How should flammable liquids be stored? It’s a question that we get asked often by our customers — and the answer is crucial to maintaining chemical compliance and safety. While flammable liquids are one of the most commonly used classes of dangerous goods, they are also one of the most volatile. If your business is one of the many that carries Class 3 Flammable Liquids, you have a legal obligation to ensure that these chemicals don’t cause harm to the people, property and environment of your organisation. By understanding the requirements of safe chemical storage, you can effectively reduce your risk of fire, explosion and human harm.

Before we explain exactly how and what flammable liquids should be stored in, we’ll have to refer to the storage requirements that are set out in the Australian Standards.

Requirements For Safe Flammable Liquids Storage

The requirements for the safe storage of flammable liquids is outlined in the Australian Standard AS 1940:2017 - The storage and handling of flammable and combustible liquids.

Australian Standards are comprehensive documents that set out specifications, guidelines and procedures to ensure that products, services and systems are consistent, reliable and safe.

AS1940-2017 outlines a range of different facilities that can be used to store flammable and combustible liquids in a compliant manner.

Even though the design specifications of each of these storage facilities differ, they all provide adequate protection against the risk associated with flammable liquids.

When storing flammable liquids, the Standard explains that there are a variety of options. These flammable liquid storage facilities include:

- A detached store, being a store with or without a roof, or walls other than a bund

- An attached fire-separated store, being a store attached to a building with outside entry and no communication to the associated building

- An attached store, sharing a wall or walls with the associated building and with a communicating fire door between the store and the associated building

- An internal store, being a store wholly within a building, not sharing a common wall with the building and communicating with the associated building

- Fire-separated stores, being grouped stores with no communication between adjacent storages

- A storage cabinet located within a building or located outside a building as an outdoor storage

- Facilities for the holding of materials awaiting use in a process, machine or the like

- A detached store, being a freight container complying with the requirements of clause 4.8 of AS 1940:2017

Although the standard details a range of compliant flammable and combustible liquid storage facilities, there are two types that businesses usually opt for due to their safety and practicality.

These two types of flammable liquids store include:

- Indoor locations: Flammable storage cabinet

- Outdoor locations: Relocatable detached flammable liquid store

We’ll now have a look at the design requirements for these two types of Class 3 Flammable Liquid storage facilities.

Indoor Flammable Liquids Storage Cabinet

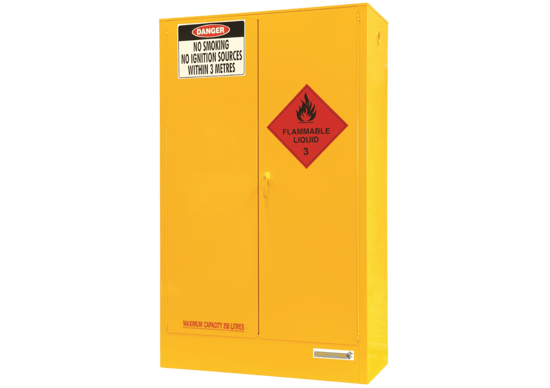

For indoor flammable liquids storage cabinets to reduce the risks posed by flammable liquids, the cabinet must feature a safe and sturdy construction.

One of the most effective options for the safe storage of flammable liquids is a compliant indoor flammable liquids storage cabinet.

One of the most effective options for the safe storage of flammable liquids is a compliant indoor flammable liquids storage cabinet. Section 4.9.2 of AS 1940:2017 sets out the flammable storage cabinet construction requirements.

These mandatory requirements include:

- Construction: The walls, floor, doors and roof of the flammable cabinet must be constructed from a double-walled sheet steel construction. The gap between these walls must be no less than 40mm and can be left empty or filled with a fire-resistant insulation.

- Sealed Gaps: The gaps around the doors and the walls of the flammable storage cabinet shall be sealed to prevent heat radiation and the spread of flames in the event of a fire.

- Liquid-Tight Sump: The base of the cabinet shall form a liquid-tight spill containment sump of at least 150mm deep. This sump must be designed in such a way that packages are prevented from being stored in the sump. This sump will contain any spills that may occur inside the cabinet.

- Shelving: The shelves inside the cabinet must be perforated to allow for free air movement inside the cabinet. The shelves should also be sturdy and capable of carrying the maximum possible load.

- Spills: The inside of the cabinet including the shelves shall be designed in such a way that any spills are directed into the sump in the base of the cabinet.

- Doors: The doors of the cabinet shall be self-closing, close-fitting and held shut automatically by catches at two or more points.

- Door Holding Device: If the doors are equipped with a device to hold the doors permanently open when the cabinet is being loaded, the doors must automatically close when the temperature exceeds 80°C.

- Materials: Materials that are critical to the structural integrity of the cabinet must not melt at temperatures below 850°C. Seals and gaskets are an exemption to this requirement.

Flammable Storage Cabinets Exceeding 250L Capacity

For flammable cabinets with a storage capacity that exceeds 250L, extra features must be added to the construction of the cabinet. When workplaces store flammable liquids in a larger capacity flammable liquids storage cabinet, the extra features provide sufficient protection against the risk of storing greater chemical quantities.

Additional requirements for flammable storage cabinets over 250L includes:

- The height of the cabinet shall not exceed 2 meters

- The external surfaces of the cabinet shall be constructed from sheet steel of at least 1 mm thick.

- The spill containment sump in the base of the cabinet shall be capable of containing at least 25% of the aggregate capacity of the cabinet or the capacity of the largest container being stored in the cabinet, whichever is greater.

For flammable cabinets over 250L in capacity, additional construction requirements do apply.

Outdoor Relocatable Detached Stores

Storing flammable liquids indoors poses great risks upon the people and property of your organisation. So, to mitigate this risk, Standards Australia limited the capacity of indoor storage cabinets to 850L. This limitation ensures that Australian businesses store larger quantities of flammable liquids outdoors.

Outdoor relocatable detached stores are flammable liquid storage facilities that are used to store flammable liquids outdoors. Outdoor relocatable detached stores, otherwise known as Class 3 Flammable Liquid storage containers, can range from 80L to 10,000L in capacity.

Just like the indoor flammable storage cabinet, these outdoor containers are subject to a range of requirements regarding their design and construction, spillage containment capacity and ventilation.

These approved containers feature the necessary controls to reduce the risks associated with the outdoor storage of flammable and combustible liquids.

The design requirement for outdoor relocatable detached stores according to AS 1940:2017 include:

Construction

Other than fire-rated structures, all outdoor flammable liquid storage facilities shall be constructed from masonry, concrete, or a structure sheeted with non-combustible material. Any skylights that might be necessary are not required to be constructed from non-combustible material.

Outdoor relocatable storage facilities are specifically designed and constructed to protect larger quantities of flammable liquids in an outdoor environment.

Floors on flammable liquid storage facilities that make up part of the spillage catchment system shall be impervious and not liable to degradation or incendive sparking.

Spillage Containment

It is a requirement of WHS Regulations and the Australian Standards that all outdoor flammable liquid storage facilities have the provision to contain chemical leaks and spills.

The spill containment system must be designed to prevent any flammable liquids from contaminating the soil in the surrounding area. The system shall also prevent flammable liquids from entering any drainage system or water course.

All spillage containment systems installed on outdoor flammable liquids storage facilities shall comply with the following requirements.

- The spill containment compound must be impervious to retain spillage. The compound must also enable the recovery of the contents that have been spilled.

- Any pipework that is used to direct any spill contents to a remove spill containment tank must be fire resistant. Flashback protection must be provided between the outdoor flammable liquids storage facility and the remote spill containment tank.

- The capacity of the spill containment sump must be at least 100% of the volume of the largest package inside the store, plus 25% of the storage capacity up to 10 000L, together with 10% of the storage capacity between 10 000L and 100 000L, and 5% above 100 000L

- If a manual or automatic water-based fire suppression system is installed in the storage facility, the spill containment sump must be increased to a volume equal to the output of the fire suppression system over a 20 minute period.

- Any drainage system shall be capable of containing the output of the sprinkler system for the number of sprinklers operating at the required pressure outlined in AS 2118.1

- Drainage of any rainwater or fire water to outside the compound must be via a suitable interceptor or separator, or after sampling and testing the water.

- When more than one flammable liquids storage facility is connected to a common spill containment sump, the capacity of the sump must be equal to the capacity required for the largest package store, plus 25% of the capacity of the spill containment requirements for the other connected storage facilities.

Ventilation

Each outdoor flammable liquid storage facility must be provided with adequate natural or mechanical ventilation to suit the type of Class 3 Flammable Liquids that are being stored.

The ventilation system shall be sufficient to ensure that all vapours and fumes generated within the store are diluted and removed by air passing through the store.

Due to the risk of ignition with flammable vapours, the ventilation of the cabinet or store is an important safety consideration. However, we suggest conducting a risk assessment at your site to see if your flammable cabinet requires mechanical ventilation.

If you’re storing your Class 3 flammable and combustible liquids in an outdoor relocatable store, you won’t have to supply mechanical ventilation. This is due to the requirements for natural ventilation systems as stated in the Australian Standard.

Outdoor flammable liquids stores are designed with natural ventilation systems, such as fixed louvres on two opposing sides of the flammable container. This allows the natural dispersion of flammable vapours — and decreases the risk of ignition.

IMPORTANT: All flammable storage cabinets and relocatable flammable outdoor stores must feature the appropriate dangerous goods signage and hazard signage. This includes signage to prohibit ignition sources within 3 metres of the flammable cabinet or outdoor flammable storage container. Ignition sources are things which produce enough energy to spark flammable vapours, and include hot surfaces, tools that produce sparks, electrical equipment and static electricity.

Ventilation Requirements for Dangerous Goods Storage Cabinets

The workplace exposure standards, as published by Work Safe Australia, also apply when the type of flammable liquids being stored are listed in that standard.

A compliant natural ventilation system for an outdoor flammable liquids storage facility shall be one of the following configurations outlined below:

- A store with at least two walls completely open to the outside atmosphere.

- A wall of fixed louvers, lattice or wire mesh having at least 50% of its area as openings.

- One wall of the store being completely open to the outside atmosphere with no other vents in the store. In this case the distance to, and the length of, the opposite wall must not exceed the length of the open wall.

- Vents in one external wall, provided that the wall is at least 6m long and the opposite wall is no more than 5m away from the vented wall.

- One wall open to atmosphere and vents in one opposite or adjacent wall

- Vents in two opposing walls

In all cases, vents should be located along the longest sides of the building and should be positioned to limit areas where there is no effective ventilation.

With large stores, consideration must also be given to providing additional vents on adjacent walls and/or providing vents larger than 0.1m2 or 0.15m2.

How Does Your Business Store Class 3 Flammable Liquids?

As we’ve highlighted in this blog, flammable liquids and combustible liquids are volatile substances, they have the potential to easily ignite and cause harm to your staff, your business, the environment and your community. You should store flammable liquids in compliant cabinet or outdoor chemical storage container to protect your organisation from the risks that these chemicals pose. If your business is carrying any quantity of Class 3 liquids, it’s vital that you follow the requirements for safe chemical storage as set out in AS 1940:2017.

Would you like to learn more about how to store flammable liquids? We have an eBook that can help. How To Reduce The Risk Of Flammable Liquids In The Workplace details our 4-STEP risk control methodology and offers practical and easy-to-follow tips for chemical compliance. Simply click on the image below to access your free copy today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.