As a follow-up to our post 5 high risk uses of flammable liquids cabinets we see all the time, we’re taking a look at another 6 high risks uses of flammable liquids cabinets. We want you to get the most out of your flammable storage cabinet, so we urge you – PLEASE – don’t do any of these things!

Across Australia, New Zealand and South-East Asia, our Dangerous Goods Specialists have installed safety cabinets in all types of workplaces across the globe. And it always startles us when we see unsafe storage practices that undermine the safety and effectiveness of our innovative flammable liquids cabinets.

So, if you want to know what not to do with your cabinet, read on and learn more about the unsafe practices that we don’t want you to do at your workplace.

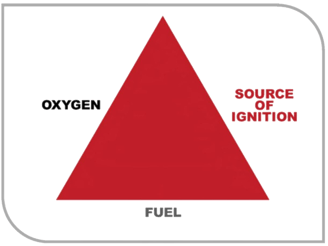

1. Install Flammable Cabinets Next To An Ignition Source

Flammable liquids. Yep, that means that your stores of flammable liquids have the capabilities to ignite when they reach their flash point temperature.

So, it’s only common sense to acknowledge that your flammable liquids cabinet should not be located near an ignition source. However, it’s not always easy to determine what an ignition source is.

Ignition sources can include a vast range of items across the broad categories of thermal, electrical, mechanical and chemical ignition sources.

Some commonly found ignition sources in workplaces can include:

- Power points.

- Electrical equipment/machines that produce heat, sparks or flames.

- Anything that generates static electricity, including personal electronics.

- Maintenance or hot work eg, welding, grinding, soldering, cutting.

Our team at STOREMASTA commonly see workplaces that have installed flammable cabinets next to a 240-volt power point — and they’re in the dark about just how dangerous a practice this is. We’ve also seen worksites that allow vehicular repairs or welding to be conducted near their safety cabinets.

Never place your flammable cabinet close to an ignition source.

Never place your flammable cabinet close to an ignition source.

If you have a flammable cabinet in your workplace, make sure you don’t do any of this!

It’s a requirement of the Australian Standard AS 1940:2017 - The storage and handling of flammable and combustible liquids, that no ignition sources are within a 3 metre radius of your flammable liquids storage cabinet or store. If you have an ignition source within close proximity to your flammable cabinet, you’ll not only be in breach of the standard, but you’ll be putting your organisation at risk of fire and explosion.

WHAT NOT TO DO #1: Don’t ever allow any type of ignition source to come within 3 metres of your flammable liquid storage cabinets. Train all your staff to understand how to identify a possible ignition source and make sure they never bring one near your flammable cabinets.

2. Overload Your Cabinets

Indoor flammable liquids cabinets that are manufactured to Australian Safety Standards are designed to perform 3 important functions:

- Protect the contents of the cabinet from workplace fires.

- Provide liquid tight spill containment.

- Contain flammable vapours and harmful fumes.

However, if your cabinet is loaded past its capacity rating, these safety functions can’t be guaranteed — and are very often negated. Not only will you be in breach of Australian Safety Standards, you’ll also be creating a WHS compliance risk for your business.

Safety cabinets containing more than 250 litres of flammable liquids must meet additional requirements.

Your 250 litre flammable cabinet must:

- Be constructed from heavy duty steel

- Have a larger capacity spill sump that can contain at least 25% of the aggregate storage capacity of the cabinet.

- Not stand taller than 2 metres from floor level.

- Never be installed against common walls or in public buildings, accommodation outlets, schools, hospitals or aged care residences.

- Only be installed on the ground floor (unless the floor has direct street access).

WHAT NOT TO DO #2: Don’t store more than the approved quantities of flammable liquids inside your safety cabinets. No single flammable cabinet should ever contain more than 850 litres of flammable liquids.

3. Use Indoors Cabinets Outside

An indoor flammable liquids cabinet may only be used outside if it has been manufactured to withstand prevailing weather conditions — and has sufficient impact protection.

Here at STOREMASTA we consider indoor flammable liquid storage cabinets unsuitable for Australia’s harsh outdoor environments.

Our team ask that you don’t transfer your indoor cabinets outside, as they are not manufactured to withstand wind, rain, cyclones, heat or snow. They are also not manufactured to take the impact from falling trees, flying debris or vehicles.

Indoor cabinets shouldn't be installed outdoors as they’re not designed for the climatic conditions and may suffer impact damage

Indoor cabinets shouldn't be installed outdoors as they’re not designed for the climatic conditions and may suffer impact damage

We manufacture a range of indoor cabinets as well as outdoor cabinets. Each type of safety cabinet is specifically designed to minimise the particular risks of that environment — and they should never be used in a way that compromises their integrity and safety.

WHAT NOT TO DO #3: Don’t place indoor flammable liquids cabinets in an outdoor environment. If your organisation does need to store chemicals outside, choose a flammable liquids store that has been purpose-built for outdoor use.

4. Keep Combustible Materials Inside The Cabinet

Our Dangerous Goods Specialists consider it best practice to refrain from placing combustible materials inside your flammable liquid storage cabinet. You don’t want to waste valuable storage space inside a high-tech safety cabinet (that can withstand temperatures of up to 850°C) on items such as paintbrushes, cardboard cartons and cleaning rags.

Keep workplace tools and items in their designated storage space and only store Class 3 Flammable Liquids inside your flammable cabinet. It’s that simple.

WHAT NOT TO DO #4: Don’t keep combustible materials inside your flammable liquids cabinets. Always remember to remove cardboard and plastic packaging from chemical containers before putting them away in your safety cabinets.

5. No Protection From Impact Damage

All safety cabinets, chemical stores and gas bottle cages should be protected from impact. That means protecting your stores of hazardous chemicals from flying debris, dropped tools, construction materials, forklifts or delivery vehicles.

Your Class 3 Flammable Liquids storage cabinet can suffer impact damage including tears, punctures and dents. Any kind of damage to your flammable cabinet can reduce the effectiveness and the compliance of the product.

Make sure your indoor flammable cabinet is located in a safe, protected position

Make sure your indoor flammable cabinet is located in a safe, protected position

Just as we mentioned earlier in the blog, the location of your cabinet is crucial to the effectiveness of your chemical storage solution. Your safety cabinet should be installed on level ground in a safe, protected position. It should be out of the way of any incoming traffic – whether that’s equipment, machinery or vehicles. You must also ensure it’s not in a position that is vulnerable to falling objects or debris.

If your flammable cabinet suffers direct impact, it could:

- Create a fire or explosion.

- Cause a chemical spill if the cabinet walls are torn or punctured.

- Put you in breach of Australia Safety Standards.

WHAT NOT TO DO #5: Don’t put your flammable cabinets under mezzanine floors or overhead construction areas. Instead, make sure that your safety cabinets are positioned in a location that is free from direct impact.

6. Not Having First Aid Facilities and Emergency Decontamination Equipment

Many flammable liquids are corrosive, toxic, and irritating to the skin and eyes. So, if there is a risk of flammable liquids reaching the eyes or skin of your team, you may need to install an emergency decontamination station. These facilities should be installed within a 10 second reach — which is 2–10 metres away from your flammable cabinet.

Decontamination stations for flammable liquids would include (as a minimum) an eyewash unit and emergency shower.

If your organisation doesn’t provide emergency showers, eyewash units and first aid facilities close to your cabinet it can result in serious hazards, including fatalities.

Not providing these emergency facilities could:

- Lead to the death or critical injury of a worker.

- Put you in breach of WHS Regulations for failing to provide suitable first aid equipment.

- Violate Australian Safety Standards.

WHAT NOT TO DO #6: Don’t forget about providing first aid facilities and emergency decontamination equipment in your workplace. If flammables can make contact with the eyes or skin of your staff, make sure you install a safety shower, eyewash station and first aid kit within 2–10 metres of each flammable cabinet.

How are You Using Your Flammable Liquids Cabinets?

Buying a safety cabinet manufactured to Australian Safety Standards is only the first step in ensuring chemical safety for your workplace. Where you install your cabinet, how you use it and how you choose to maintain it — are all factors that can greatly affect the safety and compliance of the product.

If you want to get the most out of YOUR flammable liquids cabinets, why not check out our handy eBook? Essential Considerations When Storing Flammable Liquids Indoors is a useful guide for selecting and installing a cabinet for your Class 3 Flammable Liquids. Our eBook is also packed with simple and practical advice — that you can easily apply to your very own business. You can access our eBook for free today by simply clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.