When you’re working with gas cylinders, such as oxygen, butane or LPG cylinders, there is always the risk of a gas cylinder fire or explosion. n this post, we’ll be offering practical controls to protect your cylinder store from hazards posed by fire and radiant heat, including isolating the gas store from site buildings and combustibles, and restraining cylinders within a secure gas bottle cage.

What is the Australian Standard for Gas Cylinders?

To determine the best practice for gas cylinder storage and handling – to reduce risks such as rupturing, leaks, gas cylinder fires or explosions – you can refer the relevant Australian Standard.

AS4332 - The storage and handling of gases in cylinders is the Standard that applies to gases stored in cylinders under pressure, offering detailed guidance on how to reduce risk in your operations.

The Standard explains that gas cylinders are to be protected from fire and radiant heat. It also stipulates, amongst a range of other requirements, that you must ensure your worksite has adequate fire protection facilities.

IMPORTANT: When considering fire protection equipment, you should be incorporating the hazards and needs of the whole site — and not just the portion where gas bottles are stored.

Gas Cylinder Hazards During A Fire

Gas cylinders present a range of complex hazards that are exacerbated during a fire.

The Standard identifies the following specific hazards that are presented by gas cylinders during a fire:

- Heated cylinders can explode or rupture catastrophically

- Impacted or fallen cylinders can become dangerous missiles or projectiles

- Cylinders are vulnerable to damage by emergency responders as well as water pressure from hydrants and fire hoses

- Gas leaks or an uncontrolled release of Class 2.1 Flammable Gases will feed a fire

- Uncontrolled releases of Class 5.1 Oxidising gases will intensify the fire

- Gas leaks from Class 2.3 Toxic and Corrosive gases could fatally injure workers or emergency responders (though sometimes in the turbulence of a fire, the gases are completely dispersed).

- Some Class 2.1 Flammable Gases can release toxic fumes in a fire (fluorocarbon refrigerants will do this).

- Toxic smoke, chemical residues and other run off from fires can harm nearby communities or the natural environment

IMPORTANT: While they may be a common site at workplaces, gas cylinders pose both physical and chemical risk to people, property and the environment. This is due to the hazards associated with the stored substance, the pressure involved with gas cylinder storage, as well as the metal cylinder itself.

Can Gas Bottles Explode In The Heat?

Gas bottles can explode if they are subject to intense heat through a workplace fire or radiant heat. The heating of the gas cylinder increases pressure within the vessel and may also compromise the strength of the gas bottle. If gas cylinders are exposed to a fire, they can rupture and explode – posing danger to people and property.

Ruptured gas cylinders can create further hazards due to the nature of the chemicals that are stored under pressure, including flammable, toxic, corrosive or oxidising gases.

Need to know more about gas cylinder compliance?

What Temperatures are Dangerous for Gas Cylinder Storage and Handling?

The temperature at which cylinders can be compromised or rupture depends on the cylinder and its contents.

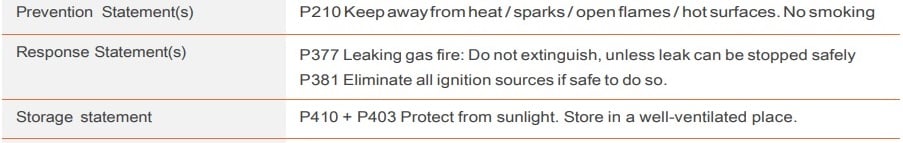

For example, we'll take a look at a safety data sheet for an LPG cylinder (see below).

This particular LPG cylinder, from Origin, must be kept at a temperature below 45 degrees Celsius, in a well-ventilated area that is protected from direct sunlight.

The safety data sheet also specifies “may explode if heated”.

Safety Data Sheet - LPG, Origin

Always refer to your cylinder's safety data sheet to ensure you're adequately protecting your cylinder from temperatures that may spark a hazard.

Fire Extinguisher and Protection Facilities

Any worksite that holds gas cylinders you must have adequate fire extinguishers and fire protection facilities in place. This will vary depending on the quantity of cylinders and the types of gases you are using, but in general the fire protection facilities should fulfil three clear functions.

The purpose of fire protection facilities are to:

(a) Control and extinguish fires

(b) Protect cylinders from heat

(c) Disperse smoke, vapours and leaked gases

NOTE: At smaller worksites, water from a fire hose may be capable of fulfilling all three functions (extinguish the fire, cool the cylinders and dissipate leaked gases). Always make sure you conduct a thorough risk assessment to examine the effectiveness of any proposed fire protection measures.

Provision for Gas Cylinder Fire Protection

The Standard has clear specifications for fire protection systems including the provision, inspection and maintenance of:

- Fire extinguishers

- Fire sprinkler systems

- Hose reels

- Hydrants

- Suitable water supply

- Fire alarm systems

- Monitoring systems

- Radiation barriers

- Weather protection

- Emergency procedures

However, another important consideration to minimise the fire hazards affecting your gas cylinders is to isolate your cylinder store — and keep your gas bottles restrained in a secure gas bottle cage.

IMPORTANT: Creating effective emergency procedures is essential for any workplace that keeps gas cylinders and other dangerous goods. From how to combat a fire incident to who will alert the fire brigade, there are a multitude of factors to consider when looking at emergency planning. Read our post to find out more.

Isolating Your Cylinder Store

Keeping your cylinders in a secure (and heavy duty) gas bottle cage protects your gas cylinders from impact as well as containing heated bottles that might explode or become dangerous missiles themselves. Because cylinders are vulnerable to being knocked over by water pressure from fire hoses (or fire responders accessing the worksite) it’s essential to keep cylinders individually restrained inside the store.

Wherever possible cylinder stores should be located outside. By storing cylinders in a secure, compliant store in an outdoor area, you’ll be able to reduce risks associated with leaking or escaped gases. An outdoor gas store can also help you to isolate the cylinders from operating plant, buildings and warehouses, or the production floor.

Not only are the cylinders protected from industrial heat, but they are also less likely to become involved in a fire that breaks out in those areas, or alternately, spread a fire in the store to the key operating areas of your worksite.

The Standard specifically requires that gas cylinder stores must be located:

- At least 3 metres from combustible or flammable materials, vegetation and refuse

- At least 1 metre from building windows, doors, air vents and ducting

Storage to Reduce Gas Cylinder Fire Risk

Australian Standard AS4332 has other requirements for preventing cylinder stores from becoming involved in a fire (or causing one).

Some of these include ensuring that gas cylinder stores are:

- Constructed from non-combustible materials

- Designated no smoking areas

- Accessed by authorised personnel trained in gas cylinder safety

- Isolated form ignition sources and heat

- Sufficiently ventilated using either natural air flow or a mechanical ventilation system

- Located away from other dangerous goods and hazardous chemicals

Store gas cylinders in a compliant gas cage in a suitable outdoor location. Ensure the correct dangerous goods and hazard signage is visible and maintained.

Segregation of Gases

Fire, explosions and other hazards can also be controlled through careful segregation. As we mentioned in the above section, you must locate your gas cylinders away from dangerous goods and hazardous chemicals that are incompatible or may cause a reaction.

Class 2.1 (flammable gases), Class 2.2 (5.1) (non-flammable, oxidising gases) and Class 2.3 (toxic gases) must be segregated within your cylinder store by at least 3 metres to maintain safety and compliance.

IMPORTANT: Like to learn more about isolating gas cylinders from hazards, such as incompatible dangerous goods or other classes of gases? Read our popular post to learn more about chemical segregation.

Fire Gas Cylinder

Are you a WHS Manager or site supervisor with OHS responsibilities for reducing the risks associated with gas cylinders? Why not download our free eBook Gas Cylinder Storage: Compliance and safety requirements to learn how to apply a risk management methodology at your worksite and store your cylinders safely. Get your copy now to find out more about protecting your premises from gas cylinder fires and explosions.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.