fold up the bund, making sure the legs are aligned

- Fold the bund up evenly, from the outside to the middle

- Take up the ground mat

- Place the folded bund in the carry bag and return it, and the accessories, to storage

IMPORTANT: Make sure your temporary spill containment bund is clean and dry before it’s folded up and placed back in its carry bag. If your bund has suffered any damage during the process, it may be able to be repaired by utilising the bund repair kit. However, if the temporary bund does suffer extensive damage during use, make sure that it’s replaced immediately. Any issues with the bund will decrease its effectiveness as a spill containment system.

Choosing and Using Your Portable Bund

When selecting portable bunding for your operations, always consider the application, the size of the equipment or chemical packages, the required bund capacity, and the chemical compatibility with the bunding material. Portable bunds are a convenient and cost-effective spill containment solution that are used across a range of industries.

To find out more about the containment of hazardous chemical spills, you can download our latest eBook. How To Protect Your Business From Chemical Spills offers expert advice on secondary containment measures and details the requirements for spill capacity. By understanding your bunding and secondary containment options, you can better protect the people, property and environment of your organisation from hazardous chemical leaks and spills. Access your free copy today by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.