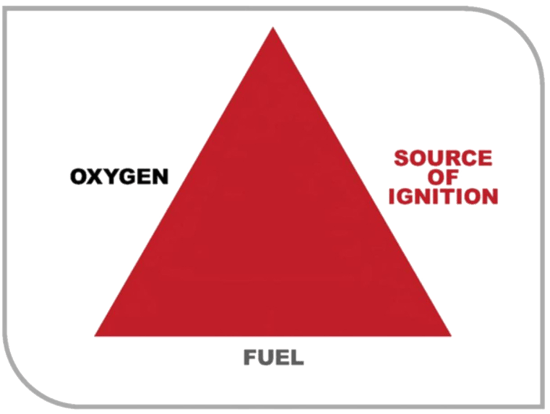

Flammable liquids are found at just about every workplace. From fuels to common cleaning agents, solvents, paints, waxes and polishes, Class 3 Flammable Liquids are commonly used chemicals that are essential for a variety of industries. However, just like with any Dangerous Goods, you must know how to reduce the risk associated with their use. When it comes to handling and storing flammable liquids, a crucial risk control measure is to correctly identify and control ignition sources in the work area to avoid serious incidences such as fire and explosion.

Identifying Ignition Sources

Let’s begin with a quick list of the different types of ignition sources to help you identify the ignition and fire hazards in your own business.

There are a vast range of ignition sources that may be present in your workplace. These may be classed as thermal, electrical, mechanical or chemical.

Ignition sources, such as power points, machinery or furnaces, may already exist in your work area — or they may be unknowingly brought into the space by staff, contractors or delivery drivers.

Identifying sources of ignition is an essential requirement for the safe storage of flammable liquids.

Identifying sources of ignition is an essential requirement for the safe storage of flammable liquids.

Possible sources of ignition include:

- Matches, cigarettes, cigarette lighters, flames, blow torches, gas appliances and heaters

- Welding and flame cutting equipment

- Static electricity generated by during fuel decanting and dispensing, clothing, or electronic equipment like mobile phones, thermostats, keyless remotes, light switches

- Hand tools, machinery and equipment that generate sparks eg, grinders

- Operating plant and machinery that generates heat: boilers, steam pipes, engines, furnaces

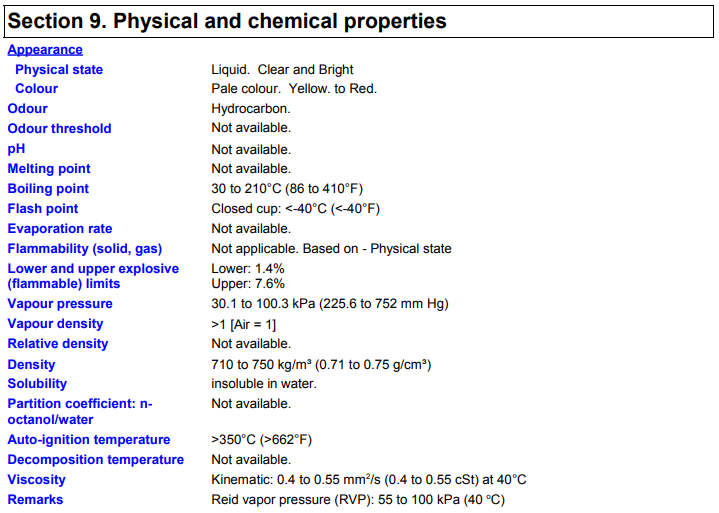

When identifying ignition sources, you must consider how they may interact with the flammable liquids held at your own worksite. That means having a comprehensive understanding of the chemical and physical properties of the liquid.

The SDS of your flammable liquids will clearly detail the flash point of your chemicals, the hazards and how you can control them.

Make sure that you always consult the Safety Data Sheets (SDSs) of your flammable liquids for known hazards and effective control measures.

Controlling Ignition Sources

Some of the best ways of controlling ignition sources in your workplace are simple, practical and cost-effective to implement.

We suggest key measures such as choosing a suitable location for your flammable liquids store, keeping your flammables in an impervious chemical safety cabinet, and training your staff so they understand the flash point of the chemicals they use — as well as the things that can ignite the flammable liquids.

The flash point of the flammable liquids that your business is carrying will determine how flammable the chemical is and how it should be handled and stored.

The control measures you decide to implement will be based on a risk assessment. This assessment will consider:

- The types of flammable liquids you use and store onsite

- Other Dangerous Goods that are held in your organisation

- How much direct contact the chemicals have with the people in your business

We’ll now detail 3 key risk control measures that are effective for the safe and compliant storage of flammable liquids.

Risk Control Measure 1: Use Chemical Safety Cabinets Designed For Flammables

Storing your Class 3 Flammable Liquids in a compliant safety cabinet is an excellent way of isolating the chemicals from potential ignition sources.

IMPORTANT: To reduce the risk of fire or explosion, you’re required by WHS Regulations and Australian Standard to keep ignition sources at least 3 metres away from your flammable cabinet. You must ensure that staff or contractors never store ignition sources within the cabinet.

Flammable storage cabinets are constructed from double-walled sheet steel and have a space of at least 40mm between the walls. Gaps around the doors and into the walls are sealed to prevent the entry of flames and radiant heat, and any insulation materials used during construction are non-combustible.

Compliant flammable cabinets are made from double-walled sheet steel and feature a liquid-tight spill containment sump.

Shelving inside flammable storage cabinets is always perforated to allow the free movement of air and each unit is fitted with a spill containment sump (at least 150mm deep).

Doors on safety cabinets for flammables are self-closing to ensure that the flammable liquids within the cabinet are insulated from ignition sources when packages are not being retrieved from the cabinet.

Some compliant indoor cabinets may also be designed to fit mechanical ventilation systems, which disperse the hazardous vapours which may build up within your cabinet. Outdoor flammable liquids units are specifically constructed for their work environment and offer protection against corrosion, the weather and impact damage.

Risk Control Measure 2: Isolate Your Flammable Liquids Store

Isolating your flammable liquids store away from site operations reduces the likelihood of your flammables being exposed to ignition sources. Safely storing flammable liquids also involves housing incompatible substances correctly.

For example, Class 5.1 Oxidising Agents and Class 5.2 Organic Peroxides should be completely isolated from flammables and stored in their own dedicated chemical store.

When deciding on the location of your flammable liquids store, your risk assessment must take into consideration:

- Fire segregation distances as per the Australian Standard AS 3833

- What combustible vegetation, refuse and waste materials are onsite

- The location of site boundaries; plus, any drains, creeks, ponds and waterways onsite as well as on neighbouring lands

- Other commercial buildings, administration areas, public access points, warehouses and production floors, laboratories, dispensing stations, and Dangerous Goods stores

- The quantities of flammable liquids being held and the type of fuel containers being used

- Delivery access and drop-off points

- Leak and spillage control

Ultimately the location of your flammable liquids stores will be determined by a detailed risk assessment using an industry-based methodology like our IDENTIFY - ASSESS - CONTROL - SUSTAIN approach.

To effectively determine the risk associated with flammable liquids in your workplace, you can use a risk control methodology.

To effectively determine the risk associated with flammable liquids in your workplace, you can use a risk control methodology.

Risk Control Measure 3: Train Staff and Contractors

Australian Standard AS 1940 - The storage and handling of flammable and combustible liquids requires that all personnel (employees and contractors) who handle flammable liquids must be properly trained in how to correctly manage these Dangerous Goods. The training must include details such as the properties and hazards associated with flammable liquids, as well as providing an in-depth understanding of the control measures that are in place at your workplace.

Staff training is key to controlling ignition sources and can be delivered via a mix of induction training, walkarounds, formal sessions, toolbox talks, and safety forums.

The 3 important things to remember when conducting training is to:

- Ensure staff fully understand what is expected of them when they finish the training

- Have mechanisms in place to observe and test the workers in their competencies

- Observe staff and conduct follow-up training so staff maintain knowledge

At a minimum, your training program should cover:

- Site rules (location of NO SMOKING areas, restricted areas, prohibited activities, banned personal equipment)

- Flash points of flammables used on the site (referring to Safety Data Sheets)

- Known ignition sources (static electricity, hot work, flames, plant and machinery)

- Job specific training (decanting and fuel transfer, where to carry out repairs and maintenance, banned equipment, task specific PPE)

- Deeper dive on specific hazards like static electricity (what it is, how it is generated, how to ground dispensing equipment, maximising static-free fabrics and clothing)

Training staff, supervisors and contractors to understand how to properly handle and store flammable liquids is essential for workplace health and safety.

Training staff, supervisors and contractors to understand how to properly handle and store flammable liquids is essential for workplace health and safety.

IMPORTANT: Many workplace deaths and accidents occur because staff don’t understand the flash point of the flammables they were using. It’s essential your training program outlines how climate, temperature, water and other chemicals — as well as confined spaces — can change the way flammable liquids ignite.

How Are You Controlling Ignition Sources In Your Workplace?

Would you like to learn more about controlling the hazards associated with flammable liquids at your worksite? Then download our free eBook How to Reduce the Risk of Flammable Liquids in the Workplace. Our eBook takes a deep dive into the risk management process and explains our methodology for controlling risks and maintaining a compliant workplace. Download and read our eBook today by clicking on the below image.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.

.png?width=600&height=178&name=Storemasta%20Academy%20Email%20Sig%20(1).png)