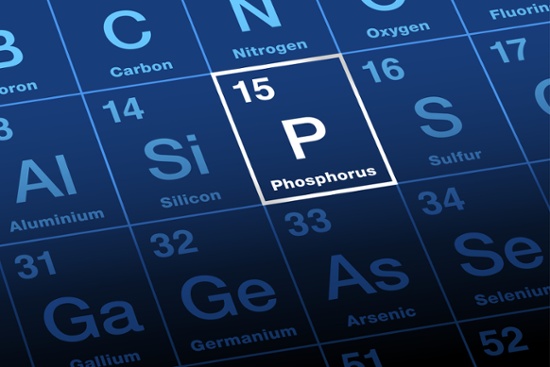

Are you working with any spontaneously combustible chemicals, such as white phosphorus or aluminium alkyls? These dangerous substances require specific storage conditions in order to keep your people and property safe. In this post, we’ll explore spontaneously combustible substances and offer some tips on how you can protect your organisation from the risk of combustion.

Are Spontaneously Combustible Substances Dangerous Goods?

As the name suggests, spontaneously combustible chemicals are those which can spontaneously combust when they are exposed to oxygen (ie. air).

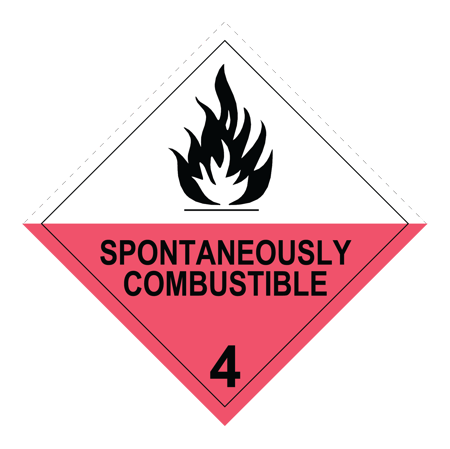

Spontaneously combustible substances are recognised as Class 4.2 substances that fall within the Class 4 Dangerous Goods category. The chemical property of the substance that determine this dangerous goods classification is that the product can ignite when in contact with air within just 5 minutes.

The Australian Dangerous Goods Code – commonly referred to as the ADG Code – explains the classification of these goods:

Class 4 Dangerous Goods are divided into 3 divisions:

- DIVISION 4.1 - FLAMMABLE SOLIDS, SELF-REACTIVE SUBSTANCES, SOLID DESENSITISED EXPLOSIVES AND POLYMERIZING SUBSTANCES (otherwise known as Flammable Solids)

- DIVISION 4.2 - SUBSTANCES LIABLE TO SPONTANEOUS COMBUSTION (referred to as Spontaneously Combustible)

- DIVISION 4.3 - SUBSTANCES WHICH IN CONTACT WITH WATER EMIT FLAMMABLE GASES (known as Dangerous When Wet)

REMEMBER: All dangerous goods have unique physical and chemical properties that must be controlled to reduce the risks associated with the substance. Always refer to the safety data sheet (SDS) of your chemicals, as well as the relevant Australian Standard, to develop safe handling and storage procedures for your dangerous goods.

Defining Division 4.2 Substances

In Section 2.4.3.1.1 of the ADG Code, we find the definition of Division 4.2 substances.

Substances liable to spontaneous combustion are defined as:

- Pyrophoric substances: substances, liquid, solid or mixtures, that will ignite (even in small quantities) within 5 minutes of coming into contact with air. These pyrophoric substances are the most liable to spontaneous combustion.

- Self-heating substances: these substances (other than pyrophoric substances) are liable to self-heating. Self-heating substances will ignite only when in large amounts (kilos) and after long periods of time (hours or days).

Substances, including White Phosphorus, are spontaneously combustible chemicals.

Risks Associated with Division 4.2 Chemicals

Spontaneous Combustible substances require strict controls to mitigate the devastating effects that combustion can pose to your organisation.

From human harm and fatalities to the destruction of property and environmental damage, spontaneous combustion of Division 4.2 substances is a risk that requires dedicated handling and storage practices.

Risks include:

- Human harm through routes of exposure

- Fire and explosion risk

- Toxic gas exposure during fire

- Airborne contaminants if non-compliant storage and handling practices

- Chemical spill risk

- Reactions with incompatible dangerous goods

Packing Group

The degree of risk that the substances can pose is largely determined by the packing group of the chemical product.

One of three packing groups into which dangerous goods are designated in the ADG Code, in decreasing order of hazard.

Packing groups are designated by the Roman numerals:

- ‘I’ (indicating substances with high danger)

- ‘II’ (substances posing medium danger)

- ‘III’ (considered low danger)

Some examples of packing groups for spontaneously combustible substances include:

- Packing group I: pyrophoric solid organic, pyrophoric liquid inorganic, hafnium powder dry.

- Packing group II: self-heating solid organic, organic pigments self-heating, thiourea dioxide, p-nitrodosodi-methylaniline.

- Packing group III: carbon activated, copra, xanthates, zirconium powder dry.

Class 4 dangerous goods pose a risk to staff, property and the environment if they are not handled and stored in a careful and compliant manner.

General Considerations When Introducing Class 4 DG

When considering Class 4 Dangerous Goods for your workplace, you will have to factor in a range of risks.

- Hazard identification and risk assessment

- Type and quantity of Class 4 Spontaneously Combustible substances

- Exclusion of ignition and heat sources, including equipment

- Other dangerous goods at your site

- Development of technical, operational, organisational and emergency procedures for your premises

- Ease of access to storage and handling sites, with consideration to evacuation during a fire or explosion

- Surrounding environment including protected and public places

REMEMBER: Your safety data sheet will provide you with the details of your chemicals, including the dangerous goods class or division and the packing group assigned to your substances.

Class 4 Storage

When storing any type of Class 4 dangerous goods, there are a limited number of chemical stores that are applicable under the requirements of the Australian Standards.

AS NZS 5026 – The storage and handling of Class 4 dangerous goods outlines the various store types that are suitable for spontaneously combustible substances or other Class 4 chemicals.

Package store options may include:

- Free-standing roofed building

- Room or roofed area external to another building, but attached to external wall

- Room or area within a building, with one wall that’s attached to external wall of building

- If appropriate, an open air storage facility

- Fire-resistant storage cabinet

REMEMBER: Storemasta manufactures compliant chemical storage cabinets that meet the requirements of the relevant Australian Standard. Spontaneously combustible substances can be safely kept in a Class 4.2 chemical storage cabinet.

Class 4 Storage Cabinets

There are a range of requirements that apply when choosing cabinet storage for your spontaneously combustible substances.

You must ensure your chemical storage cabinets are suitable for the dangerous goods that you’re storing.

These requirements include, but are not limited to:

- Leaks must be directed into the lower compound of the storage cabinet.

- The compound must be liquid-tight and at least 150mm deep; it must be capable of containing at least the contents of the largest container.

- Shelving needs to be perforated for free air movement.

- Storage cabinet doors must be self-closing and close-fitting.

- Doors must be held shut by a friction-type or magnetic-type lock which will release if there is a build-up of pressure inside the cabinet.

- Gaps around doors and into spaces between walls must be sealed to prevent spread of flame or heat radiation.

- Walls, floor, door and roof of storage cabinet must be double-walled sheet steel at least .75mm thick.

- An airspace space of 40mm or more must be provided within walls.

- Components that are essential for structural integrity must not melt at temperatures less than 850°C.

Cabinet Signage Requirements

Class 4 cabinets must also be marked with a variety of signs to maintain compliance and safety.

These chemical storage cabinets must feature:

- ‘NO SMOKING, NO IGNITION SOURCES WITHIN 3m’ hazard signage, with lettering at least 50mm high

- Maximum storage capacity of the cabinet

- Name and address of the manufacturer

- Spontaneously Combustible Class 4.2 label, at least 250mm nominal length

Cabinet markings alert staff and visitors to chemical hazards in the work area.

Class 4 Ventilation of Cabinets

If a toxic or flammable gas could be emitted from the packages, compliant mechanical ventilation should be installed.

The ventilation ducting must be designed to prevent back-pressure, with the ducting directed away from:

- Ignition sources, such as flames, sparks and heat

- Areas where people may congregate

Like to learn more about cabinet ventilation?

Exclusion of Ignition Sources

Any potential ignition source — whether it’s a hot surface, equipment that produces a spark, static electricity from workwear, or a lit cigarette — must be identified and excluded from any storage or handling areas for spontaneously combustible substances.

You’re required to exclude ignition sources from the cabinet and surrounding area by a distance of at least 3 metres.

REMEMBER: Make sure you educate your staff on how to spot an ignition source, so they don’t unknowingly bring an ignition source into the work area. It’s also essential that you provide up-to-date dangerous goods training so they can understand all the hazards associated with Class 4 dangerous goods.

Class 4 Requirements

As we’ve highlighted in this post, there are many factors to consider when working with spontaneously combustible substances. As these dangerous goods pose a great risk to your organisation and community, the first step in safety is properly identifying any hazards that may be present. By studying your safety data sheets and the Australian Standards, you can access highly detailed information that will help you maintain chemical safety in your operations. However, as we have touched on here, there are many requirements that apply to both the storing and handling of dangerous goods.

That’s why it’s so important that you start with an accurate risk assessment of your workplace. The risk assessment process will allow you to have an overall view of your workplace hazards, so you can work on identifying and controlling chemical hazards, to provide a safe environment for your team.

Access your free risk assessment template today — and take the next steps towards achieving chemical compliance.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.