Storemasta has invested heavily in state-of-the-art machinery to bolster manufacturing capabilities at their Tasmanian facility. This new capital investment will allow the company to significantly increase production capabilities, as well as streamline the prototyping process.

Improve and Accelerate Manufacturing

"In today's market and industry, we need to maintain our relevance and competitiveness. We need to be the best at what we do. There is no margin for second-rate production operations and second-rate operational capabilities, such as throughput, quality and reliability," explains Caleb Urquhart, CEO.

The machines will improve and accelerate the manufacturing capabilities of Storemasta, who are recognised as leaders in the dangerous goods storage industry.

“At the core of this investment is our strategic plan to double our throughput by 2025. This machine is a key enabler to do that.”

Caleb Urquhart, CEO Storemasta

Storemasta's Burnie Manufacturing Facility

Storemasta’s manufacturing facility, located in Burnie on the north west coast of Tasmania, produces their entire range of dangerous goods storage equipment, including battery charging cabinets, safety cabinets and dangerous goods containers.

“The new machines will reduce inventory, reduce waste and improve our working capital cycle. This will increase our throughput and efficiency,” says Caleb.

“We will also improve our ability to rapid prototype and deploy new ideas and solutions to the market faster than anyone else in the industry.”

Multiple AMADA manufacturing solutions have now been installed and programmed, with staff undergoing regular training and assessments to ensure the equipment is being utilised to optimum performance.

The AMADA machines eliminate rework time, ensure precision cutting and the creation of consistently perfectly proportional parts for the equipment.

Storemasta's investment in manufacturing technology is set to grow throughput, efficiency and prototyping.

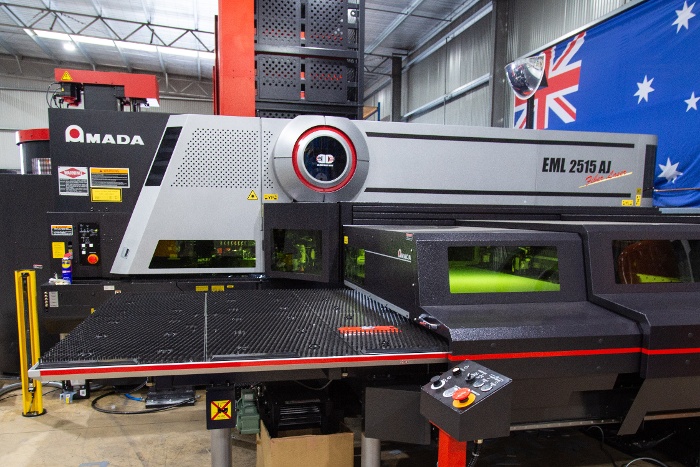

Some of the AMADA machines now housed in the Tasmanian facility include the AMADA fiber laser & turret punch, an automated tool change station and air blower punch.

The new AMADA fiber laser & turrret punch in the Burnie manufacturing facility.

Project Management

From the creation of the floorplan to the removal of old machines and the installation and commissioning of the new equipment, the project involved key personnel from Programming, Engineering, Production, Supply Chain and Management – with the project being delivered within the 6 week timeframe.

The bolstering of manufacturing technology displays the Australian owned and operated company’s ongoing commitment to increasing and improving manufacturing capabilities.

Grant McGuinness, Programming Specialist at Storemasta (pictured centre) with the AMADA team at the installation of the new machines.

Commitment to Build Manufacturing Capability

“Every department of business is making a step change to get us where we need to be by 2025,” Caleb explains.

“We have invested heavily in our machines, and it shows our commitment to continuing to manufacture and build up our manufacturing capability."

Storemasta is recognised as the leading dangerous goods storage and handling equipment manufacturer in Australia. With an experienced team of inhouse engineers and production professionals, Storemasta has been delivering dangerous goods storage solutions from concept to creation since 1992.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.