Corrosive substances are very harmful chemicals that pose a great risk to people, property and the environment. The most dangerous property of a corrosive substance is its ability to dissolve materials, such as metal, stone, wood and human flesh, through chemical action.

Defining Corrosive Substances

The Australian Dangerous Goods Code (ADG Code) classifies corrosive substances as Class 8 Corrosive Substances.

‘Class 8 substances (corrosive substances) are substances which, by chemical action, will cause severe damage when in contact with living tissue, or, in the case of leakage, will materially damage, or even destroy, other goods or the means of transport.’

As corrosive substances have the ability to cause harm in the workplace, it's vital that corrosive substances are stored in a safe and compliant manner.

Corrosive chemicals can damage the health of those handling these dangerous goods, as well as harm the environment and corrode tools, equipment, vehicles and other materials at your site.

Australian Standard for Corrosive Storage

The Australian Standard AS 3780 - The storage and handling of corrosive substances, outlines the requirements for the safe storage and handling of corrosive substances in the workplace. Section 4.6 of the Standard explains the specification for indoor storage of corrosive substances.

Corrosive cabinet requirements include information on the following topics:

- Corrosive cabinet design

- Chemical segregation

- Maximum quantities stored

- Cabinet location

- Cabinet markings

We’ll discuss these requirements in the next section of our blog, so you can get a better understanding of how to store corrosives indoors in a safe manner.

Corrosive Cabinet Design

When storing corrosive substances indoors, it's important that the cabinet used is designed in such a way that it poses minimum risk to people property and the environment. To achieve this the cabinet must be designed and manufactured with certain features.

These features include:

- The cabinet must have self-closing, close-fitting doors that hold shut by at least two catches.

- The doors must be prevented from opening inwards.

- The doors of the cabinet must be capable of being opened from inside the cabinet.

- The base of the cabinet shall form a liquid-tight sump that must be at least 150mm deep. This sump must have the capacity of holding at least 25% of the maximum capacity of the storage cabinet.

- Shelves inside the cabinet must be perforated to allow for free air-movement within the cabinet.

- The walls, floor, door and roof of the cabinet must be constructed from either a corrosive resistant material or protected with a corrosive resistant lining or coating.

Corrosive storage cabinets must meet the requirements of the Australian Standard to be deemed compliant.

Types of Substances Stored

Cabinets used for the storage of corrosive substances must not be used to store other incompatible dangerous goods.

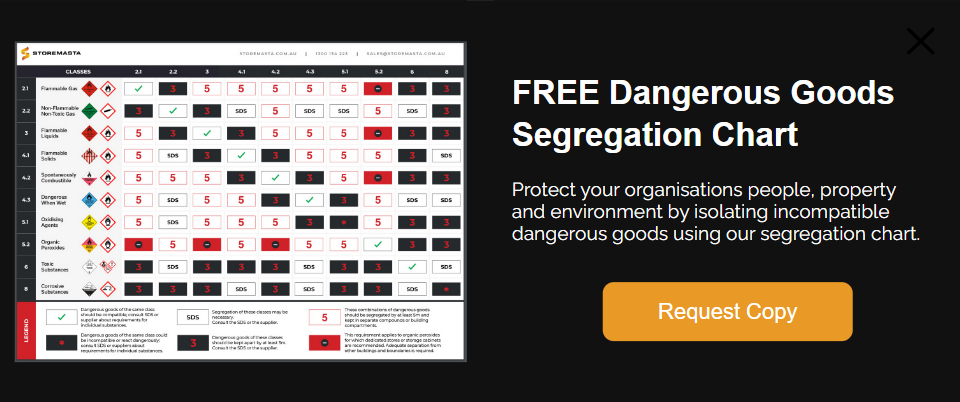

Incompatible dangerous goods may react dangerously and release toxic and corrosive gases and substances. Therefore, strict chemical segregation is required when storing corrosive substances.

Some classes of dangerous substances that are incompatible with Class 8 Corrosives include:

- Class 3 Flammable Liquids

- Division 5.1 Oxidising Agents

- Division 5.2 Organic Peroxides

If you have multiple classes of dangerous goods at your worksite, you need to have multiple cabinets – constructed to meet the requirements of that particular DG class – to store each of these chemical classes safely.

Are you segregating your DG?

Maximum Storage Quantities for Corrosives

As corrosive substances can dissolve wood, stone, metal and human flesh, it’s important to limit the quantities that are stored indoors.

The maximum quantities of corrosive substances kept in a single cabinet shall not exceed 1000 kg or L.

Of that 1000 kg or L, no more than 250 kg or L shall be of packing group II and not more than 50 kg or L shall be of packing group I.

Note: Units of litres are applicable to liquids and units of kilograms are applicable to solids.

Cabinet Location

To ensure that corrosive substances pose the least amount of risk to people in the workplace, it’s important to position corrosive storage cabinets in a safe location. For the location of corrosive storage cabinets to be safe, they must follow the requirements outlined below:

- Corrosive storage cabinets shall not be positioned in a location where they will impede the escape of a person in the event of a fire.

- Corrosive storage cabinets shall be located in a position where there is the provision for the washing of hands.

Aggregate Quantities

Where there is more than one corrosive storage cabinet in a building or area; the aggregate quantity of corrosive substances stored in all cabinets shall not exceed 1000 L. Of this 1000 L, no more than 250 L shall be of Packing Group II and no more than 50 L shall be of Packing Group I.

The cabinets shall also be separated by at least 5m.

Cabinet Markings

To ensure that everyone in the workplace, including workers and visitors, are warned of the potential hazards associated with corrosive substances, it's important to display the appropriate safety signage on all corrosive storage cabinets.

The signage requirements for corrosive storage cabinets will be outlined in the relevant regulations and codes of practices for your state or territory.

The specific design of dangerous goods placards must also comply with the requirements of AS 1216-2006 - Class labels for dangerous goods.

In states where there are no regulatory requirements, each corrosive storage cabinet shall be labeled with specific markings.

These markings include:

- Name of the address of the cabinet manufacturer, importer or distributor in Australia.

- A label stating the maximum storage capacity

- A Class 8 dangerous goods label with sides of at least 100 mm in length.

In all instances, the signage on your chemical storage cabinets must be visible when the doors of the cabinet are closed. Cabinet markings must also be regularly inspected and maintained, so it stays in good condition.

Compliant Storage of Corrosive Chemicals

To ensure the safe storage of corrosive chemicals, you should follow the requirements of the Australian Standard. One important aspect of safe storage is ensuring that you segregate corrosive substances from other incompatible classes of dangerous goods, such as flammable liquids.

The compatibility of different classes of dangerous goods can be determined by using a dangerous goods segregation chart. Use our guide to improve corrosive substance safety in your organisation.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.