When it comes to workplace gases, acetylene is one of the most widely used fuel gases. However, there have been many instances of acetylene accidents that have destroyed property and harmed unsuspecting workers while they carried out their duties. In this post, we look at the properties of acetylene to explain if this gas poses a danger to your workplace.

Understanding Acetylene

As one of the world’s most used gases, this volatile substance produces the highest flame temperature of any fuel gas.

Accidentally discovered in 1836 by Edmund Davy, the gas was rediscovered by Marcellin Berthelot 24 years later when the French chemist determined that acetylene formed through sparking electricity through the mix of cyanogen and hydrogen.

The gas is a hydrocarbon (ie. an organic compound of hydrogen and carbon) and the simplest alkyne (ie. an unsaturated hydrocarbon). The chemical structure of acetylene is H−C≡C−H, with the formula for the gas being C2H2.

Acetylene gas is recognised as having a high level of flammability, as well as instability. Being an unstable, flammable gas, acetylene can decompose and cause serious hazards that can damage people, property and the environment.

Flammable gases are a popular choice for fuel in businesses.

Some key hazards associated with acetylene and its use are fires, explosions and asphyxiation. Due to these hazards, it’s important that acetylene is kept and handled in the right way to reduce the likelihood of these incidents occurring.

IMPORTANT: Acetylene cylinders contain a mixture of acetylene and a solvent, such as acetone, to stabilise the substance. Special metal cylinders are required for acetylene storage, as a porous mass is necessary for the safe storage of this gas.

Applications for Acetylene

Around one-fifth of the world’s acetylene is used for oxyacetylene gas welding and cutting. Oxyacetylene is recognised as the hottest burning fuel gas and the third hottest natural chemical flame.

Further applications for acetylene include use in mining headlamps, streetlights, lighthouses and other lighting applications – usually in situations where there’s the need for portable lighting or a lack of capability to connect with the electric grid.

Welding is one of the most common applications for acetylene gas in the workplace.

Acetylene has also been used as a chemical feedstock for polyethylene plastics, however, the environmental implications have diminished the demand for this application.

DID YOU KNOW? Acetylene gas is often used in underground operations, such as mining applications, as the gas is light and doesn’t accumulate in low areas. This prevents the risk of asphyxiation in these particular types of circumstances.

Is Acetylene a Dangerous Good?

Acetylene is most certainly a dangerous good. So, if you’re working with acetylene, it’s vital that it’s handled and stored in the correct way to minimise risk. Acetylene is recognised as a Class 2, Division 2.1 Flammable gas.

This class of dangerous goods has specific divisions which are explained in the Australian Dangerous Goods (ADG) Code:

Class 2: Gases Division

2.1: Flammable gases

2.2: Non-flammable, non-toxic gases

2.3: Toxic gases

IMPORTANT: Due to its highly flammable nature, acetylene is manufactured with an odour, so it can be easily detected if there’s a gas leak. A gas leak can result in the ignition of the substance, as well as toxic gas inhalation.

What are the Dangers Associated with Acetylene Gas?

Acetylene is a Division 2.1 Flammable gas, which means that it can explode under certain conditions.

These unsafe conditions include keeping an acetylene cylinder near:

- Heat

- Ignition sources

- Incompatible substances

This gas is inherently unstable and has a risk of decomposition. This chemical reaction can cause devastating explosions, that puts your people and property at great risk. If cylinders are not handled safely, the impact damage can spark the decomposition process.

There is also the risk that acetylene can cause human harm, due to the toxic properties in the gas. As with any gas, if there is a leak, it’s vital that staff don’t breathe in the air while the situation is being rectified. The use of PPE in such a situation is vital for the safety and health of staff.

REMEMBER: As with all dangerous goods, the separation of incompatible substances is vital for the safety of your staff and organization in general. Acetylene must be stored separately from incompatible substances, including oxygen, which is a non-flammable, oxidising gas.

Example of an Acetylene Explosion

To illustrate how easy a cylinder of acetylene can cause incredible harm, we have highlighted an incident that took place in England at a plant hire business.

Deadly acetylene cylinder explosion, England

An inquest into the death of an employee at a plant hire business in Durham, England, revealed that acetylene was being carried in an enclosed van, with inadequate ventilation. This caused a massive explosion of molten metal and glass which instantly killed the employee and destroyed homes and shops nearby.

The vehicles in the business had not been properly modified for the transit of acetylene. The owners were found to have not conducted the necessary risk assessments in relation to the country’s Health and Safety Act.

REMEMBER: Acetylene bottles should be carried in open-topped vehicles or those equipped with adequate ventilation, to mitigate the risk of gases causing explosions.

Considerations for Storage and Handling

Due to the risks associated with this gas, there are many requirements for its storage and handling in Australian workplaces. Although acetylene is a dangerous substance, with the correct measures in place, you can safely work with acetylene without the risk of human harm, fire or explosion hazards.

Some of these key considerations include:

Isolation of Ignition Sources

As this gas is regarded as highly flammable, it must not be stored or handled near any type of ignition source. This includes obvious sources of ignition – such as flames or hot surfaces – as well as less obvious ignition sources, such as mobile phones or power points.

Cylinder Restraints

To stop cylinders from toppling over and leaking flammable, hazardous gases into the workplace, the proper restraints are necessary for storage. The restraints prevent cylinders from becoming damaged, which can assist with preventing decomposition, as well as an accidental release of gas under pressure.

REMEMBER: When moving cylinders around the worksite, make sure they are suitably restrained. Many accidents occur when staff are transporting compressed gas cylinders around a workplace. Instead, opt for a compliant gas bottle trolley to prevent impact damage and the subsequent hazards.

Upright Storage

You must never allow your cylinders, when they’re being handled, stored, transported or used, to be placed in any other position but upright. Due to the special cylinder, that contains the mixed acetylene substance as well as the porous mass, the cylinder has to be stored upright to stop the gas separating from the solvent (ie. acetone). If cylinders are being moved or received, they must be left to rest for at least one to two hours.

A gas store must secure the cylinders upright with restraints, as well as provide adequate ventilation so that gases can not accumulate.

Adequate Ventilation

The appropriate ventilation is required for the storage of any type of gas. However, due to the health and explosion hazards of acetylene, it’s highly important to ensure that your bottles are stored outside. This will reduce the risk of the gas accumulating in the workplace, or travelling near an ignition source which could create an explosion.

Segregation of Flammable Gases

Even though these gases are part of the same Class, they each have particular chemical and physical properties for their handling and storage. Never assume that gases are compatible with each other, as Class 2.1 Flammable gases must be kept apart from a range of dangerous goods.

Separate your acetylene cylinders from other incompatible dangerous goods including (but not limited to):

- Division 2.2 Non-flammable, non-toxic gases

- Class 3 Flammable Liquids

- Division 4.1 Flammable Solids

- Division 4.2 Spontaneously Combustible

- Division 4.3 Dangerous When Wet

- Division 5.1 Oxidising Agents

- Class 6 Toxic Substances

- Class 8 Corrosive Substances

REMEMBER: Don’t rely solely on the segregation distances for the storage of incompatible substances. You must also read the Safety Data Sheet for each particular gas or chemical product to determine how to store and handle the products safely.

Dangerous Goods and Hazard Signage

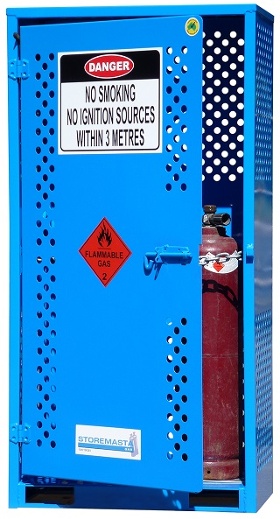

To notify staff, site visitors and emergency services of the hazards associated with acetylene in storage, it’s essential to have the correct signage displayed.

Your gas cylinders must be stored with the correct dangerous goods signage, as well as hazard signage that prohibits the introduction of ignition sources into the area.

Required signage includes the:

- Flammable Gas 2 dangerous goods diamond

.png?width=180&height=180&name=flammable-gas%20(2).png)

- No smoking, no ignition sources within 3m sign

REMEMBER: Storemasta provides a full gas risk management solution with gas stores for all workplaces, gas trolleys for safe handling and transport, plus all the gas diamonds and hazard signage. Shop today.

Storing Dangerous Gases

To find out more about increasing safety in your operations, why not access our FREE eBook? Gas cylinder storage: Compliance and Safety Requirements will lead you through all the necessary considerations if you’re storing any type of compressed gas, including flammable gases such as acetylene. Grab your copy now to learn more.

Living life by the 4 C’s of marketing – communication, coffee, compliance… and more coffee – Leisa Andersen is Storemasta’s Content Marketing Manager. When she’s not writing, you’ll find her enjoying all the good things in life, including shopping, travel and gluten free donuts.