If your organisation uses substances that are classified as oxidising agents, it's very important that you store and handle them in a way that minimises the risks they pose upon people, property and the environment. The Australian Dangerous Goods Code defines division 5.1 oxidising agents as:

Substances which, while in themselves not necessarily combustible, may, generally by yielding oxygen, cause, or contribute to, the combustion of other material. Such substances may be contained in an article.

Defining Oxidising Agents

As stated in the Australian Dangerous Goods Code, the dangerous property associated with oxidising agents is their ability to contribute to the combustion of other material by yielding oxygen. Oxidising agents can:

- Increase the rate at which a fire develops making it more intense

- Cause substances that don’t normally combust readily in air to burn rapidly

- Cause combustible substances to burn spontaneously without the presence of an ignition source.

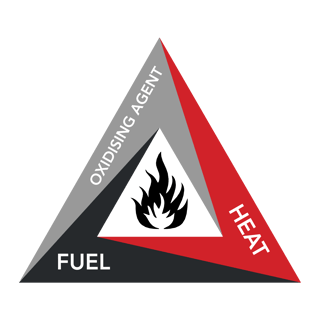

For combustion to successfully take place three critical elements are required. These elements include; fuel, heat and an oxidising agent. This concept is often referred to as the triangle of combustion.

Triangle of Combustion

To reduce the risk of combustion, you have to remove one of the three essential elements of combustion. Therefore if you store oxidising agents in your workplace, the risk of combustion can be minimised by decreasing the concentration of the oxygen vapours that come from the oxidising agent. The concentration of the oxidising vapours can be reduced by installing a ventilation system on you oxidising agent storage cabinets.

Ventilation requirements according to AS 4326-2008

The Australian Standard that outlines the ventilation requirements for oxidising agent storage cabinets is AS 4326-2008 - The storage and handling of oxidising agents. Section 4.8.3 of this standard states:

“Where appropriate, cabinets shall be vented to atmosphere, away from ignition sources and areas where persons are likely to congregate.”

As this standard states that “cabinets shall be vented” it means that ventilation of oxidising agent storage cabinets is a mandatory requirement. A ventilation system will reduce the concentration of oxidising gases and vapours to a safe limit reducing the risk of unexpected combustion. The workplace exposure standards also apply.

Workplace exposure standards

Exposure to any kind of hazardous substances will pose significant health risks upon your workers. Some of these health risks include:

- Asphyxiation

- Vomiting

- Nausea

- Headaches

- Irritation to the eyes, ears and throat

- Dizziness

To help combat these health risks, Safework Australia developed the workplace exposure standards. These exposure standards identify around 700 hazardous substances and their legal airborne concentration limits.

If the oxidising agent that you are storing is listed in the workplace exposure standards, it’s important to ensure that the ventilation system is capable of keeping the concentration of the oxidising vapours below the maximum legal limit specified in the workplace exposure standards.

Features of a compliant ventilation system for oxidising agents

When you install a ventilation system on an oxidising agent storage cabinet, it's important to ensure that it doesn’t pose any further risks to the people in your organisation. A safe and compliant ventilation system for an oxidising agent storage cabinet must be installed in line with the requirements outlined below:

- A mechanical ventilation system should be designed so that it prevents any vapours from escaping into the room.

- The ventilation system shall be vented to the outside atmosphere in a location that is safe to disperse oxidising vapours. A safe location will be away from ignition sources and places where people congregate.

- The air inlet shall be attached to the vent port at the top of the cabinet and the oxidising vapours shall be extracted from the bottom vent port via the exhaust fan. This configuration is most effective as most hazardous vapours are heavier than air and reside in the bottom of the cabinet.

- A ventilation system must not be linked to multiple cabinets. A ventilation system connected to multiple cabinets could cause vapours from incompatible dangerous goods to mix, resulting in violent chemical reactions.

- When a mechanical ventilation system is not attached to a oxidising agent storage cabinet, the vent bungs must be tightly screwed into the vent ports. This stops any oxidising vapours from escaping into the workplace.

- In all instances the ventilation system shall not compromise the structural integrity of the cabinet.

- In all cases the ventilation duct must not be smaller than the size of the vent opening on the side of the cabinet. A ventilation system must be designed by an appropriately qualified engineer and it must comply with AS/NZS - 1668.2-2002

Next Steps

As oxidising agents have the ability to contribute to combustion by yielding oxygen, its important to ventilate oxidising agent storage cabinets to bring the concentration of oxidising gases to a level that won’t cause unexpected combustion. A safe ventilation system for oxidising agent storage cabinets must comply with the requirements outlined in AS4326-2008. For more detailed information on how to ventilate other dangerous goods storage cabinets, including those used for the storage of flammable liquids and corrosive substances, download our free eBook by clicking on the image below 👇.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.