If your organisation uses organic peroxides in a manufacturing process, it’s very important that you store and handle these dangerous goods in a way that minimises the harm that they pose to the people and property of your organisation. Safe storage and handling practices are a necessity as organic peroxides have many dangerous properties, which can create severe chemical reactions in a work environment.

REMEMBER: When storing organic peroxides, make sure you’re using compliant storage equipment that offers sufficient ventilation for your Class 5.2 substances.

Defining Organic Peroxides

These dangerous properties are outlined in the definition of organic peroxides given by the Australian Dangerous Goods Code.

Organic Peroxides are defined as:

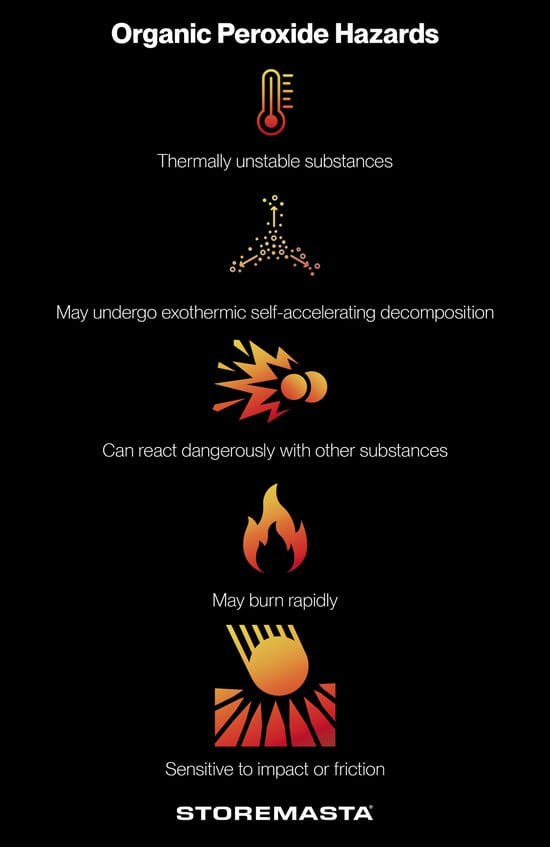

Division 5.2 Organic Peroxides are organic substances which contain the bivalent -0-0- structure and may be considered derivatives of hydrogen peroxide, where one or both of the hydrogen atoms have been replaced by organic radicals. Organic peroxides are thermally unstable substances, which may undergo exothermic self-accelerating decomposition.

In addition, Class 5.2 Organic Peroxides must have one or more of the following properties:

- be liable to explosive decomposition;

- burn rapidly;

- be sensitive to impact or friction;

- react dangerously with other substances;

- cause damage to the eyes.

Is Organic Peroxide Flammable?

One of the most common questions we get asked in relation to Class 5.2 substances is ‘are organic peroxides flammable?’ Organic peroxides can burn rapidly, as well as be susceptible to explosive decomposition and reactions with other substances. This makes organic peroxides highly flammable substances. Ignition sources, heat, shock, contamination or exposure to organic compounds can result in a fire — some with a flare-burning effect.

Thermally Unstable Substances

As outlined in the definition above, organic peroxides are thermally unstable substances and they may undergo exothermic chemical decomposition. When a substance undergoes chemical decomposition, the single chemical compound breaks down into two or more simpler chemical compounds.

The simpler chemical compounds that are produced from chemical decomposition can sometimes be toxic or flammable gases. These toxic or flammable gases can have severe effects upon the people and property of your organisation. Flammable gases have the risk of causing uncontrollable fires and toxic gases are harmful to human health when inhaled.

When organic peroxides undergo exothermic chemical decomposition, they produce heat. This heat can accelerate the chemical decomposition reaction. When the heat energy produced from the chemical decomposition reaction is greater than the heat removal, it will cause the organic peroxide to undergo self-accelerating decomposition. This process can cause the organic peroxide to explode, harming people and property.

Organic Peroxide Storage Cabinets

When storing any type of dangerous goods in the workplace, it’s essential that your storage facilities are designed and constructed to mitigate the risks associated with your chemicals.

When it comes to organic peroxide storage, the use of indoor Class 5.2 safety cabinets is an ideal solution. Organic peroxide storage cabinets offer a range of controls including:

- Durable construction with double walled sheet steel

- Thermic air barrier to offer protection from excessive heat and fire

- Sequential door closing system to contain vapours and minimise human errors

- Doors that automatically release if there is a build-up of pressure within the cabinet

- Liquid tight spill containment sump to contain leaks and spills

REMEMBER: Refer to your safety data sheets to determine the personal protective equipment required for working with organic peroxides. With the correct PPE, your staff may be exposed to the hazards associated with organic peroxides.

Ventilating an Organic Peroxide Safety Cabinet

The risk of being harmed from the inhalation of dangerous gases or an explosive decomposition of organic peroxides can be controlled through effective storage. An important part of this storage process will be the ventilation of your organic peroxide storage cabinets.

A ventilation system for organic peroxide storage cabinets will remove the toxic, flammable and corrosive gases and maintain a consistent temperature inside the cabinet. A consistently low temperature is critical for avoiding the risk of explosive decomposition.

To ensure safety for workplaces carrying organic peroxides, the Australian Standards has provided detailed guidance regarding all handling and storage practices. The Standard that outlines the requirements for ventilating organic peroxides storage cabinets is AS 2714 - The storage and handling of organic peroxides. We’ll discuss the requirements of this standard in more detail below.

Ventilation Requirements According to AS 2714

Section 4.6 of the Australian Standard for organic peroxides states the following in relation to ventilation requirements for indoor chemical storage cabinets:

4.6 ADDITIONAL REQUIREMENTS FOR INDOOR STORAGE CABINETS

4.6.1 Cabinet design and construction

The following requirements apply:

(g)The cabinet shall be ventilated in accordance with Clause 4.5.2. Where the cabinet is vented to the atmosphere, ducting shall be designed to prevent back-pressure and shall be directed away from any ignition sources and areas where people congregate.

To clarify the above requirement, clause 4.5.2 states that:

4.5.2 Ventilation

A store for organic peroxides (other than for those requiring refrigeration, as covered by Clause 4.5.5) shall be provided with ventilation at high and low levels, in order to prevent the build-up of flammable or toxic vapours and to assist in maintaining an even temperature.

As this Standard states that “the cabinet shall be ventilated” it means that ventilation of dangerous goods storage cabinets used for the storage of organic peroxides is a mandatory requirement.

Your mechanical ventilation system should be compliant and meet the requirements of the Australian Standards.

Therefore, if you are using chemical storage cabinets for the storage of organic peroxides, they must be ventilated to reduce the concentration of dangerous vapours to a safe limit. This will reduce the risk of the flammable vapours coming into contact with ignition sources, as well as preventing workers from becoming intoxicated from the inhalation of toxic vapours.

Compliant Ventilation System for Organic Peroxide Storage Cabinets

When you install a ventilation system on compliant storage, it’s very important to ensure that your ventilation system doesn’t pose any further risks to the people and property of your organisation. This means that you’ll have to ensure that the features of your mechanical ventilation system meet the requirements of the Australian Standards.

A safe and complaint ventilation system for organic peroxide storage cabinets must follow the requirements outlined below:

- Class 5.2 Organic Peroxide mechanical ventilation systems should be designed so that it prevents any vapours from escaping into the room.

- The ventilation system shall be vented to the outside atmosphere in a location that is safe to disperse corrosive vapours. A safe location will be away from places where people congregate and any possible ignition sources.

- The air inlet shall be attached to the vent port at the top of the cabinet and the dangerous vapours shall be extracted from the bottom vent port via the exhaust fan. This configuration is most effective as most dangerous vapours are heavier than air and reside in the bottom of the cabinet.

- A ventilation system cannot be linked to multiple cabinets. A ventilation system connected to multiple cabinets could cause vapours from incompatible dangerous goods to mix, resulting in violent chemical reactions.

- When a mechanical ventilation system is not attached to a cabinet, the vent bungs must be tightly screwed into the vent ports. This stops any toxic and flammable vapours from escaping into the workplace.

- In all instances the ventilation system shall not compromise the structural integrity of the cabinet.

- The ventilation duct shall not be smaller than the size of the venting opening on the side of the cabinet. A ventilation system shall be designed by an appropriately qualified engineer and it shall comply with AS/NZS - 1668.2-2002.

- The diameter of the ducting should be no smaller than the vent opening on the cabinet.

- If the organic peroxide being stored produces corrosive vapours, the exhaust fan used to extract the vapours must be corrosive resistant. This ventilation system will need to have corrosive resistant blades, shrouds and ducting.

- If the organic peroxide that is stored produces flammable vapours, the exhaust fan will need to be intrinsically safe.

Class 5.2 Organic Peroxide Storage Safety

As we’ve highlighted in this post, compliant storage and ventilation can ensure that your organic peroxides are stored carefully. Due to these goods being thermally unstable, it's vital that indoor Class 5.2 Organic Peroxides storage cabinets are ventilated. The mechanical ventilation system will safely extract any toxic and flammable vapours, while keeping the temperature inside the cabinet at a consistently low level.

For further information on how to ventilate dangerous goods storage cabinets, why not download our free eBook? Our guide will run you through the requirements that apply to all the dangerous goods classes at your site, so you can create a safe and compliant work environment. Grab your free copy today to find out more.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.