Are your staff working with organic peroxides? Used for a range of applications such as bleaching or maturing agents, organic peroxides include substances such as benzonyl peroxide and hydrogen peroxide. An organic peroxide is an organic compound with two oxygen atoms joined together. As a thermally unstable substance, organic peroxides the capability of causing harm to people, property and the surrounding environment. In this post, we’ll be looking at the definition of organic peroxides and explaining how they substances can impact the safety of your organisation. We’ll also be outlining the risks that they pose, as well as detailing compliant storage practices as per the Australian Standards.

Definition of an Organic Peroxide

The Australian Dangerous Goods Code provides the official definition for organic peroxides:

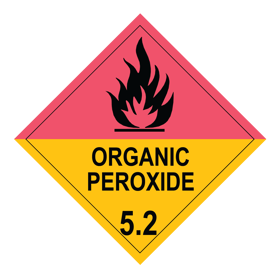

Division 5.2 Organic peroxides

Organic substances which contain the bivalent -0-0- structure and may be considered derivatives of hydrogen peroxide, where one or both of the hydrogen atoms have been replaced by organic radicals. Organic peroxides are thermally unstable substances, which may undergo exothermic self-accelerating decomposition.

In addition, they may have one or more of the following properties:

- be liable to explosive decomposition;

- burn rapidly;

- be sensitive to impact or friction;

- react dangerously with other substances;

- cause damage to the eyes.

How Do Oxidising Agents and Organic Peroxides Differ?

Oxidising agents are substances which can oxidise other substances. The oxidising process can create heat, fire and gas.

Organic peroxides are good oxidising agents, but the risks they present are not identical. Oxidising agents are non-combustible and simply provide the oxygen needed to sustain combustion. Organic peroxides, on the other hand, may combust independently. While this is a notable difference, both oxidising agents and organic peroxides should be handled and stored carefully just the same.

While found across a wide range of workplaces, organic peroxides pose specific risks to people and property.

The Risks of Organic Peroxides

Organic peroxides are, by nature, relatively unstable. They are sensitive to heat and therefore prone to decomposition by burning.

Under certain circumstances, such as high temperatures and inadequate segregation from incompatible substances, organic peroxides can ignite and cause uncontrollable fires. In some instances, exposure to excessive heat can cause decomposition and violent explosions.

There are serious risks, such as fire and explosion, if organic peroxides aren’t handled and stored in the correct way.

The risk of fire and explosion is a key concern when carrying these chemicals, but it’s not the only way that these substances can cause damage in the workplace.

Consideration must be given to the handling and storage of these chemicals to reduce the additional risks of:

- Fume or smoke emissions if substances are subjected to heat

- Spillage or run-off from fires can harm people and the environment

- The flammable, toxic, corrosive or unstable properties of the substance

- Contamination can cause organic peroxides to become highly unstable

REMEMBER: It’s essential that you refer to the Safety Data Sheet (SDS) of your particular organic peroxide products to determine the exact risks that these substances pose.

Risk To People

When organic peroxides ignite, they will burn quickly. These chemicals can cause gases that suffocate those people who are in the area of ignition.

However, even without the presence of flames, organic peroxides are often highly toxic and particularly irritating to your skin, eyes, and mucous membranes.

If you attempt to handle organic peroxides without the aid of appropriate personal protective equipment, bodily injuries will be obtained, especially if emergency eyewash stations and safety showers are not immediately available.

Risk To Property

Organic peroxides can also be very hazardous to property. Some organic peroxides are corrosive, which means that they can attack and destroy metals.

Methyl ethyl ketone peroxide (MEKP) is an organic peroxide used to incite polymerization in the production of polyester and acrylic resins. If handled incorrectly, MEKP presents an extreme risk of explosion. If MEKP comes into contact with water or moist air, it will release irritating gases.

This seemingly minor event can cause a blast that can damage equipment, machinery or an entire plant. Such an event would cause setbacks in work and huge monetary losses for the company.

Some organic peroxides present an explosion risk which can devastate operations.

Organic Peroxide Storage Standards

The Australian Standards set out the minimum requirements for compliant storage and handling of dangerous goods. These standards have been developed to promote a high level of safety for people, property and the environment where dangerous goods are stored and handled. The standard that specifies the requirements for compliant storage and handling of organic peroxides is AS 2714-2008 - The storage and handling of organic peroxides.

How to Store Organic Peroxides

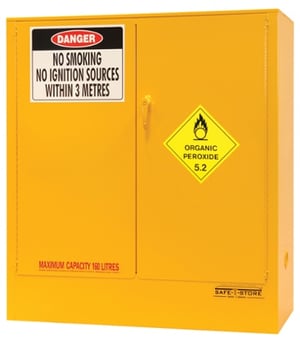

According to the Australian Standard, package stores for organic peroxides may include:

- Indoor storage cabinet

- Room or compartment located within or attached to a building

- Isolated storage area that isn't attached to or abutting any other building

Due to convenience and cost-effectiveness, businesses often choose indoor safety cabinets as a preferred method of storage for organic peroxide packages.

Heat, friction, mechanical shock or contact with incompatible substances can cause rapid and explosive decomposition in organic peroxides. However, by utilising safe and compliant organic peroxide storage cabinets that adhere to the Australian Standard AS 2714-2008, you can reduce the risk of these severe chemical reactions.

Construction

A compliant organic peroxide indoor storage cabinet would have double-walled steel construction on all sides, each wall being a minimum of 0.75mm thick. There must also be at least a 40mm space in between walls, which may be an open-air space or filled with non-combustible insulation.

Compliant organic peroxide cabinets must meet the requirements of the Australian Standards.

Doors

The door of the cabinet must be self-closing and close fitting, with either a friction or magnet type lock that can automatically release should there be a build-up of pressure inside the cabinet. Door catches and hinges should be made of metal and not plastic.

Shelving

Shelves, meanwhile, need to be constructed with a non-combustible material which is perforated for free air movement. They must also be capable of carrying the maximum load.

Spill Containment

For the cabinet to contain any potential leakage of the stored oxidising agent, the inner base of the storage cabinet must form a liquid-tight compound — at least 150mm deep.

Organic peroxide cabinets feature spill containment, perforated shelving, self-closing, close fitting doors and a thermal air barrier between the walls.

Organic peroxide cabinets feature spill containment, perforated shelving, self-closing, close fitting doors and a thermal air barrier between the walls.

Additional Considerations for Organic Peroxide Storage

Overall, a storage cabinet for organic peroxides should be sturdy and capable of protecting its contents from combustion or decomposition — whether it be gradual or sudden.

It’s also vital to ensure that the cabinet is located at least 3 metres from any ignition source, as these substances are particularly sensitive to heat.

Your Class 5.2 cabinet should come complete with compliant signage: the Organic Peroxide dangerous goods diamond and the No Smoking, No Ignition Sources within 3 Metres sign. However, it’s your duty to ensure that the signage is always clearly visible and remains in good condition.

You must ensure that your cabinet features the correct dangerous goods and hazard signage.

You must ensure that your cabinet features the correct dangerous goods and hazard signage.

When choosing a position for your cabinet, make sure it’s near an external wall of the building. It’s also important to make sure that the cabinet is not located in an area that will obstruct emergency escape routes.

If required, cabinets for organic peroxides may be equipped with mechanical ventilation that is vented to an outside atmosphere away from ignition sources and areas where staff and personnel may congregate.

You must also install two portable, dry-chemical fire extinguishers (with a rating of no less than 60B as specified in AS/NZS 1850). These should be installed in the vicinity of any organic peroxide safety cabinet.

How To Safely Store Organic Peroxide

Organic peroxides are substances which are extremely useful to a variety of businesses — but they can also be very harmful to your workplace and the wider community. When carrying any quantity of hazardous organic peroxides in your workplace, you must implement and maintain the correct storage to minimise these risks. One of the most important factors to consider is dangerous goods segregation.

If you’d like to learn more about the successful segregation of organic peroxides from other incompatible dangerous goods, click on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.