When you’re storing any class of dangerous goods in the workplace, one of the most important considerations to make is how to segregate your chemicals from other incompatible substances. In circumstances that involve the storage of highly volatile chemicals, such as Class 2.1 Flammable Gases and 3 Flammable Liquids, you must consider how these substances could react and cause harm to people, property or the environment. In this blog, we’ll be unpacking the storage requirements that relate to storing flammable gases and liquids. We’ll then be answering the question, ‘Can you store flammable gases and flammable liquids together?’

Before we get started, let’s take a quick look at these dangerous goods and explain the risks associated with their storage.

What Are Flammable Gases?

Class 2.1 Flammable Gases are a subdivision of Class 2 Flammable Gases. Other gases which are included in the Class 2 category include Class 2.2 non-flammable, non-toxic gases, Class 2.2/5.1 flammable, oxidizing gases and Class 2.3 toxic gases. Unlike the other Class 2 gases, Class 2.1 Flammable Gases represent a significant risk due to the chemical’s ability to easily ignite in the presence of an ignition source.

Section 3.1.2 of the Globally Harmonised System of Classification and Labelling of Chemicals (GHS) explains that Class 2.1 Flammable Gases are gases which, at 20 °C and a standard temperature of 101.3 kPa, are ignitable — when in a mixture of 13% or less by volume in air.

This definition highlights just how flammable this type of gas can be; with the chemical capable of causing a fire or explosion if it meets a hot surface, a naked flame or any type of workplace ignition source.

Another risk associated with the storage of flammable gases is the risk of the cylinder becoming a projectile. Unrestrained gas cylinders have been known to become airborne and cause severe physical damage to staff, property and vehicles.

Some examples of flammable gases include the following commonly found substances:

- Methane

- Hydrogen

- Acetylene

- Propane

- Butane

- Ethylene

Flammable Gases, such as methane and butane, pose risks including fire, explosion and asphyxiation.

What Are Flammable Liquids?

The ADG Code provides us with a definition of flammable liquids:

“Flammable liquids are liquids, or mixtures of liquids, or liquids containing solids in solution or suspension which give off a flammable vapour at temperatures of not more than 60 °C, closed-cup test, or not more than 65.6 °C, open-cup test, normally referred to as the flash point.”

Class 3 Flammable Liquids are considered highly volatile chemicals due to their ability to ignite at temperatures lower than 60 °C. That means that if your flammable liquids could cause a fire at normal working temperatures.

Some examples of flammable liquids often found in the workplace include:

- Acetone

- Benzene

- Diethyl ether

- Petrol

- Ethanol

- Methylated spirits

The key risks associated with the storage of flammable liquids includes asphyxiation and human harm (caused by high concentrations of hazardous vapours) and fire or explosion (if vapours meet an ignition source). There is also the risk of chemical leaks and spills, due to Class 3 chemicals being in the liquid form.

Petrol, ethanol and methylated spirits are some common examples of Class 3 Flammable Liquids.

Due to these many risks, there are a range of requirements you must comply with if you want to find a safe storage solution for your flammable liquids.

In the next section of the blog, we’ll explain the requirements that relate to the storage of flammable gases — as well as highlighting the requirements for flammable liquids storage. We’ll also be detailing how these compliant storage solutions provide the necessary controls to minimise risk for businesses who carry these flammable chemical classes.

Storage Requirements for Flammable Gases

To determine the storage requirements for your cylinders of flammable gases, you should refer to the specifications laid out in the Australian Standards. The Standard that relates to the handling and storage of Class 2.1 Flammable Gases is AS 4332 – The storage and handling of gases in cylinders.

Compliant gas cylinder cages or stores must be constructed with risk control measures including:

GENERAL CONSTRUCTION

- Gas cylinder cage or store to be constructed with non-combustible construction materials.

- To feature a level base to prevent cylinder instability.

- Doors that open outwards or have a ventilated roller door which can be opened from inside.

PROJECTILE PROTECTION

- Gas cylinder restraints and chains to prevent bottles falling over or becoming projectiles.

VENTILATION

- Adequate ventilation to disperse hazardous gas leaks.

It’s generally recommended that gas cylinder cages or stores are placed outside (but not in direct sunlight) to encourage the effective dispersion of hazardous vapours. If cages or stores aren’t equipped with adequate ventilation, the risk of human harm, fire and explosion will be amplified. You should only store Class 2.1 gas cylinders indoors if your store has been built with the appropriate fire-rated construction and ventilation.

Storage Requirements For Flammable Liquids

The Standard which relates to Class 3 flammable liquids is AS 1940 – The storage and handling of flammable and combustible liquids. As one of the most comprehensive safety standards, AS 1940:2017 provides an extensive list of storage requirements that have been set out to minimise the likelihood and impact of chemical risks.

The requirements for storage that we’ll be detailing today relate to the storage of flammable liquids in safety cabinets.

To maintain compliance, flam

mable cabinets must include the following risk control features:

HEAT AND FIRE PROTECTION:

- Double-walled sheet steel for the walls, doors, floor and roof.

- At least a 40 mm thermal air gap between the cabinet walls.

- Materials critical to structural integrity shall not melt at temperatures below 850°C.

- Any gaps around doors and walls must be sealed.

- Doors should be held shut automatically by catches at 2 or more points.

CHEMICAL SPILL CONTAINMENT:

- All spills should be directed into a liquid-tight spill sump.

- The spill containment sump at least 150 mm deep.

HAZARDOUS VAPOUR DISPERSION:

- Perforated shelving for the free movement of air.

- Self-closing and close-fitting doors to contain spills and vapours.

For compliant storage of flammable liquids, choose a cabinet that’s been manufactured to meet the requirements of the Australian Standards.

Chemical Store Location Requirements

There are several key requirements that are necessary for the compliant storage of flammable gases or flammable liquids.

These include:

- Isolation from ignition sources

- Separation from protected places

- Segregation from incompatible substances

These requirements are designed to protect your people and the surrounding community from any potential risks which may be associated with the storage and handling of flammable chemicals.

Ignition sources should be isolated from both flammable gas and flammable liquids stores by a distance of at least 3 metres.

Flammable gases and liquids must be isolated from ignition sources, separated from protected places and segregated from incompatible substances.

Stores should also be separated from protected places, such as residences, schools, churches or any congested area, by a specific distance that is set out in the relevant Australian Standard.

When planning an outdoor chemical store, it’s important to take into consideration these location and separation requirements before you proceed with the installation of your flammable liquids or flammable gases store.

Segregation From Incompatible Substances

To answer the question, ‘Can you store flammable gases and flammable liquids together?’ you must not only consider the individual storage requirements for each chemical class, but you should also refer to the dangerous goods segregation requirements.

If incompatible substances are stored in the same chemical store, they could react with each other and cause a hazard such as toxic vapours or a violent chemical reaction. Therefore, when considering the storage of flammable gases and flammable liquids, you must refer to the segregation requirements for these dangerous goods classes.

When storing flammable gases and flammable liquids, you must ensure that these chemicals do not share a store. The segregation requirements for Class 2.1 Flammable Gas and Class 3 Flammable Liquids are that these dangerous goods classes must be segregated by a distance of at least 5 metres.

If these chemicals were stored in the same dangerous goods store, they could cause a severe reaction. This segregation distance is required for the safety of your people, property and environment — and is part of your legal obligations under WHS Regulations.

IMPORTANT: If your organisation is storing multiple classes of dangerous goods, make sure you refer to the segregation guide to store your chemicals safely. Follow the segregation requirements and keep incompatible dangerous goods apart from each other.

Can Flammable Gases Be Stored In A Flammable Store?

Section 3.7 of AS 1940, the Standard explains that:

“Aerosols of Divisions 2.1 and 2.2 may be stored in a store for Class 3 dangerous goods if projectile protection (e.g. cages) is provided.”

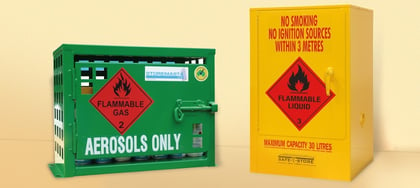

However, we suggest keeping your flammable liquids in a compliant flammable cabinet while storing your flammable gases at a safe distance, in a compliant gas cylinder cage. This ensures that both classes of dangerous goods are stored in an environment that provides safety and compliance.

REMEMBER: Always refer to the dangerous goods segregation chart — and the Safety Data Sheets for each individual product — to determine the segregation and storage requirements for your hazardous chemicals.

How Are Your Storing Your Flammable Chemicals?

Now that you’ve read our blog on how to store flammable gases and flammable liquids, we hope you can meet your compliance obligations by following the correct storage, isolation, separation and segregation guidelines. Remember, it’s very important to check the SDS of each hazardous chemical, as well as the segregation chart, to ensure that you’re handling and storing your goods in the correct way. Many classes of dangerous goods, such as flammable gases and flammable liquids, must be separated from other incompatible substances. However, storing your flammable liquids in a cabinet that’s been manufactured in full conformance with AS 1940 provides the necessary segregation controls for safe storage.

If you’d like to learn more about how to safely store your Class 3 Flammable Liquids in the workplace, why not click on the below image to access our free guide today?

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.