If you’re running a winery, brewery or distillery, ensuring chemical safety is a key consideration. Ethanol, along with other chemicals that are necessary for alcohol production, is classed as a dangerous good. In fact, as a flammable liquid, ethanol can spark a range of dangerous incidents including asphyxiation, fire, flashback and explosion. In this post, we share 6 key chemical safety tips that relate specifically to the operation of wineries, breweries and distilleries. We hope that our blog can help you better understand chemical hazards, so you can decrease risk in your own operations.

Alcohol Production and Chemical Safety

While we don’t always think about alcohol being classed as a dangerous good, ethanol is regarded as a Class 3 Flammable Liquid.

Whether you’re running a small micro-brewery, or you manage an established distillery, if you’re producing alcoholic beverages, you need to know how to handle and store Class 3 chemicals.

The production of alcohol can involve various chemical substances including flammable liquids.

Flammable liquids, as the name suggests, can quickly ignite — causing serious incidents such as fire, flashback and explosions. Therefore, specific measures must be in place to reduce the likelihood of these accidents occurring in your own business.

Class 3 Flammable Liquids can become volatile and dangerous when:

- The flammable vapour emissions meet an ignition source

- Flammable liquids spill into work areas, creating an ignition risk or a high concentration of harmful vapours

- Chemicals are stored near, or handled close to, incompatible substances or those that react dangerously

- Liquids leak into the natural environment, into soil, down drainpipes, or into waterways

Flammable Liquid Fires

Unfortunately, you don’t have to look too long to find real-life examples of flammable liquids causing destruction and damage to businesses who produce spirits, wine or beer.

One of the most horrific blazes occurred at the Heaven Hill Distillery in Kentucky, where the ignited whiskey created a river of fire. The blaze destroyed the distillery, plus seven rickhouses and around 100,000 barrels of whiskey.

Another fire destroyed the Jim Beam warehouse in Woodford County, Kentucky. Caused by a lightning strike, it consumed around 45,000 barrels of bourbon and contaminated the Ohio River with runoff.

Due to the large quantities of alcohol kept on these premises, as well as the distilling process itself, there are a range of risks that need to be controlled when producing alcohol.

Your Duties Under WHS Law

Breweries, distilleries and wineries are classed as manufacturing businesses within the food and beverage industry.

Every person in the workplace has a duty of care under the model WHS Act. This means that you are obligated to ensure the health and safety of workers and others in your organisation. This is to be achieved through the identification, assessment and control of risks, as well as the review of risk control measures.

Breweries, distilleries and wineries must operate in a way that reduces chemical risk.

For companies that produce alcohol and alcohol-related products, a key health and safety issue lies within the handling and storage of hazardous chemicals.

Steps Towards Chemical Safety

To effectively manage the risk of working with hazardous chemicals, such as ethanol and Class 3 Flammable Liquids, there are a range of measures that can be implemented, maintained and reviewed.

These steps allow organisations to better understand the chemical risks present in their operations. It also enables businesses to create a safer working environment in which the likelihood and impact of a workplace incident, such as a flammable liquids fire, is actively reduced.

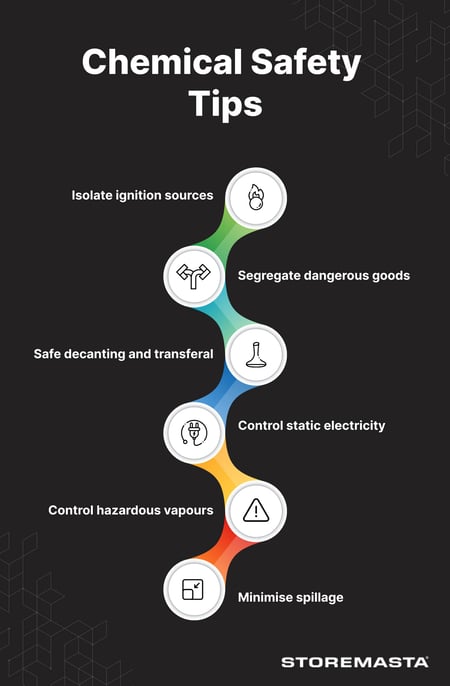

Let’s take a closer look at these 6 simple chemical safety tips now:

Tip #1. Isolating Ignition Sources

The most important rule when handling or storing Class 3 liquids is to identify and isolate ignition sources from the area. Due to the volume of flammable vapours that are emitted from open containers and drums of flammable liquids, ignition can easily occur at regular working temperatures.

Flammable liquids have a low flashpoint, which means that they can ignite, in the presence of an ignition source, at normal temperatures. For example, ethanol can produce enough vapours to ignite at 16.6°C — which is just below room temperature.

The isolation of ignition sources from all work areas that handle, transfer or store flammable liquids is essential for chemical safety.

Ignition sources can be a vast range of items, from power points to naked flames and hot surfaces. The isolation of ignition sources — and the prohibiting of ignition sources being brought into the work area by unsuspecting workers — is essential for maintaining chemical safety.

Tip #2. Not Mixing Dangerous Goods Classes

Ethanol and alcohol aren’t the only chemical substances found in wineries, breweries and distilleries. Just like many workplaces across the country, the alcohol manufacturing industry may rely upon various classes of chemicals in order to successfully run their operations.

Chemicals which may be required in a manufacturing situation could also include toxic substances and corrosive chemicals, which may be used for cleaning and sanitising applications. These applications may include such tasks as the cleaning of beer lines, the maintenance of distillery equipment, or the treatment of wastewater.

Ensuring that chemical classes are correctly segregated is a key consideration when operating any business that relies on hazardous substances. Flammable liquids are incompatible with all other classes of dangerous goods, and therefore must be properly segregated to ensure that dangerous reactions don’t occur.

Tip #3. Creating Safe Decanting and Transferal Processes

Flammable liquids can produce vapours, create chemical spillage and splash onto the skin or eyes of workers. When decanting or transferring these chemicals, make sure that equipment is compliant and suitable for use with the class of dangerous goods.

The Australian Standard for flammable liquids, AS 1940:2017, suggests that dispensing pumps or self-closing metal taps should be used to reduce these hazards.

If liquids are being transferred, always make sure that the equipment is continuously bonded to reduce the risk of static electricity causing the ignition of flammable vapours.

Tip #4. Controlling Static Electricity

If your team are working with Class 3 liquids, an incident of static electricity can turn a simple work task into a dangerous fire or explosion hazard. Therefore, having a solid understanding of how to control static charge is essential when you’re working in a winery, brewery or distillery.

Static can occur when electrical charge builds up on an object, whether that’s your skin, clothes or even your decanting equipment.

To reduce the risk of static charge in your operations, it’s important to only use compliant equipment and PPE when working with your hazardous chemicals. Conduct a risk assessment to determine if static could be created during your work processes. Then consider the substitution of materials which are likely to create charge.

Controlling static should be a primary concern when you’re working with ethanol and other Class 3 dangerous goods.

If objects create a charge, and flammable liquids are nearby, ignition of the flammable vapours can occur, resulting in fire, explosion and flashback.

Any outdoor chemical stores should also be earthed, as per the requirements of AS/NZS 3000, so that any charge (such as a lightning strike) is sent safely into the ground below the chemical store.

Tip #5. Minimising Spillage

Leaks and spills of hazardous chemicals must be contained and managed to reduce chemical risk. However, when your job is working with hazardous liquids day-in, day-out, there are many opportunities for a chemical leak or spill to occur.

Take a multi-layered approach to spill containment including set procedures, compliant handling and storage equipment, and regular reviews of chemical controls.

The safe handling, storage and transfer of hazardous chemicals is essential for chemical safety in distilleries, wineries and breweries. When conducting an onsite risk assessment of your operations, you should be able to identify spill risk in your handling, transfer and storage areas.

Solutions to contain spillage are varied and may include:

- Developing set procedures for staff to follow when handling chemicals

- Ensuring deliveries are taken by authorised staff and sent directly to bunded storage facilities

- Maintaining storage facilities so that chemical residue and spillage is cleaned up immediately

- The use of bunded handling equipment, bunded storage and safety cabinets

- Supervision when chemical decanting and transferal occurs

- Regular inspections of chemical containers, equipment and storage areas to detect damage or wear and tear which can lead to the accidental release of chemicals

Tip #6. Controlling Hazardous Vapours

The minimisation of harmful and dangerous vapours is an important step in chemical risk reduction. If hazardous vapours build-up in storage or work areas, it could result in human harm, a fire or explosion hazard, and the exceeding of legal limits as set by the workplace exposure standards.

Vapours can be easily controlled in a number of ways, including:

- Ensuring stores aren’t loaded past their capacity

- Keeping spill sumps clean and free of residue

- Keeping lids on chemical containers

- Not opening chemical packages until they’re needed

- Providing adequate natural or mechanical ventilation in work and store areas

- Monitoring harmful vapour concentrations to keep within the legal limits

Keeping Operations Safe

To learn more about working with Class 3 liquids in a safe and compliant way, why not access our helpful guide? Essential Considerations When Storing Flammable Liquids Indoors, will introduce you to our 4-step risk control methodology, IDENTIFY – ASSESS – CONTROL – SUSTAIN. This methodology can be easily applied to any workplace, including wineries, breweries and distilleries. Grab your own copy now by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.