When you’re using different dangerous substances in the workplace, it’s essential that they’re handled and stored in a manner that that minimises risk. One of the most significant risks when storing multiple classes of dangerous goods is the chemical reactions and hazards that can occur when incompatible substances make contact. Two commonly used classes of dangerous goods that have the potential to react dangerously are Class 3 Flammable Liquids and Division 5.1 Oxidising Agents. In this post, we’ll be looking at how flammable liquids and oxidising agents can cause harm within your organisation. But let’s first have a look at the definition of theses goods as per the Australian Dangerous Goods (ADG) Code.

Class 3 Flammable Liquids

According to the Australian Dangerous Goods Code, flammable liquids are defined as:

Flammable liquids are liquids, or mixtures of liquids, or liquids containing solids in solution or suspension (for example, paints, varnishes, lacquers, etc., but not including substances otherwise classified on account of their dangerous characteristics) which give off a flammable vapour at temperatures of not more than 60 °C, closed-cup test, or not more than 65.6 °C, open-cup test, normally referred to as the flash point. This class also includes:

- liquids offered for transport at temperatures at or above their flash point; and

- substances that are transported or offered for transport at elevated temperatures in a liquid state and which give off a flammable vapour at a temperature at or below the maximum transport temperature.

Division 5.1 Oxidising Agents

According to the Australian Dangerous Goods Code, Oxidising Agents are defined as:

Substances which, while in themselves not necessarily combustible, may, generally by yielding oxygen, cause, or contribute to, the combustion of other material. Such substances may be contained in an article;

How Flammable Liquids and Oxidising Agents React Dangerously

For combustion to successfully take place there are three critical elements required. These elements include:

- Fuel (flammable liquid)

- Oxygen (oxidising agent)

- Heat

When the flammable liquids and oxidising agents are mixed, it will produce an extremely flammable mixture of substances. If an ignition source, such as a spark, hot surface or electrical current, came into contact with this flammable mixture, it would ignite instantaneously.

Oxidising agents provide excessive amounts of oxygen to enrich flammable and combustible substances. This causes them to ignite at much lower temperatures than they would normally. To avoid these dangerous reactions, it’s crucial that flammable liquids and oxidising agents are segregated during handling and storage.

Segregation According to the Australian Standards

Incompatible classes of dangerous goods can be safely segregated by following the guidelines set out in the Australian Standards. The Australian Standard that outlines the requirements for storing incompatible classes of dangerous goods is, AS 3833 - The storage and handling of mixed classes of dangerous goods. This standard contains a Dangerous Goods Segregation Chart that outlines the separation distances for storing incompatible classes of dangerous goods.

This segregation chart from AS 3833 interprets that:

“When Class 3 Flammable Liquids and Division 5.1 Oxidising Agents are stored in a common dangerous goods store, they must be segregated by at least 5 metres and kept in separate compounds that don’t share a common drainage system.”

If you have a common dangerous goods store that contains mixed classes of dangerous goods, you should carry out a dangerous goods risk assessment. This assessment will help you correctly identify all the substances onsite, including those that are flammable liquids and those that are classified as oxidising agents. These substances must then be segregated by at least 5 metres and stored in different compounds that have separate drainage systems.

Grab a FREE copy of our segregation chart

REMEMBER: The Australian Standards provide industry with precise guidelines on how to store and handle dangerous goods in way that minimises risk to people, property and the environment. All Storemasta products are designed and manufactured to meet the strict requirements of the Australian Standards.

Flammable Storage Cabinet Requirements

If you choose to segregate oxidising agents from flammable liquids by using chemical storage cabinets, the cabinet used for the storage of flammable liquids must comply with the requirements outlined in AS1940-2017- The storage and handling of flammable and combustible liquids.

The walls, floor, roof and doors of flammable storage cabinets must have a double walled sheet steel construction. This double walled sheet steel construction provides the cabinet with insulation from ignition sources that could potentially ignite the flammable liquids within the cabinet.

Other construction requirements for flammable storage cabinets include:

- Any gaps between the doors and the walls must be sealed to prevent the spread of flames and heat radiation.

- Any materials that are critical to the structural integrity of the cabinets construction must not melt at temperatures below 850 degrees celsius.

- If the doors of the cabinet must be fitted with a device that keeps them open while in use, the device must automatically release at temperatures exceeding 80 degrees celsius.

- The doors of the cabinet must be self-closing, closing fitting and held shut by at least two catches

- The cabinet shall be designed so that any spills that may occur inside the cabinet are directed into the spill containment sump at the bottom of the cabinet.

- Any shelving inside the cabinet must be perforated to allow for free air-movement

- The base of the cabinet must form a liquid-tight sump with a depth of at least 150mm. The sump should be designed in such a way that packages of flammable liquids are prevented from being stored inside it.

To ensure that everyone in the workplace is aware of the potential risks associated with flammable liquids, all flammable storage cabinets must be marked with clear safety signs. The dangerous goods signage requirements for flammable storage cabinets is outlined below:

Class 3 - Flammable Liquids

No Smoking No Ignition Sources Within 3 Metres

Oxidising Agent Cabinet Storage Requirements

When segregating oxidising agents from flammable liquids using chemical storage cabinets, it’s important to use an oxidising agent storage cabinet that complies with the Australian Dangerous Goods Standards.

The Australian Standard that outlines the requirements for oxidising agent storage cabinets is AS 4326 - The storage and handling of oxidising agents. As 4326, oxidising agent storage cabinets must be constructed with doors that are held shut by catches that automatically release in the event of a build up of pressure.

Other oxidising agent cabinet construction requirements as 4326 include:

- The walls, floor, doors and roof of the cabinet must be constructed from a double walled sheet steel construction. The gap between the walls must be at least 40mm. This gap can be an open air space or filled with non-flammable non-combustible insulation.

- The cabinet must have doors that are self-closing and close-fitting.

- The door catches and hinges must not be constructed from plastics or zinc die castings

- The cabinet must have a lower liquid-tight compound that is at least 150 mm deep and capable of containing at least 25% of the aggregate capacity of the storage cabinet.

- Any shelves within the cabinet must be perforated to allow for free air-movement.

- Where appropriate, oxidising agent storage cabinets must be vented to the outside atmosphere and away from any ignition sources and places where people congregate.

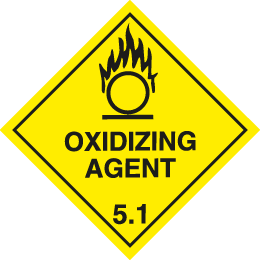

To ensure that everyone in the workplace is aware of the potential hazards associated with oxidising agents, it’s important to display clear safety signage on the front of all safety cabinets used for the storage of oxidising agents. The dangerous goods placarding requirements for oxidising agent storage cabinets is outlined below:

Division 5.1 Oxidising Agents

Ventilation Requirements For Oxidising Agent Storage Cabinets

In addition to the above-mentioned construction requirements, mechanical ventilation systems must be considered when you’re planning to store oxidizing agents.

Ventilation requirements are detailed in AS 4326 - The storage and handling of oxidising agents.

Section 4.8.3 of this standard states:

“Where appropriate, cabinets shall be vented to atmosphere, away from ignition sources and areas where persons are likely to congregate.”

As this standard states that “cabinets shall be vented”, it means that ventilation of oxidising agent storage cabinets is a mandatory requirement. A ventilation system will reduce the concentration of oxidising gases and vapours to a safe limit reducing the risk of unexpected combustion. The workplace exposure standards also apply.

Workplace Exposure Standards

Exposure to any kind of hazardous substances will pose significant health risks upon your workers. Some of these health risks include:

- Asphyxiation

- Vomiting

- Nausea

- Headaches

- Irritation to the eyes, ears and throat

- Dizziness

To help combat these health risks, Safework Australia developed the workplace exposure standards. These exposure standards identify hundreds of hazardous substances and their legal airborne concentration limits.

If the oxidising agent that you are storing is listed in the workplace exposure standards, it’s important to ensure that the ventilation system is capable of keeping the concentration of the oxidising vapours below the maximum legal limit specified in the workplace exposure standards.

What are the Features of a Compliant Ventilation System For Oxidising Agents?

When you install a ventilation system in an oxidising agent storage cabinet, it's important to ensure that it doesn’t pose any further risks to the people in your organisation. A safe and compliant ventilation system for an oxidising agent storage cabinet must be installed in line with the requirements outlined below:

- A mechanical ventilation system should be designed so that it prevents any vapours from escaping into the room.

- The ventilation system shall be vented to the outside atmosphere in a location that is safe to disperse oxidising vapours. A safe location will be away from ignition sources and places where people congregate.

- The air inlet shall be attached to the vent port at the top of the cabinet and the oxidising vapours shall be extracted from the bottom vent port via the exhaust fan. This configuration is most effective as most hazardous vapours are heavier than air and reside in the bottom of the cabinet.

- A ventilation system must not be linked to multiple cabinets. A ventilation system connected to multiple cabinets could cause vapours from incompatible dangerous goods to mix, resulting in violent chemical reactions.

- When a mechanical ventilation system is not attached to a oxidising agent storage cabinet, the vent bungs must be tightly screwed into the vent ports. This stops any oxidising vapours from escaping into the workplace.

In all instances the ventilation system shall not compromise the structural integrity of the cabinet.

In all cases the ventilation duct must not be smaller than the size of the vent opening on the side of the cabinet. A ventilation system must be designed by an appropriately qualified engineer and it must comply with AS/NZS - 1668.2.

Segregating Flammable Liquids and Oxidising Agents Safely

As flammable liquids and oxidising agents form two of the key elements for a combustion reaction to take place, they need effective storage and segregation to keep them stable and safe. Help your staff practice the rules of safe segregation by requesting your free magnetic dangerous goods segregation chart. This handy chart will give you a visual reminder of how to correctly identify and segregate incompatible classes of dangerous goods in your own workplace. Request your complimentary chart for today.

Joining the team as a Dangerous Goods Storage Consultant, Melissa Hampton became Storemasta's Marketing Manager in late 2021. With extensive knowledge and experience in chemical compliance, Melissa is responsible for leading the Marketing team and helping shape their marketing strategy. In her spare time, you can find Melissa hiking, swimming and enjoying the great outdoors in beautiful north-west Tasmania.