So, you’re thinking about buying a chemical cabinet for your workplace? This post will make your life a whole lot easier. From ensuring your cabinet will provide the greatest risk protection for your organisation, to making sure that your chemical storage meets your needs (now and into the future), it’s important to get the decision right the first time. But what essential steps should you take when choosing a cabinet for your business? There are a multitude of factors that will influence your decision when searching for dangerous goods storage equipment — but we’ve managed to narrow it down to a simple 6 points. Read on to find out more about the key things that you should consider when you’re buying a chemical cabinet.

1. What Chemical Are You Storing?

First and foremost, the most important factor that you should consider is the type of chemical that you’re planning to store. Every hazardous chemical has its own specific risks – and therefore, requires a particular type of safety cabinet to minimise the potential for harm.

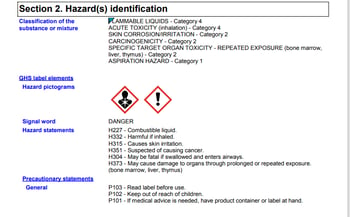

Before you start researching chemical cabinets, make sure that you refer to the Safety Data Sheet (SDS) of the chemical that you’re looking to store. Afterall, you can’t determine the correct storage for your chemical if you don’t know the dangerous goods class and properties of the product.

Your SDS will provide all the necessary details about your product, including the chemical and physical properties of your hazardous chemical. The SDS will detail all the requirements for the safe handling and storage of your product.

The first thing we suggest is to refer to the properties of your chemical as per the Safety Data Sheet.

Chemical properties (and hazards) can differ depending on the chemical manufacturer or supplier, so never assume that a product is of a particular class just because you’ve used a similar one previously. In short, get to know your SDS before you sign on the dotted line for your next cabinet.

2. How Much Are You Carrying?

You wouldn’t buy a pair of shoes that didn’t fit your feet, so why would you buy a chemical cabinet that doesn’t meet your maximum capacity requirements? OK, purchasing DG storage equipment may not be quite as simple as that, but when you’re on the lookout for a new chemical cabinet, the volume that you’re storing is a key consideration.

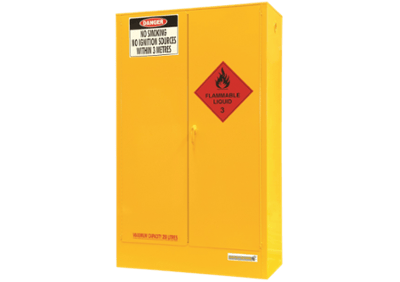

Each cabinet is manufactured to hold a specific amount of hazardous chemicals or dangerous goods. The maximum capacity of the equipment will be clearly displayed on the front of the cabinet, so there’s no confusion about the cabinet’s capacity.

Choose a cabinet that comfortably fits the amount of hazardous chemicals that you’ll be storing.

When selecting a DG storage equipment, you must always adhere to the maximum capacity requirements. Failure to do so will increase risk for the people, property and environment surrounding your operations. Choosing a cabinet that’s too small for your chemical supply may also put you in a position where you may receive a penalty for non-compliance.

Overloading safety cabinets can have serious consequences for your staff and your operations, due to an increased risk of hazardous chemical spillage and vapour emissions. Overloading cabinets will also affect the structural integrity of the equipment, with the doors unable to close properly and the shelves not being able to safely hold the weight of the stored chemicals.

3. What Types Of Packages Do You Have?

As we know, chemical products can come in all types of containers and sizes. It’s a good idea to consider what types of packages you’ll be storing in your new safety cabinet.

Most chemical cabinets offer the flexibility of fully relocatable shelving, so you can adjust the cabinet to fit the needs of your current chemical supply. However, keep in mind that different types of packages will sit differently on the shelves and take up different amounts of space.

For example, you'll be able to fit more 25kg bags into your cabinet than if you were storing multiple 20L drums. Consider the type and dimensions of your chemical packages to accurately determine the size of safety cabinet you need.

The type and dimensions of your chemical packages will affect the volume of chemicals that you can store in your safety cabinet.

When you’re looking for a cabinet for a particular work area, also consider how easy it will be for your staff to safely transfer the chemicals to and from the cabinet. If it’s a safer option to install your indoor cabinet closer to your chemical handling areas (due to heavier containers or drums), then this may influence your decision on the type of cabinet that you select.

You should also consider your emergency exits and evacuation routes to ensure that the cabinet fits within the work area without impeding escape.

DID YOU KNOW? Chemical cabinets are available in under the counter and stand-up designs? This gives your workplace the flexibility to choose a cabinet that better fits in with the layout and space of your area.

4. Will The Cabinet Still Be Suitable Over Time?

So, you’re tossing up between two compliant cabinets that will effectively reduce the risk of your onsite chemicals? Great work! You’re nearly there – but remember, dangerous goods storage is a long-term investment.

Your indoor safety cabinet will provide years (or decades) of protection for your business, if it’s used and maintained in the right way.

Therefore, when you’re selecting a cabinet for your chemical product, don’t just think about the state of your business today – think about what your storage needs may be in 1, 5 or even 10 years time.

Generally speaking, chemical safety cabinets are often more economical the larger the maximum capacity of the cabinet. So, while your 160L flammable cabinet may suit your needs right now, a 250L flammable cabinet may actually work out to be a more cost-effective choice if your business continues to grow over the foreseeable future. Think about your cabinet as a long-term storage solution, and choose the model that will comfortably fit your needs as your organisation grows.

5. Does The Cabinet Meet The Australian Standards?

When it comes to buying dangerous goods storage, you don’t want to purchase equipment that doesn’t provide adequate protection for your people, property and environment. When looking for a cabinet for your business, make sure you enquire as to whether the cabinet is made in full conformance with Australian Standards.

The Australian Standards are detailed documents which list specific requirements for the storage and handling of hazardous chemicals and dangerous goods. If your cabinet meets these strict requirements, you can feel confident that you’re buying a product that offers the best possible risk protection.

Compliant cabinets will meet the requirements of the particular Australian Standard that relates to the dangerous goods class of your chemical product. For example, if you’re storing toxic substances, your cabinet will comply with the Standard AS NZS 4452:1997.

Features for compliant toxic storage cabinets will include:

- Double walled sheet steel construction with thermic air barrier 40mm

- Liquid-tight spill containment sump 150mm deep

- Perforated steel shelving

- Self-closing, close-fitting doors held shut by catches at two points

- Dangerous goods and hazard signage

These features will act as risk control measures to:

- Contain toxic spillage and enable the safe clean-up of spills within the cabinet

- Minimise the escape of toxic vapours

- Allow for the free flow of vapours within the cabinet

- Protect packages from excessive heat or fire for a small window of time

- Prevent toxic chemical packages from being damaged through impact, misuse or theft

Make sure that the cabinet you buy is made to meet the requirements of the Australian Standards.

6. What Does The Risk Assessment Say?

We’ve saved one of the most crucial points till last. Whenever you are in the market to purchase dangerous goods handling or storage equipment, we always recommend conducting an onsite risk assessment. Your assessment will give you the in-depth understanding of your workplace to properly determine the storage needs of your organisation.

Your risk assessment should offer a complete view of your:

- Required hazardous chemical storage facilities

- Handling practices

- Level of risk posed to your business

- Operating procedures and protocols

- Hazard information and SDS

- Factors influencing risk such as incompatible substances, ignition sources

If you’re not sure where to start with a risk assessment, there are various resources and specialists that can help. Whether you enlist the help of a Dangerous Goods Consultant, or you read through one of our guides, there is plenty of valuable assistance readily available to businesses who are navigating their dangerous goods storage and compliance obligations.

IMPORTANT: You’re obligated, under WHS Regulations and Law, to provide a safe workplace that is free from hazards. Selecting, installing, using and maintaining compliant dangerous goods storage is one of the most essential steps in reducing risk in your operations.

Choosing Chemical Storage Cabinets

While we’ve listed 6 points to consider when you’re choosing a safety cabinet, there are many more factors to consider when looking at your dangerous goods storage needs. Navigating WHS Regulations and Australian Standards — as well as your own operational needs— can be a challenging and confusing task.

If you still need some assistance choosing the right chemical cabinet for your operations, we have an eBook that can help. Essential Considerations When Storing Flammable Liquids Indoors will help you determine your storage needs if you’re storing any type of Class 3 Flammable Liquids, such as petrol, kerosene, acetone or even paint. Our guide will help you select the appropriate cabinet, as well as use and maintain it to meet Australian Standards. Grab your copy of our guide today and find out how to reduce risk in your hazardous chemical storage areas.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.