The rules of chemical segregation must be applied if your workplace is to effectively reduce risk. Class 5.2 Organic Peroxides and Class 3 Flammable Liquids are just two classes of dangerous goods that must be segregated in the workplace. In this post, we’ll look at the properties and risks associated with these classes of hazardous chemicals and offer guidance on how you can implement and maintain strict segregation controls.

REMEMBER: You have a responsibility under Australian WHS Regulations to keep hazardous chemicals stable on the job site and ensure they do not become unstable, decompose, or significantly increase the risk associated with another chemical.

What are the Risks Associated with Organic Peroxides?

Most organic peroxides are on industrial and manufacturing worksites. They are utilised for a wide range of applications — often involving fibreglass and resins, reinforced plastics, cosmetics, food manufacturing processes and textiles.

Examples of organic peroxides include hydrogen peroxide, methyl ethyl ketone peroxide, and benzonyl peroxide.

Is Organic Peroxide Flammable?

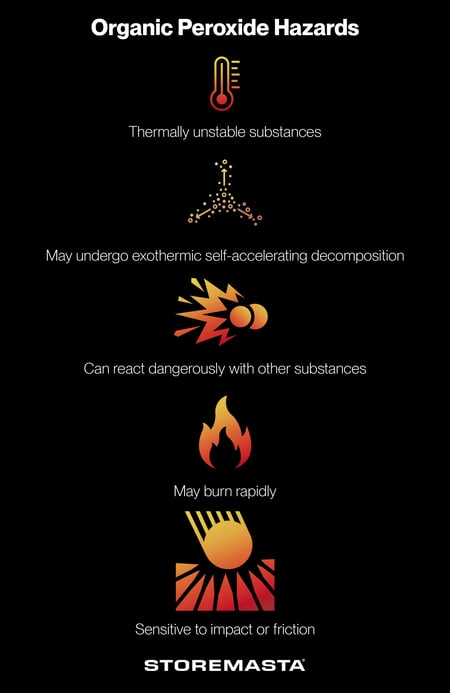

Organic peroxides have the potential to burn rapidly, creating a fire and explosion risk. They are also likely to undergo explosive decomposition and reactions with other substances. As highly flammable chemicals, any type of ignition source or incompatible substance or material must be isolated from Class 5.2 chemicals due to the risk of fire or explosion.

Exothermic Self-Accelerating Decomposition

Organic peroxides are considered a thermally unstable chemical which is prone to exothermic self-accelerating decomposition. This process occurs when the rate of peroxide decomposition produces heat at a faster speed than can be dispersed into the surrounding environment.

The temperature that the organic peroxide is handled or stored in is a key factor in the self-accelerating decomposition process. While some organic peroxides may be stored at normal temperatures, others require stores and handling facilities that are temperature controlled.

Risk of Human Harm

Not only do organic peroxides pose a risk to property and the environment through the risk of fire and explosion, but these hazardous chemicals can also cause a range of health issues.

If organic peroxides do ignite, it can result in asphyxiation due to toxic fumes, as well as health issues such as eye and skin irritation and respiratory problems.

The Importance of Segregation

When workplaces are carrying organic peroxides, they must be aware of the chemical segregation requirements for this class of dangerous good. In addition to this, if you are carrying organic peroxides and flammable liquids in your business, you must adhere to the chemical segregation guidelines. These substances are regarded as incompatible and require careful handling and storage practices to reduce risk.

Need to know more about DG segregation?

Organic Peroxides are incompatible with many dangerous goods, such as:

- Class 3 Flammable Liquids

- Class 2 Gases

- Class 4 Flammable Solids

- Class 5.1 Oxidising Agents

- Class 6 Toxic Substances

- Class 8 Corrosive Substances

- Class 9 Lithium-ion Batteries

Due to the prevalence of flammable liquids in the workplace — with commonly found substances such as petrol, acetone, kerosene and methylated spirits — we'll be focusing on the segregation requirements for organic peroxides and flammable liquids.

IMPORTANT: Key risks associated with the use and storage of organic peroxides includes fire, explosion and dangerous chemical reactions with other dangerous goods.

Storing Organic Peroxides and Flammable Liquids

With all incompatible substances must adhere to the rules of dangerous goods segregation, this post is written to assist businesses with the segregation requirements for organic peroxides and Class 3 Flammable Liquids.

Organic peroxides and flammable liquids should be isolated from each other according to the guidelines contained on the safety data sheets (SDSs) for each chemical — which is generally, at least a separation distance of at least 5 metres.

By segregating Class 5.2 and Class 3 chemicals in your workplace, you’re reducing the risk of chemical hazards that may be formed if these chemicals or their vapours, encountered one another.

Features of Organic Peroxides Cabinets

When you are looking to store organic peroxides inside a premises, you require a compliant Class 5.2 Organic Peroxides cabinet.

This model of safety cabinet must be made from double-walled sheet steel, and fitted with doors that close automatically.

The doors of a Class 5.2 cabinet release when there’s a build up of pressure within the store.

The doors of the organic peroxide safety cabinet must be held in place by a friction or magnet type lock. This is so the doors can release if pressure builds up within the cabinet. Door catches and hinges must never be made of plastic.

IMPORTANT: To learn more about the safe handling and storage of Class 5.2 Organic Peroxides you should consult the appropriate Australian Standard. The standard that relates to this class is AS 2714 - The storage and handling of organic peroxides.

Features of Flammable Cabinets

Flammable liquids cabinets are also made from double-walled sheet steel, but all materials and componentry must be able to withstand at least 850°C. This creates a heat barrier between the chemicals and any external fires.

Class 3 cabinets reduce the risk of fire, flammable vapours and chemical spills.

Cabinet doors must close automatically and create a tight fit. As the handle locks upon closing and unlocks using a key, it provides a secure and protective layer of protection against flames and heat radiation. This feature in in contrast to the organic peroxide cabinet, which offers a magnet type lock.

REMEMBER: If you’re storing flammable liquids at your workplace, you can find detailed information about handling and storage practices by consulting the Australian Standard. The standard that applies to this class is AS 1940 - The storage and handling of flammable and combustible liquids.

How To Identify Workplace Compatibility Hazards

Of course, keeping Class 5.2 Organic Peroxides and Class 3 Flammable Liquids safely isolated in indoor cabinets, installed at the correct segregation distance, is only one step to onsite chemical safety.

You also need to identify, evaluate and manage all chemical handling practices and other operational tasks where these incompatible chemicals could come in contact with one another.

Download Risk Assessment template

A chemical risk assessment for your organisation could begin like this:

Step 1 — Identify Organic Peroxides

Start with a site inspection or walk-around that identifies everywhere organic peroxides are used, stored, or handled. Organic peroxides can be very sensitive to heat and changes in temperature, so pay attention to the location of the stores. At the same time remember that ignition sources and combustibles should never be stored within 3 metres of an organic peroxide safety cabinet.

Always read your safety data sheets for each chemical product to determine the exact storage requirements, hazards and incompatabilities.

Step 2 — Identify Flammable Liquids

Next, you should consider all the flammable and combustible liquids you have onsite. This could be anything from a jerrycan of petrol or diesel, to paints, solvents, oil, grease and pesticides. Look at where flammable liquids are decanted, or where fuel-driven machines are filled or operated. Are there organic peroxides stored or handled nearby?

Look at the quantities that you are storing, and factor in the fire risk and preventative measures for the storage of these substances. See the segregation requirements in the Australian Standard AS 3833 for more information on fire segregation distances.

Step 3 — Identify Potential Contact Points

To correctly identify any potential contact points in your organisation, you must compare the two chemical lists. You should be able to accurately identify all the places where the chemicals could contact one another and cause a dangerous reaction.

You should also consider all the different ways in which these incompatible substances could come into contact with each other. This includes looking at workplace areas and procedures for delivery and chemical intake, production, warehouse and transfer, decanting, mixing, spill clean-up and disposal.

REMEMBER: One of the most common hazards is workers and external contractors carrying out maintenance work (eg welding, grinding, cutting) or bringing ignition sources near chemical safety cabinets.

How To Take Corrective Action

You’ll need to take corrective action to address all the contact hazards — your aim will be to eliminate the hazards where possible.

Corrective actions may involve:

- Housekeeping: Ensure that the site is properly maintained, so there is no build-up of combustible materials. Chemicals should be disposed of promptly and safely, with chemical spills dealt with immediately. Make sure that chemicals are put away into the cabinet or store when not in use.

- Work procedures: It’s important to implement clear work procedures for all workers and contractors who are handling chemicals, as well as workers who carry out maintenance work around the job site.

- Restricted access: To reduce risk, you can limit access to organic peroxides and flammable liquids stores and deter unauthorised entry.

- Site inductions: The implementation of site inductions ensures that everyone who enters the worksite is aware of the site rules, and chemical hazards.

- Chemical safety training: Onsite training provides essential education and skill building for staff who handle (or are exposed to) organic peroxides and flammable liquids.

- Site audits and assessments: Key safety measure to reduce risk include regular site inspections, safety audits, and risk assessments.

REMEMBER: Many organic peroxides are sensitive to temperature, so always check the safety data sheet (SDS) for any temperature-controlled storage recommendations. You are required under Australian WHS Regulations to store any temperature reactive chemical within safe temperature ranges.

How are you Storing Your Organic Peroxides and Flammable Liquids?

Businesses that carry multiple classes of dangerous goods require strict segregation controls to maintain a safe and compliant working environment. As we’ve detailed in this blog, a risk assessment is critical when your worksite carries multiple classes of dangerous goods, so you can accurately identify and control the hazards that are present.

If you’d like to learn more about reducing your risk, we recommend downloading our free eBook. Essential Considerations When Storing Flammable Liquids Indoors details the chemical risk assessment process — which you can easily apply to your own workplace. It also contains the most up-to-date chemical storage requirements and best practices. Access your free copy today to learn more about reducing risks with effective chemical segregation.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.