When your business is carrying flammable liquids, it’s important that you not only understand the chemical and physical properties of these substances, but how to handle and store them in a safe and compliant way. As volatile substances, Class 3 Flammable Liquids pose serious risks to organisations across the globe — with these chemicals having the potential to cause acute and chronic health issues, as well as fires and explosions. If your workplace handles these dangerous substances, keep reading this blog to get all the info you need about the requirements for Class 3 Flammable Liquid storage indoors.

What Are Flammable Liquids?

The Australian Dangerous Goods Code (ADG Code) offers this definition of flammable liquids:

“Flammable liquids are liquids, or mixtures of liquids, or liquids containing solids in solution or suspension (for example, paints, varnishes, lacquers, etc., but not including substances otherwise classified on account of their dangerous characteristics) which give off a flammable vapour at temperatures of not more than 60 °C, closed-cup test, or not more than 65.6 °C, open-cup test, normally referred to as the flash point. This class also includes:

(a) liquids offered for transport at temperatures at or above their flash point; and

(b) substances that are transported or offered for transport at elevated temperatures in a liquid state and which give off a flammable vapour at a temperature at or below the maximum transport temperature.”

As you can see in this definition, flammable liquids have a very low flash point, which means that they can easily ignite and cause destruction in the workplace.

To protect your organisation, the environment and the wider community from the risks associated with flammable liquids, you must store these chemicals in a safe, compliant manner.

Safe Storage Of Class 3 Flammable Liquids

Flammable liquids can be safely stored indoors using a flammable storage cabinet.

However, keep in mind that flammable storage cabinets must be manufactured and used in accordance with strict specifications to effectively minimise your risks. These strict specifications are set out in AS 1940:2017 - The storage and handling of flammable and combustible liquids.

Section 4.9 of the standard details the requirements for the construction and use of flammable liquids storage cabinets. Let’s have a closer look at these requirements now:

Flammable Cabinet Construction

To provide adequate protection from the risks associated with storing Class 3 dangerous goods, your flammable cabinet must have a safe and sturdy construction.

Compliant flammable liquids cabinets are constructed to meet the requirements of AS 1940:2017.

Section 4.9.2 of the standard sets out the construction requirements for flammable liquids.

These requirements for cabinet construction include:

- The walls, floor, doors and roof of the flammable cabinet must be constructed from a double walled sheet steel construction. The gap between these walls must be no less than 40mm and can be left empty or filled with a fire-resistant insulation.

- The gaps around the doors and the walls of the flammable storage cabinet shall be sealed to prevent heat radiation and the spread of flames in the event of a fire.

- The base of the cabinet shall form a liquid-tight sump of at least 150mm deep. This sump must be designed in such a way that packages are prevented from being stored in the sump. This sump will contain any spills that may occur inside the cabinet.

- The shelves inside the cabinet must be perforated to allow for free air movement inside the cabinet. The shelves should also be sturdy and capable of carrying the maximum possible load.

- The inside of the cabinet including the shelves shall be designed in such a way that any spills are directed into the sump in the base of the cabinet.

- The doors of the cabinet shall be self-closing, close-fitting and held shut automatically by catches at two or more points.

- If the doors are equipped with a device to hold the doors permanently open when the cabinet is being loaded, the doors must automatically close when the temperature exceeds 80 °C.

- Materials that are critical to the structural integrity of the cabinet must not melt at temperatures below 850 °C. Seals and gaskets are an exemption to this requirement.

Construction Requirements For Cabinets Exceeding 250L

If you’re considering a purchase of a flammable storage cabinet that’s larger than 250L, there are extra requirements to help protect your workplace from the risk of storing greater quantities of flammable liquids.

There are additional construction requirements for flammable cabinets that hold 250L or more.

The standard explains these additional requirements:

- The height of the cabinet shall not exceed 2 meters

- The external surfaces of the cabinet shall be constructed from sheet steel of at least 1 mm thick.

- The spill containment sump in the base of the cabinet shall be capable of containing at least 25% of the aggregate capacity of the cabinet or the capacity of the largest container being stored in the cabinet, whichever is greater.

Cabinet Marking

Cabinet Marking

To ensure that everyone in the workplace is aware of the potential hazards associated with the flammable liquids being stored, clear safety signage must be displayed on all indoor flammable liquids storage cabinets. The signs that are required include;

A class 3 dangerous goods label

A class 3 dangerous goods label- A sign stating “NO SMOKING NO IGNITION SOURCES WITHIN 3m”

In addition to this safety signage, the cabinet must also feature signage that includes the name and address of the manufacturer in Australia. The storage capacity of the flammable liquids cabinet should also be clearly displayed for staff to see.

Ventilation provisions

While the Australian Standard AS 1940:2017 doesn’t make ventilation of flammable storage cabinets a mandatory requirement, it provides you with the option to do so if necessary.

The key purpose of a flammable cabinet is to protect the stored chemicals from fires that are outside of the cabinet. If a ventilation system was installed on a cabinet, there’s a possibility that this protection will be reduced.

Having a mechanical ventilation system installed on your cabinet can be part of a risk control measure for your workplace.

The workplace exposure standards are crucial in determining if your indoor flammable cabinet needs a ventilation system. If the flammable liquids that are stored inside the cabinet are listed in the workplace exposure standards — and the concentration of the vapor from this liquid is greater than the maximum concentration identified — your cabinet requires ventilation.

By extracting the flammable vapours from the cabinet with a mechanical ventilation system, your cabinet will be within the workplace exposure standard limits. The safe concentration of hazardous vapours greatly reduces the risk of fire, explosion and human harm such as asphyxiation or intoxication.

Cabinet Location

To ensure that the flammable liquids stored in the workplace pose the least risk to people, property and the environment, it is important to position your cabinet in a safe location.

The location of your cabinet must meet the requirements of AS 1940:2017 to maintain safety and compliance.

When selecting a location for your Class 3 Flammable Liquids cabinet, you must:

- Ensure flammable storage cabinets aren’t positioned in a location where they will impede escape in an emergency.

- The aggregate capacity of cabinets shall not be greater than:

- 850L per 250 m2 of floor space on a ground floor area;

- 250L per 250 m2 of floor space on floors other than the ground floor.

- Each aggregate quantity (850L on ground floors and 250L on other floors) shall be separated by at least 10m.

- An indoor flammable storage cabinet can be used for outdoor storage as long as the cabinet provides adequate protection against the weather, corrosion and traffic damage.

For cabinets that have a capacity of 250L or greater, the following also applies:

- Make sure that cabinets are not placed in residential or accommodation buildings, hospitals, commercial buildings, aged care buildings or schools.

- Only locate flammable storage cabinets on floors that have direct access to the street or ground floor.

- Cabinets shall not be placed any nearer than 3m to an internal wall that is common with another room, unless the wall is constructed of concrete or masonry to ceiling height or 3m above the cabinet (whichever is less) and 3m either side of the cabinet.

Exclusion Of Ignition Sources

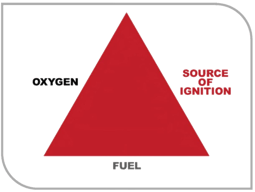

As we’ve discussed, flammable liquids can easily ignite —causing intense and rapidly burning fires, as well as devastating explosions.

Flammable liquids have a low flash point and can easily ignite if they come within 3 metres of a workplace ignition source.

Flammable liquids have a low flash point and can easily ignite if they come within 3 metres of a workplace ignition source.

To prevent these incidences from occurring, it’s important to ensure that flammable storage cabinets are always isolated from potential ignition sources.

You must ensure that:

- At all times no ignition sources shall be kept within the cabinet.

- All flammable storage cabinets shall be isolated from all ignition sources within the workplace by at least 3m (measured laterally).

- Cabinets shall also be isolated from any ignition sources by at least 1m from the nearest opening on the cabinet (measured vertically).

Operational Requirements

To ensure the maximum safety in the workplace, it’s important to use your cabinet in such a way that it doesn’t impede greater risks to your organisation.

The operational requirements for your flammable cabinet should include the following:

- People shall be prevented from entering the cabinet.

- Only one drum with a 60L capacity shall be keep in a horizontal decanting position at any one time.

- Only closed packages or those fitted with taps shall be stored within flammable storage cabinets

- Drums with a capacity greater than 60L shall not be stacked more than two high.

To maintain the safety of your cabinet, make sure that staff are trained in how to correctly stack and load the cabinet.

Are You Storing Class 3 Flammable Liquids?

Now that we’ve outlined the Class 3 Flammable Liquids storage requirements for indoors, we hope you have a good understanding of how to keep your workplace safe and compliant. By following the requirements set out in AS 1940:2017, your organisation will meet compliance obligations for flammable liquids storage —removing the risk of fire, explosion and human harm as well as financial liability due to non-compliance. For more information on how to reduce the risks associated with flammable liquids, simply download our free eBook, How To Reduce The Risk Of Flammable Liquids In The Workplace.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.