An oxidizing gas is a type of compressed gas that can cause oxidation — a chemical reaction in which an element or compound loses electrons. Oxidizing gases are typically highly reactive and therefore pose a significant risk of fire or explosion.

Examples of Oxidizing Gases Used in the Workplace

Examples of oxidizing gases include oxygen, ozone, chlorine, halogen and fluorine.

These gases are often used in industrial processes such as metal fabrication, chemical production, and water treatment.

Oxygen is one type of oxidizing gas that is commonly used in the workplace.

Classification for Gases

Class 2 Gases refer to those chemicals that are compressed, liquefied or dissolved under pressure.

The Australian Dangerous Goods (ADG) Code details the various divisions of Class 2:

- Class 2.1: Flammable gases

- Class 2.2: Non-flammable, non-toxic gases

- Class 2.3: Toxic gases

However, it’s important to note that oxidizing gases are included in Class 2.2, with a subsidiary hazard of 5.1.

Therefore, they are regarded as:

- Class 2.2/5.1 non-flammable, oxidizing gases

IMPORTANT: A subsidiary hazard is an additional hazard, other than the primary hazard of that division of dangerous goods.

What are the Australian Regulations for Storing Oxidizing Gas?

In Australia, the storage and handling of oxidizing gases is regulated by the WHS laws of each state or territory. The specific regulations vary depending on the quantity and type of oxidizing gas being stored, as well as the intended use of the gas.

In general, the regulations require that oxidizing gases be stored in cylinders that are appropriate for the gas and that they are marked and labelled in accordance with relevant regulatory requirements.

The cylinders must be stored in a secure area that offers adequate ventilation for the safe dispersal of gases.

Class 2.2 subsidiary risk 5.1 gas stores must also be separated from the boundary of the work premises by a distance of at least 1 metre, with further consideration given to separation distances if the premises borders a protected place.

The segregation of gases, as well as other classes of dangerous goods, must be safe and compliant. Oxidising gas is incompatible with many other classes, so it’s crucial that you refer to the requirements specified in the product’s safety data sheet.

Personnel working with oxidizing gases must also receive the appropriate training and follow safety protocols to reduce risk in their work environment.

Any staff working with dangerous gases must have suitable training, supervision and PPE.

Some of the specific regulations for storing oxidizing gases in Australia include the Australian Dangerous Goods (ADG) Code and the Work Health and Safety (WHS) Regulations.

For more detailed requirements relating to Class 2 Gases, refer to the Australian Standard AS 4332 - The storage and handling of gases in cylinders. We’ll go into some of these storage and handling requirements a little further into our post.

What Harm Can Occur?

Working with oxidizing gases can be hazardous for people, property and even the surrounding community.

These compressed gases in cylinders pose significant health and safety risks if proper handling and storage precautions are not taken.

There are multiple hazards associated with these gases, including:

Fire and Explosion Hazards

Oxidizing gases can react with other materials to cause fires or explosions, and in some cases, these reactions can be violent and cause significant damage to equipment and property.

Corrosion

Oxidizing gases can be corrosive to some metals and materials, leading to damage and failure of equipment and infrastructure.

Toxicity

Some oxidizing gases can be toxic and harmful if inhaled or ingested. For example, chlorine gas can cause severe respiratory irritation, and fluorine gas is highly toxic and can cause severe burns and respiratory distress.

Oxygen Enrichment

Oxygen is an oxidizing gas and can pose a risk of oxygen enrichment, where the concentration of oxygen in the air exceeds safe levels. This can lead to an increased risk of fire and explosion, as well as causing respiratory distress or asphyxiation in workers.

Physical Hazards of Cylinders

In addition to these chemical or physiochemical hazards, there is also the danger posed by the pressurised gas within the metal cylinder. This physical hazard can create human harm and property damage, as well as allowing the cylinder to be damaged or comprised - which can increase the risk of other chemical-related hazards.

Any type of Class 2 gas has specific hazards that must be controlled to maintain a safe workplace.

REMEMBER: When in doubt, speak with a Dangerous Goods Consultant about the hazardous chemicals and dangerous goods at your worksite, so you can implement the correct controls necessary to greatly reduce risk. Every Australian workplace has an obligation to create a safe working environment, that adheres to the laws and regulations of their state or territory.

Physical hazards associated with oxidizing gas cylinders include:

Pressure Hazards

Oxidizing gases are often stored under high pressure, which can pose hazards during storage and transportation. A leak or rupture in a pressurized gas cylinder can cause severe injury or death due to the cylinder becoming a projectile capable of damaging people and property.

Physical Injuries Through Incorrect Cylinder Handling

When working with any type of gas cylinder, it's essential that the correct handling procedures are put in place. Gas cylinders are often large, heavy metal items, that are elongated in shape - making them difficult to manouvre.

Using gas cylinder handling equipment is an important control measure for compressed gases in the workplace.

Staff can become injured if the gas cylinders aren't moved with the use of gas bottle trolleys or lifting devices. Handling regulations also require the use of the appropriate personal protective equipment to keep staff safeguarded against oxidizing gas exposure through contact with the skin or eyes, or inhalation of an escaped gas.

REMEMBER: To minimize the risk of harm when working with oxidizing gases, it is crucial to follow all appropriate safety protocols, including proper storage, handling, and disposal of the gases and wearing appropriate personal protective equipment. It's also crucial that staff and contractors are properly trained to identify and control the risks associated with these dangerous goods.

Risk of Empty Gas Cylinders

When it comes to dealing with dangerous goods in the workplace, one of the most overlooked safety considerations is how to store and dispose of empty chemical containers.

As chemical residue, gas or vapours can remain in empty vessels, there must be procedures in place to ensure that these cylinders are stored and disposed of in a compliant manner.

As a rule of thumb, treat empty cylinders with the same precaution and care as you would a full gas cylinder. We suggest tagging cylinders that are full, in-use or empty. Assign specific storage for each type of cylinder.

Gas cylinders that aren’t in use should have their regulators removed, with the safety caps put back in place to minimise the likelihood and impact of hazards.

Why a Risk Assessment is Essential

Oxidizing gases, like any other hazardous substance, need a risk assessment to identify and evaluate potential hazards and risks associated with their use, handling, and storage in the workplace. The purpose of a risk assessment is to identify and assess the risks, to determine what measures need to be taken to control the risks, and to ensure that the workplace is safe for workers and other people who may be affected by the activities.

These chemicals can be extremely hazardous and have the potential to cause fires, explosions, or chemical reactions when they encounter other substances. Therefore, a risk assessment is necessary to identify the potential hazards associated with their use, including the likelihood and severity of incidents, as well as the measures required to prevent or control these incidents.

The risk assessment for oxidizing gases should consider several factors, such as the properties of the gas, the quantity used and stored, the handling and transfer procedures, the storage conditions, the surrounding environment, and the potential consequences of incidents, such as damage to equipment, injury to people, and impact on the environment.

By conducting a risk assessment, employers can identify the necessary control measures to reduce the risks associated with oxidizing gases and ensure the safety and health of workers and others who may be exposed to the hazards.

This may include implementing engineering controls, administrative controls, and personal protective equipment, as well as providing appropriate training and supervision to workers. These steps are laid out in a systematic manner in the Hierarchy of Controls.

Your risk assessment will identify hazards in your workplace, so you can start to control the risks using the Hierarchy of Controls.

Controlling Gas Hazards with the Hierarchy of Controls

The hierarchy of controls is a systematic approach to minimize or eliminate workplace hazards. There are five steps in the hierarchy of controls, listed in order of preference.

These steps are:

- Elimination: Remove the hazard altogether.

- Substitution: Replace the hazard with something less dangerous.

- Engineering controls: Isolate the hazard or modify the work environment to reduce exposure.

- Administrative controls: Change the way people work to reduce exposure.

- Personal protective equipment (PPE): Protect workers with the appropriate gear.

Measures to Control Oxidizing Gases

When dealing with these chemicals, the hierarchy of controls can be applied in the following ways:

Elimination: Where possible, eliminate the use of oxidizing gases by changing products and/or tasks. Elimination involves the complete exclusion of oxidizing gases in the work environment.

Substitution: If elimination is not feasible, consider substituting the oxidizing gas with a less hazardous alternative. For example, if a lower concentration of the oxidizing gas can be used, it should be considered.

Engineering controls: Implement engineering controls such as ventilation systems to control the concentration of oxidizing gases in the workplace. Additionally, equipment and facilities should be designed and installed to minimize the risks associated with the use of oxidizing gases.

Need advice on hazardous chemical storage?

Schedule a FREE consultation online

Administrative controls: Implement policies, procedures, and training programs to minimize exposure to oxidizing gases. For example, workers can be trained on the proper handling and storage of oxidizing gases, and warning signs and labels can be posted to alert workers to the presence of oxidizing gases.

Personal protective equipment (PPE): As a last resort, provide workers with appropriate PPE, such as respirators or protective clothing, to minimize the risk of exposure to oxidizing gases. See the Australian Standard

By following the hierarchy of controls, employers can minimize the risks associated with the use of oxidizing gases, ensuring the safety and health of their workers.

What Engineering Controls are Necessary for Oxidizing Gas Storage?

Engineering controls are an essential part of managing the risks associated with oxidizing gases in the workplace. Some of the engineering controls that may be required for oxidizing gases include:

Ventilation

Adequate ventilation is critical for controlling the concentration of oxidizing gases in the workplace. Ventilation systems should be designed to remove gases from the area and maintain a safe level of exposure for workers. Compliant gas cages feature ample natural ventilation, which allows for any escaped gas to flow into the outdoor environment, instead of accumulating within the storage system.

Separation and Segregation

Oxidizing gases should be separated and segregated from other incompatible chemicals, gases, and materials to prevent dangerous reactions from occurring.

Safe Storage

Gas storage cages can be used to store oxidizing gases safely and protect them from sources of heat, ignition, and combustible materials.

These cabinets are designed to protect the cylinders from impact damage and unauthorized entry. Restraint chains within the gas cylinder cage prevent the gas bottle from falling over, while the sturdy construction stops cylinders from becoming dangerous projectiles.

REMEMBER: Due to the risk of leaking cylinders, we always recommend that gas cylinders are stored in the outdoor environment. We suggest padlocking your gas cage to prevent unauthorised access and implementing additional security measures for your outdoor dangerous goods storage areas.

Pressure Relief Systems

Pressure relief systems can be used to prevent the buildup of pressure in oxidizing gas cylinders, which can reduce the risk of leaks or ruptures.

Fire Suppression Systems

Fire suppression systems, such as sprinklers or foam suppression, can be installed to control fires that may occur due to oxidizing gas leaks or releases.

Gas Detection Systems

Gas detection systems can be used to monitor the concentration of oxidizing gases in the workplace and provide an early warning of any leaks or releases. These systems can alert workers and trigger alarms to evacuate the area if necessary.

IMPORTANT: These engineering controls must be designed, installed, and maintained according to applicable standards and regulations to ensure their effectiveness in controlling the risks associated with oxidizing gases.

What PPE is Required?

When working with oxidizing gases, you must wear the appropriate personal protective equipment (PPE) to minimize the risk of exposure and potential harm. The type of PPE required will depend on the specific oxidizing gas being used and the potential hazards associated with it.

However, some of the common PPE used when working with oxidizing gases include:

Protective Clothing: Workers may need to wear chemical-resistant suits or aprons to protect their skin and clothing from contact with oxidizing gases.

Foot Protection: Chemical-resistant boots or shoe covers can be used to protect workers' feet from contact with oxidizing gases or chemicals.

Eye and Face Protection: Safety goggles or face shields can be used to protect workers' eyes and face from splashes or sprays of oxidizing gases.

Protective Gloves: Chemical-resistant gloves can be used to protect workers' hands from contact with oxidizing gases or chemicals.

Respirators: Air-purifying gas masks or supplied-air respirators can be used to protect workers from inhaling oxidizing gases. The type of gas mask required for your chemicals will depend on the concentration and toxicity of the gas.

IMPORTANT: Make sure you consult the chemical’s safety data sheet to ensure that you have the correct PPE for your workers. We also recommend keeping PPE in a dedicated cabinet and ensuring it’s regularly inspected and adequately maintained. Staff should also receive training on how to put on and take off the equipment, so the risk of chemical exposure is minimised.

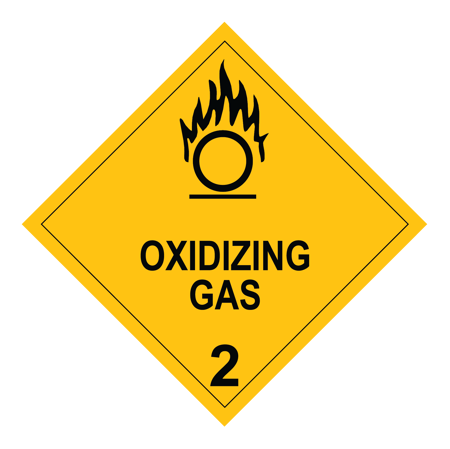

Signage for Oxidizing Gas Stores

Whether you're using a gas cage to store your cylinders, or you have constructed a custom gas store at your site, there are specific signage and placarding requirements for workplaces that store these chemicals.

Signage requirements may include:

- Oxidizing Gas 2 Dangerous Goods Diamond

- Flammable Gas 2 Dangerous Goods Diamond

- No Smoking, No Ignition Sources Within 3 M

In addition to installing the correct signage at your workplace, you must also ensure that it remains in good working order. We recommend regularly inspecting all your chemical controls, including dangerous goods and hazard signage, to ensure that any issues are corrected in a timely manner.

Mandatory Requirements for Gas Storage

If you'd like to learn more about the mandatory requirements that relate to oxidizing gas storage, why not download our free eBook, Gas Cylinder Storage: Compliance and Safety Requirements? Our guide details important information about these dangerous goods, including how to segregate them from hazardous chemicals, how to control the risk of gas leaks and impact damage, where to locate your store, and how to protect your staff from gas cylinder handling hazards.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.