Are you working with paints, thinners and solvents? While paint tins may be a common sight at the majority of workplaces, paints can create serious risks due to their ability to ignite at low temperatures. These paint products can create fast-burning fires or even explosions, if ignition of the flammable vapours occurs. Therefore, if you’re carrying flammable paint products in your business, you may have to consider a paint storage cabinet.

Why are Paints Flammable?

Paints are manufactured from a range of substances that give the product its texture and colour. They're manufactured from a combination of chemicals including pigments, solvent, additives and resin.

The choice of resin (natural or synthetic) and solvent (water-based or chemical-based) for the paint product will determine the flammability of the substance.

Chemical-based solvents can contain acetone or alcohol, which are both recognised as Class 3 flammable liquids. A synthetic resin, such as epoxy, is also recognised as a highly flammable polymer.

Many paints are recognised as Class 3 chemicals.

Due to the properties of these ingredients, your paint products may be classed as flammable substances.

REMEMBER: Many paints, and related products, are in fact Class 3 Flammable Liquids. Even small quantities of dangerous goods, including just a few drums of paint, can create both physical and financial hazard for your organisation. These are in addition to the human harm caused by the chemical liquid and the resulting vapours.

Do All Paints Pose a Risk?

While the majority of these everyday products may be recognised as Class 3, there are other paint products that don't pose a fire risk. Many oil-based paints are regarded as Class 3 dangerous goods, however, most acrylic paints don't present this hazard.

So, how do you know if your paints, solvents, thinners and other products are in fact classed as flammable liquids?

As with any hazardous chemical or dangerous goods, you must read the safety data sheet (SDS) for each paint product to accurately determine the handling and storage practices for your paints. This also applies to other essential products that you may be using, such as your thinners and solvents.

The first step is to identify paint products as per the safety data sheet.

REMEMBER: The Australian Standard for flammable liquids 1940 explains that flammable liquids are liquids, or mixtures of liquids, or liquids containing solids in solution or suspension (such as paints, lacquers, varnishes etc.) which give off a flammable vapour at a flash point of no more than 60°C.

Understanding Flammable and Combustible Liquids

While very similar, flammable and combustible liquids are defined by their flash point. The flashpoint of a substance is the lowest temperature at which the chemical can ignite in the presence of an ignition source.

Flammable liquids can ignite at normal working temperature, whereas combustible liquids are recognised as less volatile substances with a higher flashpoint. Flammable liquids have a flash point below 60°C, while combustible liquids have a flashpoint over 60°C.

To determine the need for flammable liquid storage cabinets in your workplace, we highly recommend that you first go through the steps of a risk assessment.

Identifying your products by checking the individual safety data sheet for each product, allows you to assess the properties of the chemical as well as the hazards that each product poses.

REMEMBER: A risk assessment is an important step in chemical safety, allowing your business to identify chemicals, assess the risk, then work to control and sustain the measures to reduce the likelihood of hazardous incidents.

The risk assessment process will also allow your team to properly assess all risks at your site, including incompatibilities with other dangerous goods and other chemical hazards.

The identification of your paints is essential for site safety. Afterall, you can’t properly control and sustain a risk if you’re not aware of the properties and hazards associated with all the chemical products that you have onsite.

REMEMBER: You can learn more about our 4-step risk control methodology by reading our popular blog, Using a Risk Management Methodology to Manage Risks.

Dangerous Goods Class and Packing Group

In addition to determining the chemical properties and dangerous goods class of your paints, it’s important to check the packing group. The packing group will affect how your products are classed, and whether they are recognised as falling into the minor storage category.

A packing group is the classing of substances by the degree of danger that they present. The Roman numerals I, II and III represent the level of danger associated with each packing group. For flammable liquids, packing group I represents substances with a high danger, packing group II is for liquids that present medium danger, and packing group III is assigned to substances with low danger.

Many paints, varnishes, enamels and other paint products are recognised as packing group III chemicals. This packing group is important in determining your paint storage cabinet needs, as minor storage quantities are allowed if your products fall within a specific range.

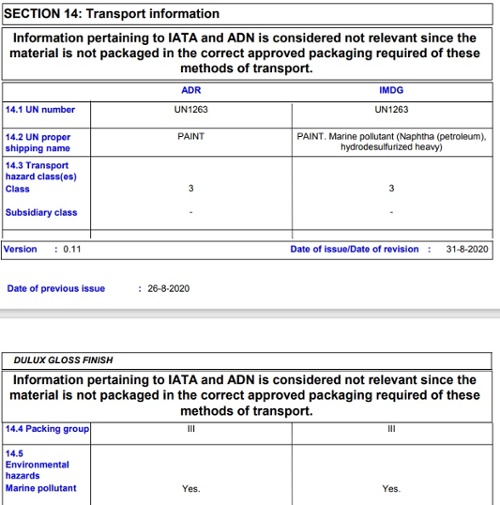

Below is an example of a gloss paint safety data sheet, that explains the packing group and hazards associated with the substance. As you can see, this is classed as a flammable liquid with packing group III.

The packing group is particularly helpful when trying to figure out if the quantities of flammable chemicals that you have onsite will classify as ‘minor storage’.

Minor Storage

Minor storage is, in the simplest of terms, a smaller amount of chemicals at your worksite. Larger quantities may be classed as package quantities, or bulk quantities of dangerous goods.

If your paints (and other products) are classed as minor storage, you do not necessarily require the installation of paint storage cabinets.

The Standard explains that:

Minor storage may exist as a part of a premises or complex in which no other flammable or combustible liquids exist, or may be part of a premises whose function is to use flammable or combustible liquids in processes or storage.

The quantities for minor storage of flammable liquids pertain to the packing group of the substance.

There are also additional requirements that relate to minor storage, in order for it to be classed as such. These may include the separation of multiple minor stores, separation between minor storage and other chemical stores, minor storage on open land, on construction sites, and using polyethylene or composite storage tanks for minor storage.

A small excerpt from Table 2.1 for minor storage quantities (AS 1940) is detailed below:

| Location | Flammable Liquid PG III |

| Educational establishments (excluding labs) | 10 L per 50 m2 of floor space |

| Laboratories | 100 L per 50 m2 of floor space |

| Commercial buildings | 25 L per 50 m2 of floor space, but 25 L for any tenancy less than 50 m2 area |

| Hospitals - indoors | 25 L per 50 m2 of floor space |

| Factories, workshops - indoors | 1 L per 1 m2 of floor space with no more than 500 L in any 500 m2 area |

| Service stations - indoors | 1250 L total in tanks or packages |

| Construction sites | 5000 L |

Additional Precautions for Storage of Flammables

If you have determined that the quantities of your paints, solvents and thinners are within the requirements for minor storage, you must still adhere to the additional precautions for minor storage.

While these are extensive and highly detailed, here is a brief summary of some key points:

- Control of ignition source – to eliminate risk of fire or explosion

- Location of minor storage – with regard to location within buildings, so it doesn’t negatively affect safety and emergency operations

- The control of flammable vapours and spillage – to reduce risk of ignition with open tins, leaks and spills

- Ventilation – to prevent human harm, as well as physical damage caused by flammable vapours

IMPORTANT: If you have identified your goods as flammable liquids, then you can refer to the Australian Standard 1940 for full details on how to handle and store these dangerous goods.

Flammable Liquid Storage Cabinets for Package Storage

When flammable liquids ignite, they can cause destruction to the business itself, as well as the surrounding area, local environment and people who are in or near the site of the incident.

As with any type of dangerous goods, the more flammable liquids that you're carrying, the greater the risk.

For many painting contractors and businesses, the storage of paints, thinners and epoxies is just part of normal operations. However, there are several steps that you need to take to ensure that you're reducing the risk of flammable liquids becoming a fire or explosion hazard. One of the most important is choosing storage in a compliant paint cabinet that meets all requirements of the Australian Standards.

Flammable liquid cabinets are designed to reduce the likelihood and impact of a fire or explosion, through the containment of leaks, spills and flammable vapours.

Features of a Flammable Storage Cabinet That Minimise Risk

Key features of a Storemasta paint storage cabinet include:

- Spill containment sump to safely contain all flammable liquid spills

- Heat barrier to slow the affects of a workplace fire on the contents of the cabinet; also allowing staff a 10 minute window to escape or action firefighting procedures

- Automatic door closing system, so the doors remain tightly shut at all times

- Double-walled sheet steel construction for protection of the contents, as well as providing a non-combustible storage solution for the flammables

- Self-closing, close fitting doors that assist with vapour and spill containment

- Built in flash arrestors, and vent openings, so mechanical ventilation systems may be installed if required

IMPORTANT: Never store paints with incompatible substances, or in conditions where there is direct sunlight or excessive heat. Be careful to contain and clean-up any leaks or spills, as fires, flashback and explosions can occur when flammable vapours escape into a workplace.

Storing Paint Safely

While many of us will have a few tins of paint gathering dust in our shed or garage, any organisation that's carrying flammable liquids has an obligation to ensure a safe workplace that's free of work health and safety hazards. And that means applying the correct and compliant measures to create safe handling and storage procedures for all of your onsite dangerous goods and hazardous chemicals. Whether you’re a sole trader, a large painting company or an organisation that uses and stores paint, you may need to consider the installation of a paint storage cabinet if your substances are recognised as flammable liquids.

However, a quick check of your safety data sheet for each paint product will help you determine the dangerous goods class, as well as the packing group of your substance. If your quantities of flammable liquids exceed those of minor storage, then you’ll require a paint storage cabinet to protect your people, property and environment from flammable vapours and the risk of ignition. To learn more about safely storing Class 3 in your workplace, grab a copy of our FREE guide.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.