Emergency showers are used to wash away hazardous chemicals and other contaminants from the head and body of an injured worker.

And because they are designed to drench the entire body, they are also useful for extinguishing a clothing fire and as immediate treatment for any ensuing burns. This blog looks at the different types of emergency showers available on the market and focuses on the high quality units designed and manufactured here at STOREMASTA. But this is more than a buying guide, read this blog if you want a better understanding of the risk management process.

REMEMBER: If you need an emergency shower, you may also need compliant eyewash facilities.

Assessing hazardous materials

Choosing any type of safety equipment including emergency showers should always fall within the parameters of your risk management plan. Here at STOREMASTA we recommend using a tested risk management methodology to ensure that chemicals and other hazardous materials that trigger the need for emergency decontamination facilities are properly identified, assessed, controlled and then monitored.

REMEMBER: Emergency showers and other decontamination equipment are not risk control measures, they will not eliminate a hazard or minimise any danger to your workers. They are merely first aid equipment and should supplement a range of engineering, admin and PPE controls.

Let’s take a quick look at the way a 4-step risk management methodology works and where your need for a safety shower might emerge:

-

Step 1: Identify

What chemicals and hazardous materials are on site, and where are they located? How could they injure or contaminate a worker? Identifying hazards is done by walking around the job site and observing operations. Are hazardous dusts and metal grindings generated during work processes?

Also talk to workers, read chemical Safety Data Sheets (SDSs), incident and sick leave reports. If you’ve already had a chemical accident or near-miss, this could flag the need for an emergency shower.

-

Step 2: Assess

Assess the hazards. How toxic are the chemicals? Are any highly corrosive? How are they currently being used? Are they concentrated or heavily diluted. Are workers directly exposed to flammable liquids and other fire hazards? Could workers be injured in a chemical spill? Could they be splashed while refuelling a vehicle or decanting hazardous liquids. Could someone die? How often are the chemicals used?

-

Step 3: Control

Can you eliminate these hazards? Could you completely stop using a chemical or hazardous material? One of the reasons the STOREMASTA team encourages a risk management approach to chemical hazards, is because risk management always focuses on eliminating a hazard. Eliminate the hazardous materials and maybe you won’t even need a safety shower.

If you can’t eliminate the hazard, use the Hierarchy of Control to determine the best ways of controlling hazards and minimising the danger to your workers. At this stage you’ll be checking known control measures, Safety Standards and Codes of Practice to ensure your workplace complies with WHS legislation. It is here you will determine if you need an emergency shower and other first aid equipment.

-

Step 4: Sustain

Now put in place review mechanisms, like ensuring the emergency shower you installed complies with Australian Standards and you have sufficient engineering and PPE controls. For example: staff working with hydrochloric acid are in a restricted area and wear eyes guards and gloves. The acid is stored in compliant under-bench corrosive cabinets, and a combination safety shower and eyewash station is installed close to the working area.

Once you have worked through the four steps of a risk management methodology you are in the best position to decide on the best safety shower for your worksite.

Types of emergency showers

Safety showers are either plumbed (ie, connected to a permanent water supply) or self-contained (ie, have a tank with their own supply of flushing fluid).

-

Self-contained emergency showers

Self-contained showers are useful at at remote job sites and outdoor areas that have limited access to a water supply. But, they require careful monitoring to ensure they are always operational and the tanks are full.

Plumbed emergency showers

At STOREMASTA we design and supply plumbed emergency showers because they have a dedicated water supply and suit a wider range of chemical hazards. Many strong corrosives, acids and bases require at least 30-60 minutes of flushing — and this means a lot of water. Let’s take a look at the three main units:

-

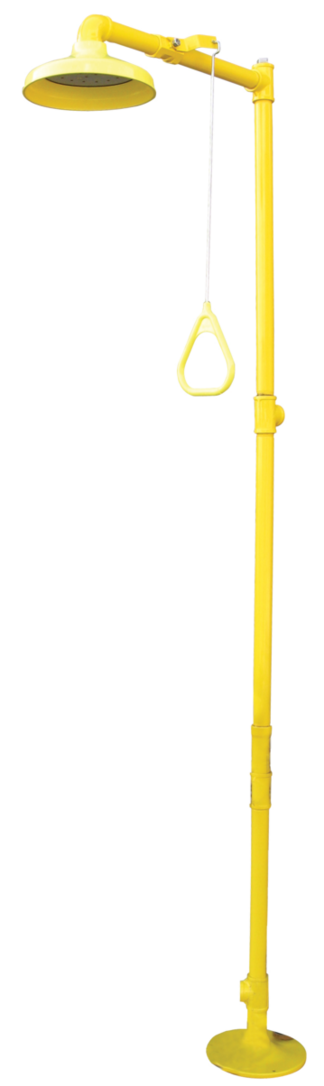

Floor mounted emergency shower

A floor mounted emergency shower is a free-standing unit ideal for an outdoor installation, but it can be easily installed anywhere there is a permanent water source. You’ll find floor mounted emergency showers in labs, warehouses and chemical decanting stations.

A single pull-chord immediately activates the unit, which will continue releasing water until manually shut down. Floor mounted showers are best for treating someone who is standing up. The height of the shower and pull chord is fixed.

-

Wall mounted emergency shower

A wall mounted emergency shower is a compact unit consisting only of a shower head and pull-down activation chord. The best part about these showers is the flexibility of installation — you can install them at any height. This is helpful if you have workers using wheelchairs or if an injured patient might find it difficult to stand.

-

Combination emergency shower/eyewash

Combination units are very popular because they have both a shower head and eyewash nozzles. The combination unit is free-standing and often used at outdoor job sites. It’s very important not to get the high pressure water from the shower head into the eyes.

IMPORTANT: Emergency showers deliver fluid at high pressure and must never be used on the eyes. If your workers are exposed to hazardous materials that could injure or contaminate the eye area, you will require dedicated eyewash equipment which delivers water at a lower (and safe) pressure.

Supplementary wash equipment

Drench hoses and other hand-held spray units are considered ‘supplementary’ wash equipment and are designed to support your existing emergency decontamination facilities. They cannot be installed as a dedicated emergency shower.

-

Drench hoses

Drench hoses are held in your hand and designed to deliver water or flushing fluid to specific areas of the body. During an emergency situation there may be two or more co-workers assisting an injured person, and the drench hose can reach areas not accessible to the fixed stream. They can also be a critical piece of equipment when the injured party is unconscious or unable to stand.

-

Hand-held spray units

Hand-held spray units are similar to drench hoses but deliver water at a much lower pressure. They are more suited to the eyes and face but are not intended as dedicated eyewash facilities. Again, they support the main unit.

IMPORTANT: It’s essential to properly train your staff so they understand how to use all the equipment in the decontamination facility during an emergency. Allow workers time to practice using each piece of equipment and include drill sessions with simulated emergency responses.

Next steps

The best way to choosing an emergency shower is to follow the 4-steps of your risk management plan, that way the equipment will always be related to the hazardous materials, chemicals and Dangerous Goods you carry at the worksite. For more information download our free eBook How to select and use compliant emergency showers and eyewash equipment — it’s our detailed guide for ensuring your emergency shower is compliant and installed correctly.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.