While almost every Australian workplace carries some type of gas bottle, that doesn’t mean that the process of selecting gas storage is a straightforward one. Due to the hazards present within the chemicals, as well as the actual cylinder itself, getting your gas storage right is crucial for site safety. Afterall, fire hazards, impact damage and health effects such as toxic gases or asphyxiation, can occur if gas cylinder aren’t given the consideration they deserve. In this post, we’ll be comparing the different types of gas cages that you may require for your workplace. We’ll break down the essential factors to consider such as cylinder type, storage capacity and the functionality of the cage for your workplace tasks.

Features of Gas Cylinder Storage Cages

While all gases in cylinders pose a range of health, physiochemical and physical hazards, there are some basic construction features that are built into all gas cylinder cages.

Storemasta's Gas Bottle Storage Premium range is configurable to suit the cylinder or bottle size that you're storing.

These mandatory features include:

- Adequate natural ventilation – to ensure that gases are dispersed, instead of accumulating in low lying areas or within enclosed cabinets.

- Cylinder chains and restraints – as dropped or damaged gas cylinders can present a projectile hazard, it’s imperative that gas cages are constructed with chains and restraints to prevent cylinders from becoming unstable or turning into dangerous projectiles.

- Security – unauthorised personnel must not be permitted to handle gas cylinders. Therefore a mandatory requirement for gas cylinder storage is security measures to prevent theft, vandalism and unauthorised access.

- Compliant signage – as with all types of dangerous goods, compressed gases in cylinders must also be stored with the correct dangerous goods diamond/s and hazard signage to warn staff and site visitors of the hazards that are present within the store.

IMPORTANT: Find out more about the different types of gases found in the workplace by reading our popular blog, Dangerous Goods: Class 2 Gases. This post outlines commonly found gases, as well as how the hazards can impact safety in your operations.

Considerations for Gas Storage

The selection of gas cages in your workplace will depend on a range of factors that are specific to your operations.

When buying gas cages, consider the following points:

Location

What location will I be storing the gas in? Is there ample space or is floor space restricted? Does the store require extra security? Is there a risk of impact damage? Would single or double door access be more suitable for the gas cage location?

REMEMBER: We recommend storing gas cylinders in a cage that is situated outdoors, protected from direct sunlight, and out of the way of vehicles and equipment that could impact the storage facility.

Type Of Cylinder

What size and shape are your cylinders? Is the gas cage specifically designed to hold the type of cylinders that you’re seeking to store?

IMPORTANT: Storemasta provides a search functionality on their gas cylinder storage shop pages that allows you to quickly select the type of gas cylinder that you need to provide a gas cage for. Cylinder types can include various sizes of LPG, Acetylene and industrial gases.

Functionality of Cage

Does your gas cage have to be regularly moved to other parts of your worksite? Do you require a store that can be fixed to the ground - or do you need a cage with forklift channels?

Storage for Empty Cylinders

Due to the risk that empty cylinders pose, all gas cylinders should be treated with care as residue and hazards still remain. However, these cylinders should be stored in a separate gas cage so staff can tend to their tasks without confusion. Do you require an extra store to house empty or partially empty gas cylinders?

Cylinder Storage Capacity

The type and size of your cylinders will affect storage capacity. Always check the internal storage capacity and dimensions to ensure you are purchasing a gas cage that is suitable for your cylinders. You can calculate the required capacity based on the package size.

REMEMBER: We always suggest an onsite risk assessment when you’re bringing new chemical products into your workplace. If your team don’t have the expertise to conduct a risk assessment, please contact a Dangerous Goods Consultant who can help you meet your compliance obligations.

Comparing the Features of Different Storemasta Gas Cages

To illustrate the differences between Storemasta’s range of gas cylinder storage cages, we’ve created a table that outlines which features are relevant to each type of gas cage.

| Cage Type | Adjustable Chain & Bar Restraints | Padlockable Doors | Natural Ventilation | Bolt Down Plates | Forklift Channels | Suitable For Cylinder Types |

| LPG Cylinder Store | 9kg LPG bottles only | |||||

| Forklift LPG Cylinder Store | Forklift LPG bottles only | |||||

| Industrial Gas Cage | 90kg, Size R and S LPG (some models also suit Size T), Size D-G Industrial gas | |||||

| Acetylene Gas Cage | Size D, E and G Acetylene | |||||

| Medical Gas Cage* | Size C, CD and ND Oxygen cylinders |

Signage for Multiple Hazard Classes

Did you know that any dangerous goods, including compressed gases in cylinders, can have more than one dangerous goods class associated with the product?

When storing gases in the workplace, it’s extremely important to fully understand the hazards that you’re working with. If you aren’t sure what dangerous goods classes are assigned to your product, simply refer to the safety data sheet in Sections 2: Hazard(s) Identification and Section 14: Transport Information to determine the hazards and relevant hazard classes.

To illustrate the hazard classes for various gases in cylinders, we’ll be highlighting one product with a single dangerous goods class and another gas bottle that has multiple classes.

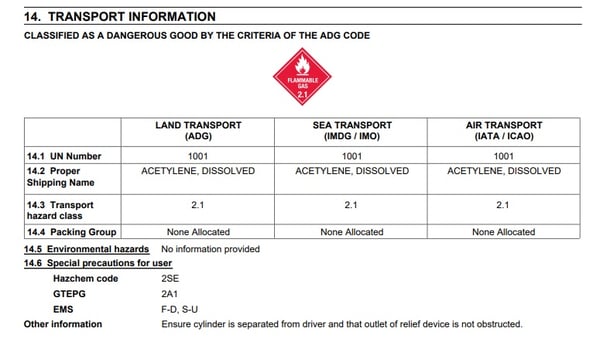

This acetylene gas cylinder is classed as a 2.1 Flammable Gas, as you can see from Section 14 of the safety data sheet.

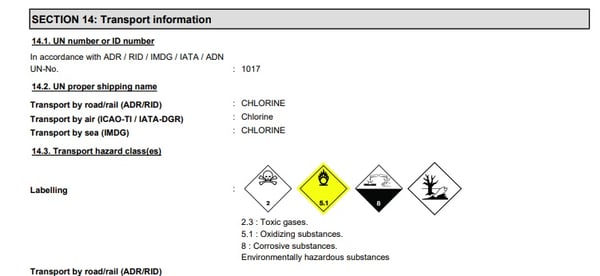

Whereas, this bottle of chlorine gas requires multiple dangerous goods diamonds including 2.3 Toxic Gases, 5.1 Oxidizing Substances and 8 Corrosive Substances. This is in addition to the environmentally hazardous substances hazard sign that must be displayed when storing this type of gas cylinder in the workplace.

Other hazard signage that you may require when storing gas cylinders at your jobsite includes No Smoking, No Ignition Sources signage, Caution: Keep All Cylinders Chained, Danger: Gas Cylinder Storage Area or Danger: Compressed Gases.

Storing Gas Cylinder Safety Data Sheets

If you’re keeping gas cylinders at your site, you need to be able to quickly reference the handling and storage requirements as per the product’s safety data sheet. Failure to provide safety data sheets for your staff can not only lead to non-compliance, but it can affect the safety of your workplace, as well as potentially, the surrounding environment and community.

Your safety data sheets should be less than 5 years old, and stored in a static position that is sheltered from moisture. We recommend purchasing a dedicated safety data sheet folder, as well as a clearly marked document holder — and attaching this SDS document holder to your gas cage or a nearby wall.

This will allow your staff to reference the safety data sheets when required, as well as providing access for any emergency services staff who may have to enter your premises in the event of an incident.

Gas Bottle Trolleys and Handling Equipment

While you may have got your gas cylinder storage sorted, don’t forget about the hazards that can occur when staff are using or moving your gas bottles around the workplace.

Dropping a gas cylinder can cause a range of serious safety issues, from physical harm to the staff member moving the cylinder to a physiochemical reaction, such as a damaged cylinder causing an explosion.

The safe handling of gas cylinders is essential for the health and safety of your workplace, so it’s a good idea to think about the ways in which you can reduce the likelihood and impact of a gas cylinder hazard.

Consider the following for your team:

- Ensure all staff are inducted onto site so they are aware of the hazards

- Create a gas cylinder (and dangerous goods) training program

- Invest in supervision and retraining to maintain a safe work environment

- Refer to your safety data sheets to make sure your personal protective equipment is suitable for the gases as well as the tasks that need to be performed

- Make sure that staff have PPE that is in good condition and a proper fit

- Utilise gas cylinder handling equipment, such as gas bottle trolleys or Rota trolleys, to minimise the likelihood of a dropped or damaged cylinder

- If you’re using machinery or equipment to move gas cylinders throughout the worksite, make sure that the equipment is properly maintained to ensure smooth operation

- Develop an inspection routine which monitors (and maintains) gas bottle trolleys, gas cylinder cages, PPE and other vital controls

Buying Gas Cages for your Operations

As we’ve highlighted in this post, gas bottle cages are an essential part of your overall chemical safety strategy. These durable cages will help reduce the risk of harm to people, property and the environment. In Australia, there are regulations and requirements that relate to compressed gases in cylinders. And while these requirements may be complex, we have an eBook that can help you understand your obligations. Why not access your free copy of Gas Cylinder Storage Compliance Safety Requirements now to learn more. Alternatively, get in touch with one of Storemasta’s Dangerous Goods Storage Consultants who can assist with all your gas cylinder storage needs. Fill out the form below and we’ll be in touch.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.