Oxidising agents are substances with the ability to oxidise other substances. This means that they can chemically react when they combine with oxygen. Oxidising agents are classified as Division 5.1 Dangerous Goods. When you’re working with any class of dangerous goods, it’s crucial that you understand the chemical and physical properties of the substance, so you can actively reduce risk. This post will look at the definition of oxidising substances and explain some common oxidising reactions, the chemical risks, and how you can control them.

Defining Oxidising Agents

To provide a definition of oxidising agents, we’ll refer to the Australian Dangerous Goods (ADG) Code defines. The code explains that:

Division 5.1 Oxidising Substances

"Substances which, while in themselves not necessarily combustible, may, generally by yielding oxygen, cause, or contribute to, the combustion of other material. Such substances may be contained in an article;"

Oxidising substances can be further classified in terms of oxidising solids and oxidising liquids. Some common examples of oxidising substances that may be found in the workplace include bromine, hydrogen peroxide, sodium perchlorate, chromic acid and dibenzoyl peroxide. This class of dangerous goods is often used for purposes such as bleaching, water purification and for fertiliser products.

Oxidising substances may contribute to the combustion of other material.

What Happens When a Substance is Oxidised?

So, what exactly occurs when a substance is oxidised? Analytical chemistry provides us with a broader answer: The oxidising agent — also known as the oxidising chemical, oxidant, oxidiser, or electron acceptor — causes the other substance to lose electrons.

Some examples of oxidising agents are halogens, potassium nitrate, and nitric acid.

Common Oxidising Reactions

The process of oxidising occurs side-by-side with reduction. These chemical reactions are known as redox (reduction-oxidation) reactions.

In a redox reaction involving two reactants, one will be oxidised and the other will be reduced. This reaction may happen under heating, or it may be completely spontaneous, therefore safe chemical storage cabinets are top priority when storing oxidants.

Without the appropriate Class 5.1 storage, an oxidising reaction will produce heat and gas. This can lead to a fire or explosion if the substances aren’t contained in a compliant cabinet.

Compliant storage of oxidising agents is required to control the risk of oxidising reactions.

The Risk of Oxidising Agents

Spontaneous fires present a threat to the environment and the safety of people and property in the immediate area of the reaction.

The fires that result from unsafe storage of oxidising chemicals can have consequences ranging from third-degree burns to fatalities.

Fires can destroy work equipment, inventory and employees personal belongings. As with other dangerous substances such as flammable liquids, improper storage can come at a high cost practically and financially.

The risk of fire is a key concern when handling and storing oxidising agents in the workplace.

As well as fire hazards, exposure to oxidising agents by ingestion, inhalation or contact with the eyes or skin can be toxic to human health.

Some oxidising agents are also corrosive which means they have the ability to destroy metal, stone and human flesh by corrosion.

Oxidising Agent Storage Standards

The ADG Code specifies the standards and technical requirements for the land transportation of dangerous goods throughout Australia. Although this code was developed specifically for Australia, its structure, format, definitions and concepts were adopted from the United Nations Recommendations on the Transport of Dangerous Goods.

The code includes but is not limited to classification in:

- Packaging and performance testing of dangerous goods

- Transfer of bulk dangerous goods

- The use of bulk containers

- Dangerous goods documentation

- Safety equipment

- Procedures during transport emergencies

With regards to oxidising chemicals, you can refer to the Australian Standard AS 4326-2008 - The storage and handling of oxidising agents, for requirements on safe oxidising agent storage.

Storing Oxidising Agents

AS 4326-2008 outlines the correct methods for storing and handling oxidising agents.

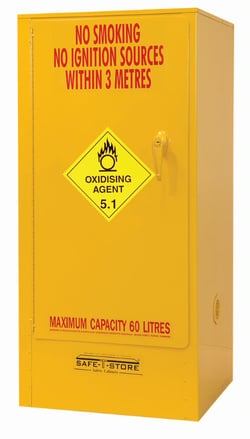

A vital part of this standard ensures that all cabinets and stores used to store oxidants conform to Australian Dangerous Goods Code.

The main factors required for oxidising agent storage to comply with AS 4326-2008 are:

- Cabinets are made in such a way that their contents are secured from outside contamination and pose no risk of a dangerous reaction.

- Each cabinet holds no more than the permitted maximum amount of oxidising agent.

The maximum quantity of oxidising agents allowed to be stored in a single cabinet depends upon whether the cabinet will be located indoors or outdoors. An indoor storage cabinet may hold no more than 250L/kg of an oxidising chemical. The limit for an outdoor storage cabinet is considerably higher, at 850L/kg.

You should consider your storage requirements before you purchase and install Class 5.1 cabinets or outdoor storage containers to ensure that you’re meeting the requirements of the Australian Standards including maximum capacities.

You must consider the outdoor chemical storage capacities when you’re storing Oxidising Agents.

Class 5.1 Cabinet Construction

Cabinets used to store oxidising chemicals must follow strict requirements in terms of size and construction.

All sides of the cabinet must be made of double-walled sheet steel, with at least 40mm of space between the walls. The space can be filled with a non-flammable material or left empty. If the cabinet has shelves, they should be perforated to allow for free air movement.

If the cabinet requires ventilation, the vents should be directed away from potential ignition sources and areas where people might pass by or stay. Ventilation should also be sufficient to maintain exposure levels to any vapours or dusts in the storage area below recommended workplace exposure standards.

The doors of the cabinet must be self-closing and close-fitting — without air-gaps between the doors and the body of the cabinet. They must also have catches that are not made of plastic or zinc die. These catches must automatically release in case of a build-up of pressure inside the cabinet.

Make sure that your oxidising agents are stored in a cabinet that is compliant with Australian Standards.

AS 4326-2008 also requires the lower compound of indoor storage cabinets to be at least 150mm deep and big enough to hold at least 25% of the total storage capacity. The sump must also be liquid-tight to prevent spills from contaminating the workplace.

Keeping Your Workplace Safe From Oxidising Reactions

Oxidising agents are classified as dangerous goods according to the ADGC. This chemical class requires special storage requirements to ensure that they pose no risk to the people and property in your workplace.

To find out more about oxidising agents and how to safety segregate them from other classes of dangerous goods, please access our free eBook. Our easy-to-read guide will help you learn more about the correct method of chemical segregation, so you can avoid issues such as oxidising reactions. Grab your copy today by simply clicking on the image below.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.