Do the chemicals at your site have flammable and corrosive properties? When you’re working with dangerous goods, there are many risks that need to be controlled to maintain a safe working environment. However, chemicals that are both flammable and corrosive pose a wide range of risks that require careful procedures and work practices to keep a safe, compliant workplace. In this post, we’ll be looking at ways that you can reduce risk with your flammable and corrosive substances.

But before we get into our chemical safety tips, let’s first look at flammable chemicals and corrosive substances to find out what risks these dangerous goods classes each pose in the workplace.

Risks Associated With Flammable Liquids

Recognised as Class 3 dangerous goods, flammable liquids are commonly used substances that are utilised by a wide range of industries. Workplaces that handle and store flammable liquids include manufacturing businesses, oil and gas operations, mining sites, hospitality businesses, educational institutes and medical organisations.

Flammable liquids pose a range of serious risks — with the risk of ignition being one of the key concerns for companies that carry these chemicals.

Class 3 substances give off high volumes of flammable vapours at temperatures under 60 °C (closed-cup test) or 65.6 °C (open-cup test).

Flammable liquids can give off sufficient flammable vapours at low temperatures to spark a fire or explosion, if vapours meet an ignition source.

These flammable vapours, if they happen to meet an ignition source within your workplace, can quickly ignite. This can result in a fierce fire, flashback or flammable liquid explosion. Flammable liquids are dangerous because they have the ability to ignite at low temperatures (under 60 °C) —which is the temperature range found in many Australian workplaces.

There are several chemical controls which must be implemented and maintained when dealing with flammable liquids in the workplace.

These include:

- Vapour control – your flammable liquids can release flammable vapours, which can lead to human harm through asphyxiation and fire or explosion, if the vapours meet an ignition source

- Spill containment – chemical leaks and spillage can occur in any area that handles, transfers or stores flammable liquids. Spills must be contained and managed to reduce the risk of human harm, property damage and environmental damage

- Isolation of ignition sources – the Australian Standards for flammable and combustible liquids dictates that ignition sources should be isolated from any Class 3 liquids by a distance of at least 3 metres

- Chemical segregation – being a volatile substance, flammable liquids must be segregated from other classes of dangerous goods. However, they are compatible with other Class 3 liquids, so they can be stored with other flammable substances.

Risks Associated With Corrosive Substances

Corrosive substances are also commonly found across many Australian workplaces. However, one unique feature of corrosive substances is their ability to corrode living tissue, metal and other materials.

Handling and storage of corrosive substances must reduce the risk of human harm, property destruction and environmental damage.

This makes the storage and handling of corrosive substances a particularly complex process. While storage facilities can be lined with corrosion-resistant liners and spill trays, the direct handling (ie. without PPE) of corrosive substances is prohibited due to the extreme risk of human harm. Health issues that can occur when staff are exposed to corrosive liquids or fumes include chemical burns, eye damage and respiratory issues.

When considering chemical controls for your stores of Class 8 Corrosive Substances, make sure that you minimise the risk of:

- Corrosion – these chemicals can instantly affect any surface that is susceptible to corrosion. This includes living tissue (such as the skin or eyes), metal (sheet steel) and other materials commonly found in the workplace, such as stone.

- Human harm – apart from the risk of destruction of living tissue, corrosive substances can cause a range of health issues for the humans (animals, wildlife or marine life) that come into contact with these chemicals. Issues may include irritation to eyes or skin, damage to the respiratory tract and the digestion system.

REMEMBER: If corrosive vapours or liquids spill into the natural environment, it can quickly contaminate soil, waterways and any animal life that it sustains. Vapours, as well as the actual chemical substance, can cause acute health issues for both humans and animals, so the strict control of corrosive substance spills is essential for chemical safety.

What Chemicals Are Flammable and Corrosive?

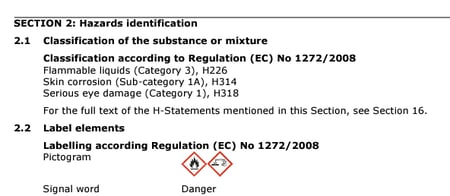

Some chemicals are recognised as a dangerous goods class — with a sub-risk of another class.

This means, that your chemical handling and storage practices should not only be compliant with the requirements for the primary dangerous goods class, but they should also adhere to the requirements for the secondary chemical class that is identified as the substance’s sub-risk.

Refer to the SDS of your particular chemical product to determine the primary and sub-risk of the chemical that you’re carrying.

Essentially, chemicals that are flammable and corrosive pose a vast range of risks, including fire, explosion and corrosion — as well as the release of harmful vapours, in certain circumstances.

However, this doesn’t mean that it’s difficult to control these risks – it simply means that you should be catering for both classes of dangerous goods in your handling and storage practices.

IMPORTANT: The storage of the main chemical class needs to take preference when determining your dangerous goods storage needs. You can then follow this by implementing measures to control the risks of the secondary chemical class.

Some chemicals which have both flammable and corrosive properties may include:

- Alkylamines

- Polyalkylamines

- Acetic acid

- Peracetic Acid

Key Controls To Consider For Flammable and Corrosive Chemicals

Due to the vast range of risks posed by flammable and corrosive substances, there are a myriad of chemical controls required for the safe handling and storage of these dangerous goods.

Flammable and corrosive chemicals must be handled and stored to reduce a wide range of risks.

Considerations should include:

- PPE – personal protective equipment, including breathing apparatus, must be supplied to staff working with flammable and corrosive chemicals. While flammable vapours are also harmful to human health, the corrosive substance and its dangerous vapours can cause serious health issues if workers are exposed to the chemical product.

- Emergency decontamination equipment – emergency equipment, such as eye wash stations and safety showers, must be installed after a risk assessment is conducted at your site. There are multiple requirements that relate to the installation of emergency decontamination equipment, so check with the Australian Standards to see if your store or work area requires this equipment.

- Protection from chemical attack – due to the fact that Class 8 chemicals can corrode metals, such as sheet steel, it’s crucial that any storage or handling equipment is resistant to chemical attack. This may mean that storage facilities are equipped with PVC linings and spill trays to protect against corrosive substances.

- Chemical segregation – being flammable and corrosive, we recommend storing these chemical products away from other classes of incompatible dangerous goods. Chemical segregation is possible within dedicated safety cabinets, however, other chemical stores will have to adhere to the dangerous goods segregation guidelines, at a minimum of 3 metres in distance from incompatible substances.

- Isolation from ignition sources – due to the risk of ignition with Class 3 substances, ignition sources should always be identified and isolated during the initial risk assessment of your site. This includes sources of ignition such as naked flames, lit cigarettes, welding equipment, hot work, power points, and heated surfaces. Make sure the area has clear signage prohibiting ignition sources from being brought into the work or storage area.

- Ventilation – both flammable and corrosive vapours can cause risk to the organisations that hold these types of chemicals. Therefore, you should always refer to the legal limits set by the workplace exposure standards, to determine if the concentration of airborne contaminants in your organisation is within a safe level. Ventilation, natural or mechanical, may be required if your stores and work areas come within the legal limits for hazardous vapours and gases.

- Spill control – ensuring spill containment and management of flammable and corrosive substances is crucial for the safety of your people, property and the natural environment (and its inhabitants). Consider a system of spill containment including bunded storage cabinets and outdoor chemical containers, bunded handling equipment, floor bunding and even temporary portable bunding where appropriate,

REMEMBER: As chemicals may have a primary and sub-risk class, always refer to the Safety Data Sheet of each individual substance to determine the specific handling and storage requirements for that product.

Handling and Storing Class 3 and Class 8 Substances

While there are many factors to consider when bringing a flammable and corrosive chemical into your workplace, there are also many ways that you can actively reduce chemical risk in your operations.

From PPE to ventilation and the appropriate bunded storage, you can minimise the risk of fire, explosion and corrosion when implementing control systems within your workplace.

To find out more about controlling the risks associated with hazardous chemicals and dangerous goods, you can download our helpful eBook. Our guide details our 4-step risk control methodology, which will help you identify, assess, control and review risks in your own organisation. Grab your own copy for free today by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.