Acids are defined as highly corrosive chemicals that have a pH level below 7. As they are highly corrosive chemicals, acids have the ability to dissolve human flesh and destroy materials, including metal and stone. Acids will neutralise alkalis, they can turn blue litmus paper red, and they also taste sour (not that you should ever try to taste them!). In fact, the word acid originated from the Latin word acidus/acēre, which means sour. In this post, we’ll be looking more closely at acids and the risks they pose in the workplace. We’ll also be offering some helpful tips to ensure you can store acids in a safe, compliant manner.

What are Acids?

Acids can exist in several forms. They can be pure substances, such as solids, liquids or gases. Acids can also be found as an aqueous solution. Acids that are used in industry are normally aqueous solutions.

Some of the commonly used acids include:

- Hydrochloric acid

- Sulfuric acid

- Acetic acid

- Citric acid

The Risks Associated With Acids

The highly corrosive nature of acids makes them extremely dangerous — with risk to both human health and the destruction of vehicles, equipment and property.

The extent of damage to body tissue from acid burns depends on the concentration of the acid and length of exposure. If acids come into contact with your skin, they will cause severe burns and destroy body tissue.

Acids can also dissolve heavy duty materials such as steel, concrete and stone. This poses a wide range of issues for the workplaces that carry these corrosive substances.

If acidic substances such as sulfuric acid came into contact with a machine which is constructed of metal, the acid would cause the machine to corrode. If this corrosion is not controlled, the machine would cease to function, which could cost your organisation money and downtime.

To prevent harm to human health and damage to business property, acids must be stored in a safe and compliant manner. The requirements for acid storage are outlined in the next section of our post.

Acid Storage Requirements

To ensure that your organisation is protected from the risks associated with acids, all acids must be stored in full conformance to the requirements outlined in the Australian Standards.

The Australian Standard that outlines the requirements for the storage of corrosive substances including acids is AS 3780-2008 - The storage and handling of corrosive substances. This Standard outlines the different requirements for indoor storage and outdoor storage of corrosive substances, including acids.

Acids can be safely stored indoors using a compliant indoor safety cabinet. Compliant outdoor storage can be achieved with a chemical storage container that has been manufactured in full conformance to AS 3780.

The ability of an acid to corrode another substance depends on the concentration of H3O+ ions in the aqueous solution. Acids with a higher concentration have a stronger ability to corrode other substances such as metal and stone. Because the strength of acids vary, there are indoor storage solutions available for both weak acids and strong acids.

How To Store Acid

No matter whether acid storage cabinets have been designed for the storage of weak or strong acids, they must always meet the minimum requirements outlined in AS 3780.

These requirements include:

- The cabinets must be provided with self-closing, close-fitting doors that are held shut by catches at two or more points. The doors must not open inwards and they must be capable of being opened from within the cabinet.

- The cabinet must have a liquid tight sump that is at least 150mm deep and capable of containing at least 25% of the cabinet’s storage capacity.

- The shelves within the cabinet must allow for free air-movement within the cabinet.

We’ll now go into further detail about the differences between the storage of weak acids and the storage of strong, highly corrosive acids.

IMPORTANT: Consult your product’s Safety Data Sheet to determine the acidity of your chemical. A strong acid would have a pH level from 0-3 and a weak acid will have a pH level from 3-7.

Storage of Weak Acids

Corrosive storage cabinets that are designed and constructed to store weak acids. They generally feature a metal construction, such as coated steel. To give acid cabinets extra corrosion protection, PVC spill trays and sump liners are placed on the shelves and within the sump of the acid storage cabinets.

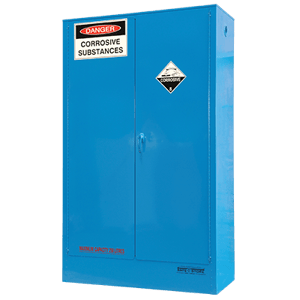

An example of an acid storage cabinet that can be used for the storage of weak acids is shown below:

Storage of Strong Acids

When storing strong acids, you must use a cabinet that will withstand the highly corrosive properties of strong acids. Cabinets used for the storage of strong acids are constructed from high-density polyethylene.

High density polyethylene is corrosive resistant, and it won’t break down when exposed to strong acids. Cabinets used for the storage of strong acids shouldn’t have any components such as door-closers or latches that are constructed from metal.

An example of a polyethylene corrosive storage cabinet is shown below:

Outdoor Storage of Acids

To reduce the risks associated with corrosive substances, large quantities of acids must be stored outdoors.

In Section 4.6.3 of AS 3780, the Standard explains the maximum quantity of corrosive substances that can be stored in an indoor corrosive storage cabinet. The requirements state that corrosive substances must not exceed 1000L, with no more than 250 kg (or L) of Packing Group II and no more than 50 kg (or L) of Packing Group I.

Larger quantities of corrosive substances can be safely stored outdoors using a chemical storage container that has been manufactured in full conformance to AS 3780.

The design requirements for acid storage containers include:

- The materials used for the construction of outdoor acid storage containers must be corrosive resistant, or coated with a corrosive resistant lining

- The acid storage container must have sufficient natural ventilation to keep the concentration of corrosive vapours below the workplace exposure standards.

- The container must have a spill containment sump that is capable of holding at least 25% of the storage capacity of the container or the capacity of the largest container, whichever is greater. In all instances, the spill containment sump doesn’t need to be greater than 5000L.

An example of an outdoor acid storage container is shown below:

Do You Know How To Store Acid Safely?

As we’ve highlighted in our post, acids are highly corrosive chemicals which can potentially cause harm to staff and property. To reduce the risk of harm to people and property, acids must be stored in a compliant manner that meets the detailed requirements of the Australian Standard AS 3780. This Standard explains the various requirements for indoor storage and outdoor storage of corrosive substances, so that workplaces can achieve and maintain compliance.

To ensure that you comply with legislation, it is important that you first identify and assess your specific acid storage situation before implementing any solutions. If you’d like more information on how to manage the risks associated with hazardous chemicals, download our FREE eBook by clicking on the image below. We’ll introduce you to our 4-step risk management methodology which can be easily applied to your acid stores.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.