When you’re carrying any type of corrosives, one of the most common queries is ‘Can Class 8 acids and alkalis be stored together?’ While some classes of dangerous goods may be stored within the same storage cabinet or chemical storage container, it’s not quite the case with Class 8 chemicals. In this post, we look at the hazards associated with acids and alkalis and highlight the control measures required to keep them safe in the workplace.

Corrosive Chemical Hazards

To start with, what are the hazards associated with corrosive acids and alkalis?

As Class 8 Dangerous Goods, corrosive substances pose a range to the workplaces that handle and store them. Acids and alkalis can create different risks, so we’ll look more loosely at those specific hazards in the next section of our blog.

Acids

As the name suggests, acids are a type of chemical within the Class 8 category that have acidic properties.

With a pH level that is less than 7, these chemicals have the ability to attack a range of materials, including human tissue and metal. How corrosive an acid is depends on the concentration of H3O+ ions in the solution. Acids that feature a higher concentration will be able to corrode materials such as metal and stone.

Class 8 acids can attack human tissue and other materials including metal.

Acids may be used in a variety of industrial, medical and commercial applications including:

- Production of phosphate and sulphate fertilizers (sulphuric acid)

- Manufacturing of some plastics and dyes (nitric acid)

- Hair dyes (chromic acid)

- Component of lead storage batteries (sulphuric acid)

The key hazards associated with corrosive acids include toxicity through inhalation, skin corrosion and eye damage. Acids can be fatal if inhaled, ingested or staff are exposed to the vapours for prolonged or repeated periods. Acute and chronic illnesses may occur when handing and storing acids without using the correct precautionary measures.

If there is a spill of corrosive acids into drains, the workplace or the natural environment, aquatic toxicity, as well as the corrosion of metals (vehicles, equipment, property etc.) are also key areas of concern.

REMEMBER: The pH level of a corrosive substance is an indication of how corrosive it is. Substances with very low or high pH levels are regarded as highly corrosive chemicals.

Alkalis

While not all corrosive bases are classed as alkalis, all alkalis are categorised as bases. Regarded as a strong corrosive base, this Class 8 substance is used for a range of purposes including the production of:

- Paper

- Glass

- Soap

- Shampoo

- Detergents

- Toothpaste

- Bicarbonate of soda

- Various metals and chemical products

Alkalis are soluble substances which have a pH level greater than 7. While bases that aren’t alkali can neutralise corrosive acids, alkalis release OH– ions and accept a proton. Sodium hydroxide and potassium hydroxide being some of the most commonly used alkali substances.

Alkalis are used in the production of a wide range of household products, including shampoo, soap, detergent and toothpaste.

Hazards associated with this type of corrosive base, may include skin burns, eye damage or irritation and respiratory issues if inhaled. Great care must be taken to avoid contact with the skin, eyes and clothing of workers. Ventilation is also important to reduce the likelihood of injury from accidental inhalation of vapours.

REMEMBER: Each alkali or acid product will have a specific set of hazards. Refer to the Safety Data Sheet to learn more about hazards, first aid measures, and handling and storage practices.

Can Acids and Alkalis Be Stored In The Same Store?

When storing any type of dangerous goods or hazardous chemical, it’s important to refer to the SDS to determine the compatibility of your product with other chemicals that you may have onsite.

While having dedicated corrosive storage cabinets or outdoor storage containers for each chemical class if the recommended storage solution, there are some specific requirements for the storage of Class 8 substances.

Acids and bases, as well as acids and alkalis, are categorised as being chemically incompatible. This means that acids and alkalis (or any type of corrosive base) must never share the same storage space.

While mixing acids and alkalis in the correct doses can create a neutralisation reaction, the mixing of acids and alkalis in storage is not acceptable due to safety concerns about adverse chemical reactions.

Incompatibility of Acids and Alkalis

Corrosive acids and alkalis can spark dangerous chemical reactions if they are stored in the same facility. It’s standard practice to always segregate acids and bases. This is due to the chemical hazards which can occur due to the incompatibility of these types of chemicals.

Safe Work Australia’s Model Code of Practice: Managing risks of hazardous chemicals in the workplace, explains that:

Acids should never be stored with alkaline chemicals due to the potential for harmful reactions. Some reactions of acids and alkaline chemicals can be highly exothermic and rapidly generate large amounts of gas, causing an explosion risk.

In addition to this guidance, the dangerous goods segregation guide explains that Class 8 Dangerous Goods may be incompatible or react dangerously with each other. Therefore, the SDS of each Class 8 product must be studied before substances are placed within the same corrosive store.

IMPORTANT: When storing Class 8 chemicals, you must segregate acids and bases, including alkali substances. If acids and any type of corrosive base mix, they may produce dangerous reactions which can cause damage to humans, property and the surrounding environment.

Class 8 Storage

Depending on the pH level of your corrosive substances and the guidelines for storage contained in the SDS, you may require a steel or poly corrosive cabinet.

Highly corrosive substances (with very low or high pH levels) require a cabinet that can withstand the emission of corrosive vapours. Poly cabinets – otherwise known as polyethylene cabinets – are constructed from HDPE, which is the purest form of polyethylene. This material is resistant to corrosion, thereby providing a secure and durable storage solution for your highly corrosive chemicals.

If your chemical products are not highly corrosive, they may be stored in a corrosive substance storage cabinet that’s constructed from metal.

The most suitable metal for safety cabinet construction is double-walled sheet steel. The corrosive cabinet should be equipped with PVC drip trays and a lined spill containment sump, to prevent chemical attack in the event of leaks and spills.

Segregation Within Class 8 Cabinets

While we’ve mentioned the need for the segregation of acids and bases, there are some types of dangerous goods storage equipment that allow for segregation of Class 8 substances — within the same cabinet.

However, make sure your equipment meets the requirements of the Australian Standards to ensure that it is providing adequate protection from the chemical hazards associated with the storage of corrosives.

Some larger chemical cabinets offer segregation (for acids and bases) within the same store. The segregation is made possible by the construction of separate storage facilities within the store (through the installation of a segregation barrier). Due to the hazards associated with leaks and spillage, the equipment must also be manufactured with separate spill containment sumps, to avoid the chemicals mixing during the storage process.

Some larger polyethylene corrosive cabinets may be equipped with segregation features.

Keep in mind that this is not always a standard feature, so check with your supplier or manufacturer to determine the exact features of your Class 8 cabinet.

IMPORTANT: Our polyethylene corrosive indoor cabinets (100L and larger) contain a segregation barrier and segregated sump. Please enquire with our Dangerous Goods Storage Specialists to learn more about these risk control solutions.

Understanding How To Segregate Class 8 Chemicals

However you choose to store your acids and bases, you must always ensure that your corrosive acids and alkalis are kept separated. This is to reduce the likelihood of the incompatible chemicals causing a dangerous reaction in your workplace.

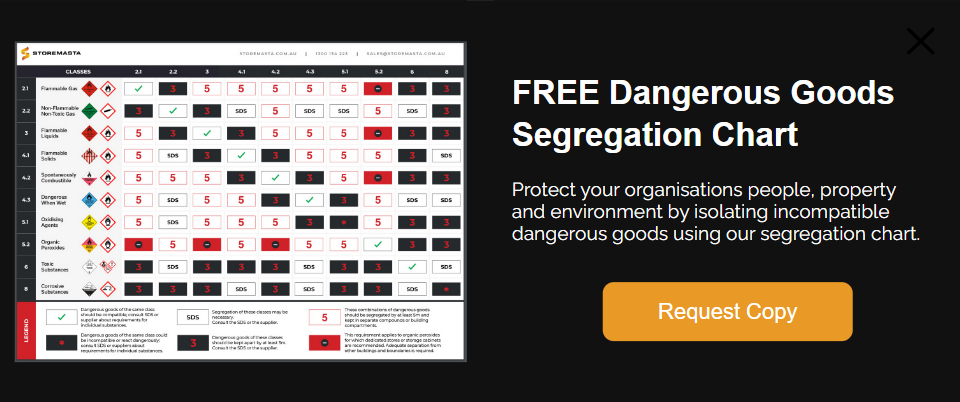

We also highly recommend conducting an onsite risk assessment of your workplace, to ensure that you’re meeting the required segregation requirements for all of your hazardous chemicals. To find out more about the safe and compliant storage of your dangerous goods and hazardous substances, why not access our free chart which details the requirements for dangerous goods segregation.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.