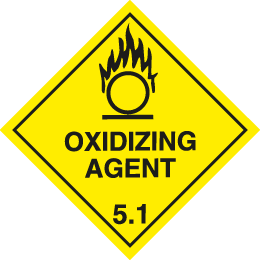

An oxidizing agent is a substance capable of causing oxidation. Widely used in industrial processes, they are essential for the production of items such as fuels and chemicals. These oxidisers are recognised as Class 5.1 dangerous goods and require compliant storage to reduce the many risks that they pose.

Examples of Oxidizing Agents

Oxidizing agents are diverse substances, ranging from simple molecules to complex compounds.

Here are some common examples of oxidizing agents that you may already be working with:

- Oxygen gas: Oxygen gas is one of the most familiar oxidizing agents. It supports combustion and is essential for many oxidation reactions.

- Chlorine: Chlorine gas is a strong oxidizing agent commonly used for water disinfection and in the production of various chemicals. It can oxidize organic materials and is highly reactive.

- Hydrogen peroxide: Hydrogen peroxide is a widely used oxidizing agent in various applications, including bleaching, disinfection, and rocket propulsion. It can oxidize a wide range of substances, often releasing oxygen gas in the process.

- Potassium permanganate: Potassium permanganate is a potent oxidizing agent used in water treatment, laboratory experiments, and as a reagent in organic synthesis. It can oxidize organic compounds and reduce to manganese dioxide.

- Permanganates: Besides potassium permanganate, other permanganates like sodium permanganate and barium permanganate also serve as potent oxidizing agents, used in various industrial and laboratory applications.

However, there are many more substances with oxidizing properties.

It's important to handle them with care and follow appropriate safety measures due to their potential hazards. We’ll look at this topic in the next section of our post.

Hazards of Oxidizing Agents

Oxidizing agents are substances that can cause other substances to undergo oxidation, meaning they lose electrons.

While these dangerous goods are essential in various chemical processes, they can also pose serious risk to people, property and environment if not handled and stored in the right way.

Here are some common physiochemical hazards associated with oxidizing agents:

- Fire and Explosion: Many oxidizing agents are highly reactive and can react violently with combustible materials. They can initiate or intensify fires and explosions in the presence of flammable substances — even without an external ignition source.

- Reactivity with Organic Materials: Oxidizing agents can react vigorously with organic compounds, leading to chemical reactions that produce heat, gases and hazardous byproducts. This reactivity can result in fires, explosions or toxic fumes.

- Incompatibility: Oxidizing agents may react dangerously with other dangerous goods or substances — particularly reducing agents, which donate electrons. Mixing incompatible substances can lead to rapid and uncontrollable chemical reactions, posing significant risk.

Division 5.1 Oxidising Agents have physiochemical and health hazards and must be placarded appropriately to alert staff members to these hazards.

Health Hazards of Oxidizing Agents

Some oxidizing agents may also pose other health risks, depending on their chemical properties.

Some may be toxic to humans and animals. Exposure to oxidizing agents may cause irritation, burns or severe health effects, depending on the specific chemical and concentration.

Oxidizing agents can also corrode or degrade living tissues, as well as various materials such as metals and stone. This corrosion can weaken structures, damage equipment and harm humans and the environment.

What is the Australian Standard for Oxidizing Agents?

To determine the best practice storage and handling for oxidizing agents, turn to the relevant Australian Standard.

AS 4326 - The storage and handling of oxidizing agents details all requirements for workplaces managing the risks of oxidizing agents.

When storing your chemicals, make sure the equipment is built for purpose, so the design and construction is specific to the risks posed by the oxidising agents.

Oxidixing agents may be stored indoors or outdoors, depending on your risk assessment and the quantities you hold.

Safe Storage of Oxidizing Agents

Handling oxidizing agents requires careful attention to safety protocols to minimize the risk of accidents and exposure.

Here are some general guidelines for handling oxidizing agents safely:

- Personal protective equipment (PPE): Wear appropriate personal protective equipment, including gloves, safety goggles, lab coats, and respiratory protection, if necessary, to protect against exposure.

- Handling chemicals: Use proper handling techniques, such as using dedicated equipment (e.g., pipettes, spatulas) for transferring oxidizing agents and avoiding contact with skin or clothing. Handle them in a fume hood or well-ventilated area to minimise inhalation exposure.

- Oxidizing agent spills and leaks: Clean up spills immediately using appropriate absorbent materials and follow established spill response procedures. Avoid creating aerosols or allowing the spilled material to encounter incompatible substances.

REMEMBER: Conduct a thorough risk assessment before working with oxidizing agents to identify potential hazards and implement appropriate control measures to mitigate risks in your workplace.

How to Store Oxidizing Agents with Safety and Compliance

While there are many considerations when storing oxidizing agents in the workplace, there are some key takeaways to factor into your storage procedures:

- Store oxidizing agents in well-ventilated areas; indoor storage cabinets require mechanical ventilation.

- Keep substances away from heat, direct sunlight and sources of ignition. The Australian Standard states that sources of heat and fire be separated by at least 3 metres from the opening of a Class 5.1 store.

- Ensure correct placarding of stores so staff know what dangerous goods are stored and that authorised personnel are only allowed to enter the area.

- Segregate oxidizing agents from other chemicals (and incompatible oxidizing agents).

IMPORTANT: If oxidizing agents have subsidiary risk or risks, the greatest separation and segregation distances will apply.

Types of Oxidizing Agent Package Stores

The types of oxidizing agent packages stores that are deemed as suitable by the Australian Standards include, but are not limited to:

- Storage cabinet

- Freestanding roofed structure or building

- Room or area attached to external wall of another building

Due to the cost-effectiveness and simplicity of installing a compliant storage cabinet, the Class 5.1 Oxidizing Agent Storage Cabinets are often a popular solution for indoor storage.

Alternatively, a purpose-built Class 5.1 Outdoor Storage Container can offer adequate protection for the goods if stored in the outdoor environment.

IMPORTANT: Safe storage is only the first step. It’s important to follow proper safety protocols, including conducting risk assessments, providing adequate training to personnel, using appropriate protective measures, and implementing strict storage and handling procedures.

Construction Features of a Class 5.1 Cabinet

One of the key construction features of an Oxidising Agent Storage Cabinet is the door closing system. Storemasta Class 5.1 cabinets provide self-closing, tight-fitting doors which automatically release if there is a build-up of pressure (chemical reaction) within the storage unit.

Spill containment, double walled sheet steel construction with thermic air barrier, and perforated shelving (to prevent build-up of oxidizing agents in corners or ledges of cabinet) add to the overall control of oxidizing agent storage risks.

Features of an oxidising agent indoor storage cabinet include doors that can release automatically if there is a build up of pressure within the storage equipment.

Mechanical ventilation is required for your Class 5.1 cabinet or bulk store. The ventilation system must be compliant, and exhaust directed away from ignition sources – as well as areas in which people may congregate. The ventilation system must be sufficient to ensure exposure levels are within the limits set by the workplace exposure standards.

REMEMBER: Storemasta Oxidizing Agent Storage Cabinets are equipped with built in flash arrestors and vent openings for mechanical ventilation systems.

Emergency Decontamination Equipment for Class 5.1 Dangerous Goods

To reduce the impact of an accident or spill in the workplace, Emergency Decontamination Equipment is required for stores that hold oxidizing agents.

The appropriate gloves (see the safety data sheet of your substance) and water for hand washing must be provided.

However, we recommend conducting an onsite risk assessment to determine your need for equipment such as safety showers and emergency eyewash stations.

Managing the Risks of your Dangerous Goods

If you’d like to learn more about risk management of substances such as oxidizing agents, grab a copy of our free eBook. This detailed guide offers practical guidance to assist with you identifying hazards, assessing risks and controlling oxidizing agents in your workplace. Download your copy today to learn more about Hazchem and dangerous goods safety for your own operations.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.