While most farms, gardens and agricultural enterprises rely on pesticides, it’s fair to say that they’re a product that requires careful consideration. If pesticides leak or spill they can cause a wide range of issues — from harm to humans, farm animals, wildlife and marine life to environmental pollution. And let’s not overlook the unnecessary costs associated with the loss of chemical stock. Considering all these risks, it’s important that your pesticides are controlled in a way that actively reduces the possibility of spillage. In this post, we’ll be looking at the simple ways that farmers and operators can manage their stores of pesticides to reduce the risks associated with these toxic or flammable products.

How Can Pesticides Spill?

Whether you’re busy running a farm, ag business, landscaping or gardening enterprise, there are many ways that pesticide chemicals can leak or spill.

Some spill incidents may be caused by a lack of adequate storage or handling equipment, old chemical containers or ill-fitting decanting equipment.

Pesticides can leak or spill in a variety of ways, including:

- Spray tank failure

- Old containers cracking with age or impact damage

- Drums or containers of pesticide not stored in a secure bunded area

- The transfer of chemicals across the farm in unbunded handling equipment

- Decanting pesticides into other containers

- Issues with the filling or use of spray bottles

What Are They Key Issues Associated With Pesticide Chemicals?

The majority of pesticides have either flammable or toxic properties (or both), due to the need for these chemical products to control and eradicate a range of common pests. Therefore, it’s important for operators to understand the need to meet compliance regulations, as well as adhere to the requirements of the Australian Standards.

Pesticides are an essential tool in pest control for households, businesses and ag enterprises.

While toxic and flammable substances are widely used throughout all types of industries, as well as in most households, the nature of agricultural enterprises means that pesticide usage is often in large quantities or in bulk. With any type of dangerous good, the larger the quantity that you’re using can increase the risks associated with the product. However, even small amounts of leaking fluid can cause major problems for agricultural businesses.

For example, toxic chemicals can quickly seep into soil, leech into dams or waterways, and produce significant amount of toxic vapours. The spill incident itself can cause damage to the staff members nearby, with toxic chemicals splashing into eyes or onto the skin — eye damage or even toxic poisoning. If your pesticides have Class 3 Flammable or Combustible properties, these seemingly harmless chemicals can ignite or even explode — in the presence of an ignition source.

Pesticides may be toxic or flammable, so check the SDS of your chemicals to determine the exact hazards.

Whether your business is carrying a few bottles of pesticide or multiple IBCs, it’s important to understand how to prevent and combat a pesticide spill. That way, you can work towards reduce chemical hazards that will affect the people, animals and crops of your enterprise.

How To Prevent Spillage

Using the Hierarchy of Control, and applying this to your pesticide stores, is an effective way to reduce spill risk. The Hierarchy of Control suggests key steps to minimising the likelihood and impact of a chemical hazard.

These steps include:

- ELIMINATE – take away the pesticide, if applicable to do so

- SUBSTITUTION – substituting harmful pesticides with lower risk products

- ISOLATION – ensuring that staff are isolated from the chemical through controls, keeping incompatible substance isolated to avoid chemical reactions

- ENGINEERING CONTROLS – implementing engineering controls such as bunded storage, bunded handling and transfer equipment

- ADMINISTRATIVE CONTROLS – using administrative actions to limit exposure to hazard

- PERSONAL PROTECTIVE EQUIPMENT – to protect your personnel from the harm caused by the pesticides

Like to know more about spill prevention?

How To Implement This In Your Business

The first step in reducing spill risk is to first attempt to eliminate or substitute the hazardous pesticides.Eliminate or Substitute Pesticides

While this method may not always be suitable for every business, you can still reduce the spill risk by keeping a tighter control on your chemical ordering processes.

If you can’t eliminate or substitute the pesticide chemicals, you can minimise the amount of stock you hold onsite by closely monitoring and managing your chemical ordering processes.

Isolate Workers and Incompatible Substances

Keeping your workers away from pesticides doesn’t mean relegating them to office duties. Isolation controls can include a vast range of solutions, including:

- Restricted access to handling and storage areas

- Adequate ventilation to avoid high concentrations of toxic or flammable vapours

- Having a specific room or compliant outdoor chemical container for decanting tasks. The area should be equipped with bunding and ventilation systems

Administrative Controls and PPE

The implementation of administrative controls and PPE are the two final steps in the Hierarchy of Controls. These come after the engineering controls have been put in place (we’ll get to that shortly).

Administrative controls suitable for farming and ag businesses may include:

- Written procedures for handling or storing pesticides

- Procedures for decanting of pesticides

- Extra training and supervision for high-risk tasks

- Chemical purchasing policies

- Restricted area policies

What Engineering Controls Can Be Applied To Ag Businesses?

While storing smaller amounts of pesticides in a shed or workshop may seem like a feasible option, it’s more likely that your hazardous chemicals require compliant bunded storage.

Under the WHS laws in your state or territory, you’re bound by obligations to ensure the safety of your operations, as well as the wellbeing of your staff. While pesticides are commonly found chemical products, they do require compliant storage to minimise spill risk.

IMPORTANT: If you’re unsure about the requirements that relate to your chemicals, refer to the Australian Standard AS 2507:1998 – The storage and handling of agricultural and veterinary chemicals. You’ll find detailed requirements that relate to the construction and location of chemical stores, as well as housekeeping procedures, the decontamination of containers, fire protection and waste disposal.

Pesticide Cabinets and Outdoor Storage Containers

To determine what storage is suitable for your pesticides, you should first start by checking the hazard class on the pesticide bottle or chemical container. This hazard information will assist you in determining the risks posed by that particular type of pesticide.

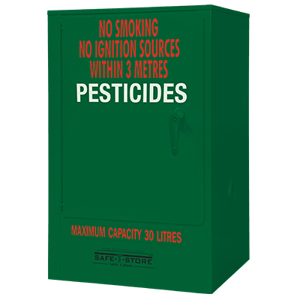

While you can store your farm chemicals in a cabinet or outdoor store (designed for that particular dangerous goods class), we recommend using a pesticide cabinet and pesticide relocatable.

These solutions are specifically designed and constructed for the storage of pesticides. When storing pesticides in an indoor environment such as a garden shed or workshop we suggest installing the pesticide cabinet.

For larger volumes of pesticides, consider choosing an outdoor storage container. Your store should be located in an outdoor position that complies to the separation distances detailed in the Australian Standard. This includes separation from public and private places, to reduce the risk of your stored chemicals creating a hazard for the local community.

What Features Reduce Spill Risk

As we touched on earlier in the article, spilled chemicals can cause a range of health and safety issues – especially in farming situations, where animals and crops rely on healthy soil and clean water.

Spillage can quickly spread into the natural environment, causing harm to farm animals, wildlife and the environment.

When selecting compliant pesticide storage, check that the dangerous goods storage equipment has:

For indoor storage – cabinet features:

SPILL CONTAINMENT: High-capacity spill sump 150mm deep

FIRE PROTECTION: Double walled sheet steel construction, 40mm thermic air barrier

PERFORATED SHELVING: To assist with the free flow of air within the cabinet, so vapours don’t build up in certain sections of the cabinet

DANGEROUS GOODS SIGNAGE: Including signs for Pesticides; Toxic or Flammable substances, and the DANGER: No Smoking, No Ignition Sources Within 3 Metres hazard sign.

Pesticides should be stored in a compliant cabinet in a safe, secure indoor location which is free from ignition sources.

For outdoor storage – chemical storage container features:

SPILL CONTAINMENT: High-capacity spill sump 150mm deep

VENTILATION: Natural ventilation system complying with AS/NZS 4452:1997

PERFORMATED SHELVING: To assist with natural ventilation and the dispersion of toxic or flammable vapours

OUTDOOR SECURITY: Container equipped with ISO locking bars to prohibit unauthorised entry which may result in spills and harmful vapour emissions

DANGEROUS GOODS SIGNAGE: Including signs for Pesticides; Toxic or Flammable substances, and the DANGER: No Smoking, No Ignition Sources Within 3 Metres hazard sign

REMEMBER: For the highest level of protection against chemical hazards, check that your storage equipment is manufactured to meet the requirements of AS NZS 4452:1997 - The storage and handling of toxic substances and AS 2057:1998 - The storage and handling of agricultural and veterinary chemicals.

Bunded Transfer and Handling Equipment

When moving chemicals around onsite, accidents can happen. Bunded equipment to assist with the smooth transfer of chemical containers can help decrease workplace injuries and accidental chemical spills.

Bunded equipment may include:

DRUM DOLLIES: For the easy transport of pesticide drums

BUNDED TROLLIES: When pesticides need to be moved in an indoor location

DISPENSING TRAYS: To allow for safer dispensing from chemical IBCs

DRUM CRADLES: To assist with decanting of pesticides in drums

Like To Learn More?

Keeping your agricultural operations running smoothly is made easier when correctly controlling chemical risk. To find out more about the prevention of chemical spills, you can access our free guide.

How To Protect Your Business From Chemical Spills details a range of solutions that can help contain hazardous chemical spills, so you can reduce the likelihood of toxic contamination, ignition of flammable vapours and harm to humans, animals and wildlife. Grab your copy now by clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.