Emergency decontamination stations must be installed wherever workers are at considerable risk of being injured by chemicals or other hazardous materials. It’s mandatory first aid equipment under WHS Regulations. This blog walks you through the steps required for selecting plumbed emergency showers and eyewash — to help you choose the units that will best serve the unique safety and compliance needs of your worksite. As with all safety equipment installations, here at Storemasta, we recommend conducting a risk assessment before making any purchases.

If you own or operate a business undertaking in Australia you must provide (and ensure the availability of) fire protection, firefighting equipment, emergency equipment and safety equipment.

The Risk Management Approach To Selecting Plumbed Eyewash & Safety Shower

A risk management approach when choosing emergency equipment matches the equipment with the hazard, while ensuring new threats are not introduced. Here’s how it works (it’s a four-step process):

STEP 1: Identify

First you identify the presence of hazardous materials that could cause death or injury to your workers. It could be chemicals, dangerous goods or flying particles that reach the eyes.

Some situations that may require the use of a plumbed (or portable) eyewash station or shower may include exposure to:

- Hazardous chemicals

- Dangerous goods

- Airborne contaminants

- Glass, metal or other sharp objects

- Flames or hot surfaces causing burns

IMPORTANT: Need to know how many eye wash stations are required for your business? Find our more about installing eyewash stations by reading our post.

STEP 2: Assess

Next you assess the different ways the hazardous materials could injure your workers and the severity of the harm. This could range from minor discomfort to deep tissue burns — or even fatalities. You’ll look at the way workers use chemicals and other factors including personal protective equipment (PPE), and whether the work areas is indoors or outdoors.

During this assessment stage, you will also need to consider how many workers could be using the chemicals at the same time — and potentially require simultaneous emergency treatment.

We also recommend referring to previous incident and sick leave reports that have recorded chemical exposure injuries or near-misses.

IMPORTANT: Like to learn more about incident reporting? Get all the information you need about incident prevention with our popular blog post.

STEP 3: Control

Once you’ve assessed the hazards and selected the equipment for your installation, you’ll need to decide if you need any additional control measures to support the emergency equipment.

The control stage of your risk management process will involve the installation of your emergency decontamination equipment, such as plumbed eyewash stations or emergency showers.

At the very least you will require administrative controls like training programs and operating procedures. You may also need to introduce engineering controls (eg, enclosed chemical safety cabinets, drainage work, waste collection materials) to ensuring all the equipment can operate effectively and safely.

REMEMBER: While compliant engineering controls and safety precautions are necessary for site safety, it’s important to provide emergency eyewash facilities and safety showers to minimise the likelihood and impact of exposure to hazardous chemicals (such as corrosive or toxic chemicals) or foreign objects (such as glass or dust) in the workplace.

STEP 4: Sustain

Once the eyewash equipment is installed, you’ll need to train staff on how to use and maintain the emergency decontamination equipment.

To ensure ongoing compliance, your staff will need to be properly trained and supervised so that the equipment is being used and maintained in a compliant manner.

You’ll also need to review procedures to ensure the equipment remains compliant and in full working order.

At the same time, you’ll need to consider if the installation has introduced any new hazards. The sustain part of this risk management process ensures the ongoing compliance of your operations, as well as the effectiveness and safety of your plumbed eyewash stations and showers.

IMPORTANT: Sufficient flow is essential for emergency decontamination equipment. We highly recommend inspecting and activating your equipment weekly, to ensure your eyewash stations and safety showers are operating effectively.

Plumbed Vs Portable Eye Wash Station

Are you tossing up whether to install a plumbed eyewash station or a portable option? While portable eyewash stations may be appropriate for some circumstances, a plumbed eyewash station offers excellent protection against harm caused by hazardous chemicals or foreign objects which may enter the eyes of workers. Portable eyewash stations are generally used in situations where there is no option for a fixed solution — for example, a construction site without suitable onsite plumbing. Portable eye and body wash products may also be used to support the primary eyewash and shower facilities.

Depending on the risks at your site, and the types of hazardous chemicals that your team are exposed to, you may have to install a plumbed eyewash to ensure compliance. We always recommend referring to the relevant Australian Standard that is associated with the dangerous goods class of your chemicals. We also suggest a risk assessment at your site, to ensure that you’re equipped with the most suitable and compliant emergency decontamination equipment for your operations.

REMEMBER: Are you considering portable eyewash stations or plumbed units for your organisation? Talk to our Dangerous Goods Storage Consultants to find a compliant solution for your workplace.

Evaluating the Different Plumbed Eyewash Stations and Showers

When evaluating the different models of emergency eyewash and showers you will be considering the profiles of your workers and the location of each work area. Because plumbed installations require a dedicated water source, you’ll also need to consider the quality and pressure consistency of the water.

IMPORTANT: Safety showers, emergency eyewash stations and drench hoses are not interchangeable. They operate at different pressures and have limitations on the body areas they can cover, misuse could cause additional injuries.

Storemasta Combination Eyewash and Shower Unit

Combination eyewash and shower facilities are free standing units with a fixed height. They are designed for delivering flushing fluid to workers who are standing and are suitable for outdoor installations.

These units are a convenient and cost-effective way of providing emergency decontamination for a variety of industries and sites.

The versatile combination plumbed eyewash and shower can be used as:

- Eyewash Station (or)

- Safety Shower (or)

- Combination eyewash/safety shower

Floor Mounted Models

Floor mounted models are free standing and their height is fixed. They are designed for delivering flushing fluid to workers who are standing and are suitable for outdoor installations.

Storemasta floor mounted models are available as:

-

Eyewash Station (or)

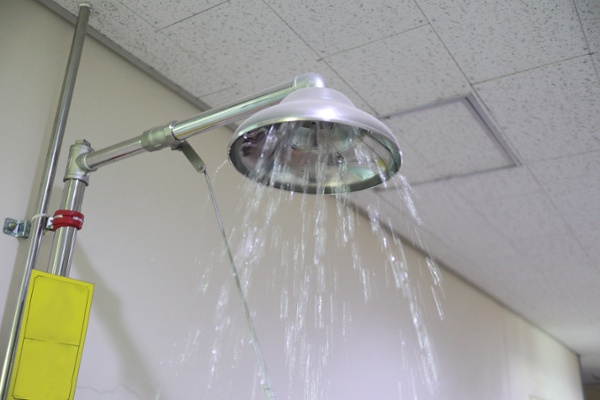

Wall Mounted Safety Shower

Wall mounted safety shower units must be attached to a solid wall but their height can be determined at the time of installation.

This deluge safety shower may be operated by a fast action stainless steel ball valve, with stainless steel valve actuator for easy and long lasting operation.

IMPORTANT: Do you understand your obligations for emergency eyewash stations? Read our popular post to find out the eyewash requirements that may apply to your workplace.

Over Sink Mounted Eyewash Station

The over sink mounted eyewash station eyewash station can be installed on the counter top or attached to a laboratory sink. These facilities are often installed in laboratories where workers are exposed to highly corrosive acids and bases.

The swivel eyewash has twin spray heads so both eyes can be flushed at the same time.

Supplementary Equipment

Supplementary equipment is designed to support a shower or eyewash station. This equipment is often used by co-workers and emergency crews when the patient is unconscious or unable to stand without assistance.

- Drench hoses are hand-held units that are designed for the head and body. They are not suitable for the eyes.

- Soft spray units are hand-held hoses designed for the eyes as they deliver a softer flow of water.

IMPORTANT: Climate is an essential consideration when selecting plumbed equipment. Extremely hot or cold environments can make it difficult to keep the water ‘tepid’. Hot water can scald workers and add to their injuries; cold water can be uncomfortable and discourage workers from flushing for the full 15-60 minutes.

Selecting Plumbed Eye Wash Stations and Safety Showers

Now you have a better understanding of the steps required in selecting suitable decontamination equipment, we encourage you to download our free eBook How to select and use compliant emergency showers and eyewash equipment. It’s a more detailed guide and the next step in chemical safety management and compliance.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.